Refined glufosinate ammonium-dicamba compound

A technology of compound composition and refined glufosinate-ammonium, which is applied in biocides, animal repellents, plant growth regulators, etc., can solve problems such as short duration of action, need for repeated medication, and incomplete control , to achieve the effects of low cost, obvious marketing value and economic benefits, and a simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

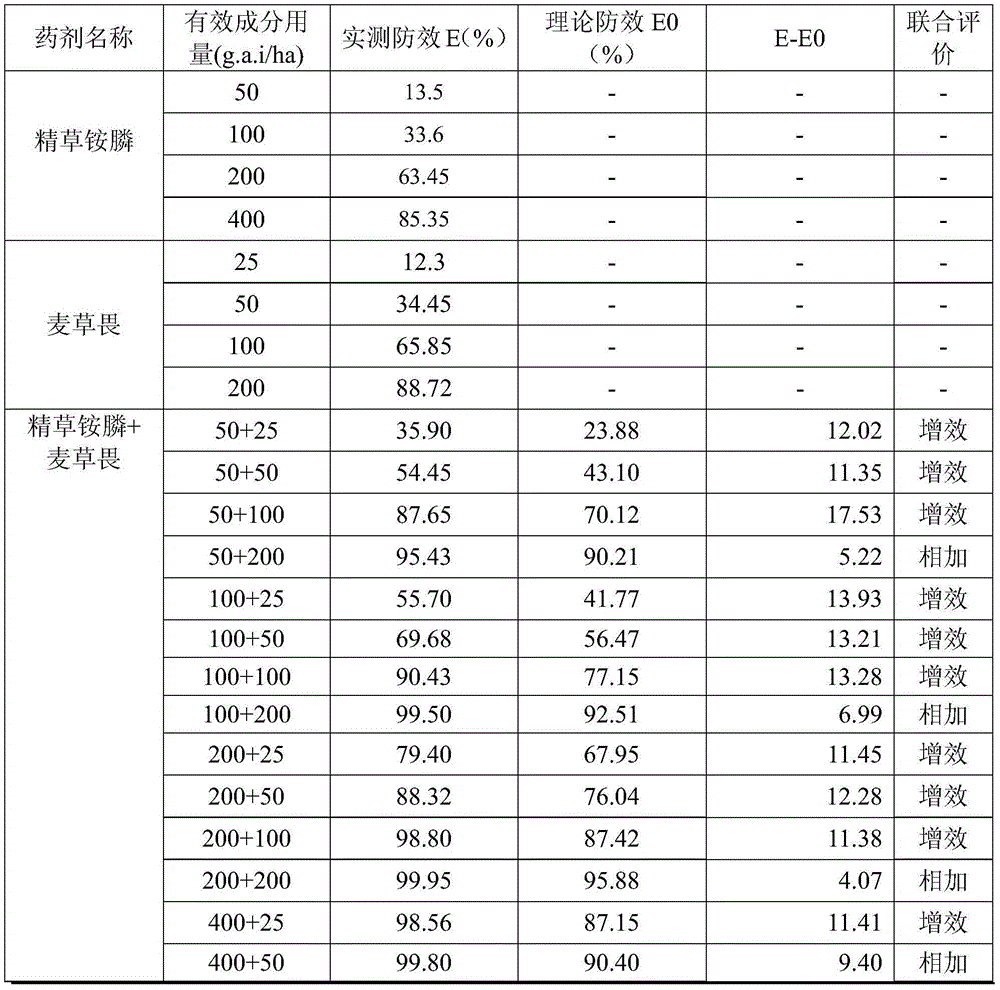

[0044] Experimental report on the activity of the mixture of glufosinate-ammonium and dicamba on weeds

[0045] Purpose of the test: To determine the herbicidal effect of the mixture of glufosinate-ammonium and dicamba on target weeds under potted conditions in the greenhouse, and to evaluate their combined effect.

[0046] Test target: grass weed - goosegrass

[0047] Test method: potted stem and leaf treatment (NY / T1155.4-2006): set soil in a flower pot with a height of 10 cm and a diameter of 10 cm, sow 15-20 weed seeds of the target weed, cover with a thickness of 0.5-1 cm After the weeds grow to the 2-4 leaf stage, the stems and leaves are sprayed with 12mL per spray, repeated 4 times, and a blank control is set up. After treatment, place them in the greenhouse for cultivation, regularly observe the growth of the target weeds, measure the symptoms and inhibition of the target for 15 days, and weigh the fresh weight of the aboveground part or the fresh weight of the plant...

Embodiment 2

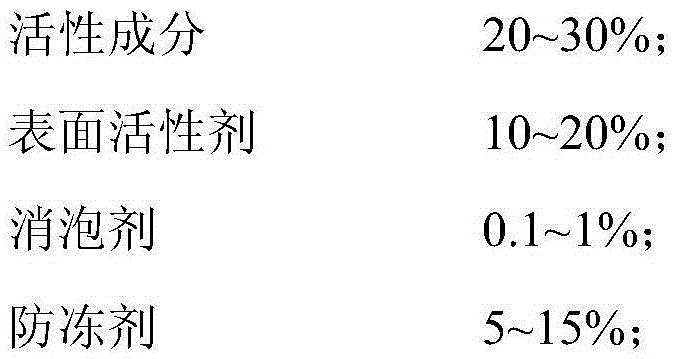

[0058] Example 2. Preparation of 10% refined glufosinate-ammonium + 10% dicamba soluble liquid. The raw material formula is shown in Table 2.

[0059] Table 2

[0060] components

[0061] Add refined glufosinate-ammonium and dicamba into water to dissolve, keep warm at 60°C, stir at 180 rpm until the original drug is completely dissolved, add defoamer and surfactant, stir evenly, cool to room temperature, and prepare 20% Refined glufosinate-ammonium dicamba soluble liquid.

Embodiment 3

[0062] Example 3. Preparation of 5% refined glufosinate-ammonium + 15% dicamba soluble liquid. The raw material formula is shown in Table 3.

[0063] table 3

[0064] components

[0065] Add refined glufosinate-ammonium and dicamba into water to dissolve, keep warm at 60°C, stir at 180 rpm until the original drug is completely dissolved, add defoamer and surfactant, stir evenly, cool to room temperature, and prepare 20% Refined glufosinate-ammonium dicamba soluble liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com