Step-down circuit in medium voltage and high voltage integrated circuit

An integrated circuit and step-down circuit technology, applied in electrical components, output power conversion devices, etc., can solve the problems of large static current, high resource consumption, complex circuit structure and process of the conversion circuit, and achieve low static current consumption, Simple circuit structure, good effect of step-down and voltage regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

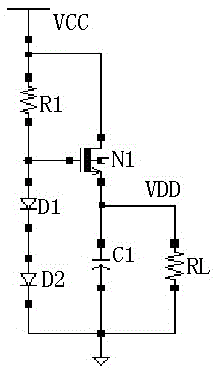

[0012] The first embodiment: a step-down circuit in a medium-high voltage integrated circuit, which includes a MOS transistor N1 and a capacitor C1. It is characterized in that the drain of the MOS transistor N1 is connected to the input terminal VCC of the high-voltage power supply for external power supply, and the source of the MOS transistor N1 The pole is grounded through the capacitor C1, the source of the MOS transistor N1 is the output terminal VDD of the low-voltage power supply to supply power to the internal control circuit part, the substrate of the MOS transistor N1 is grounded, and the gate of the MOS transistor N1 is connected to a control voltage signal. The MOS tube is a high-voltage N-channel consumption or zero-volt intrinsic tube. The control voltage signal is generated by a circuit composed of resistor R1, diode D1, and D2. One end of resistor R1 is connected to the input terminal VCC of the high-voltage power supply, and The other end is connected to the a...

no. 2 example

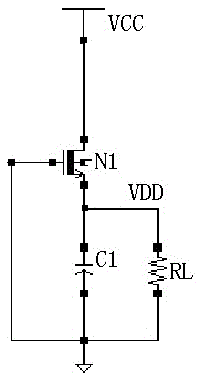

[0020] The second embodiment: when the turn-on voltage Vth of the MOS transistor N1 reaches a more negative voltage (such as -1.5v), within the voltage range of the output terminal VDD, the diode and resistor can be omitted, that is, the gate of the MOS transistor N1 Directly grounded, since there is no diode, the influence of temperature on the whole circuit is almost negligible, and the circuit will become simpler and more reliable.

[0021] It should be noted that, in the current integrated circuit technology, whether it is high voltage or low voltage, the power dissipation device has become one of the commonly used devices. Of course, there are also some low-voltage processes that only provide zero turn-on voltage intrinsic transistors (NativeMOS), which can also be used by using the working principle of this circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com