A cascaded refrigeration cycle system coupled with an ejector

A cycle system and ejector technology, applied in the field of cascade refrigeration cycle systems, can solve the problems of reducing refrigeration capacity, waste, and increasing power consumption of high-temperature stage compressors, so as to improve the heat transfer coefficient, the refrigeration coefficient, and the heat transfer coefficient. The effect of thermal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

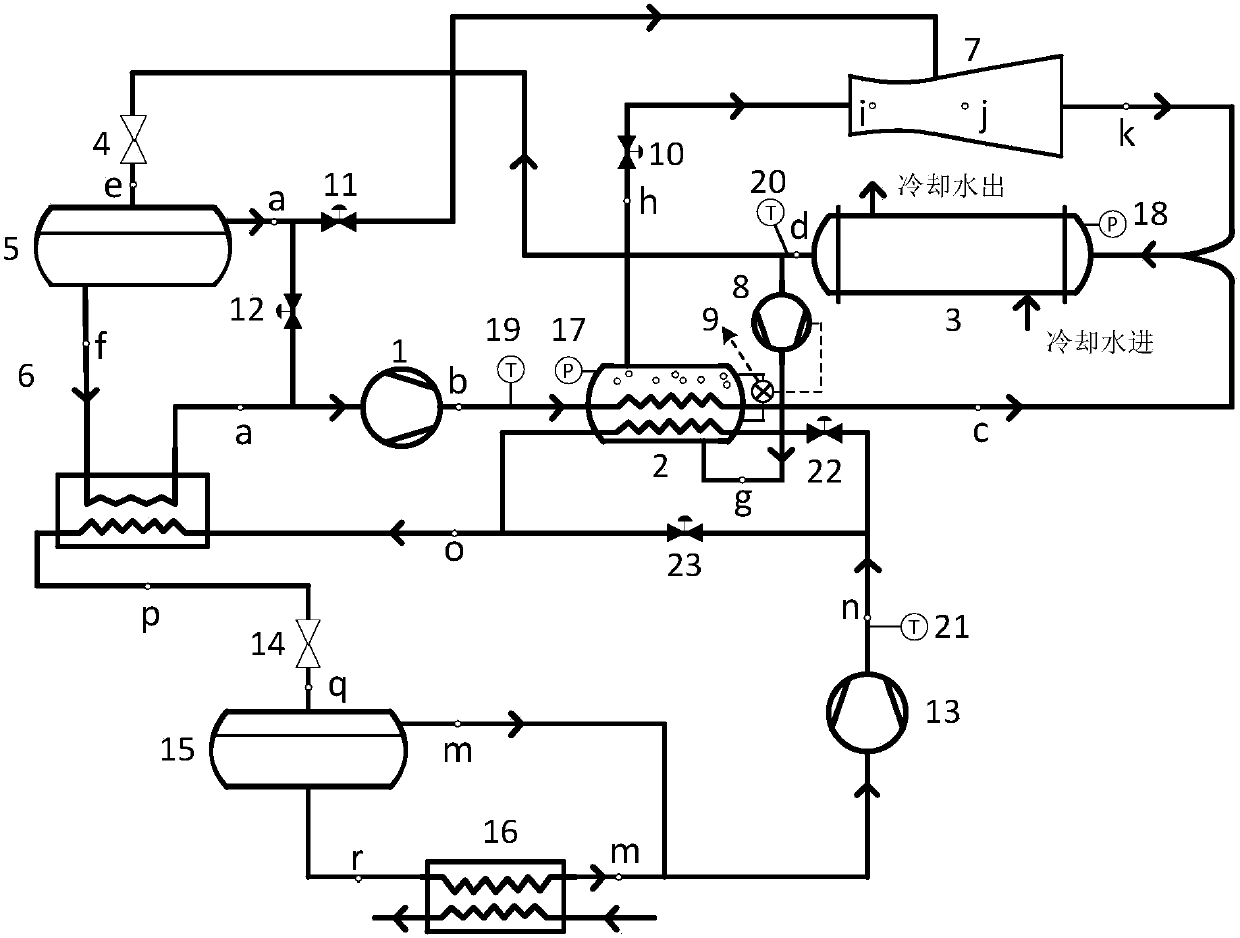

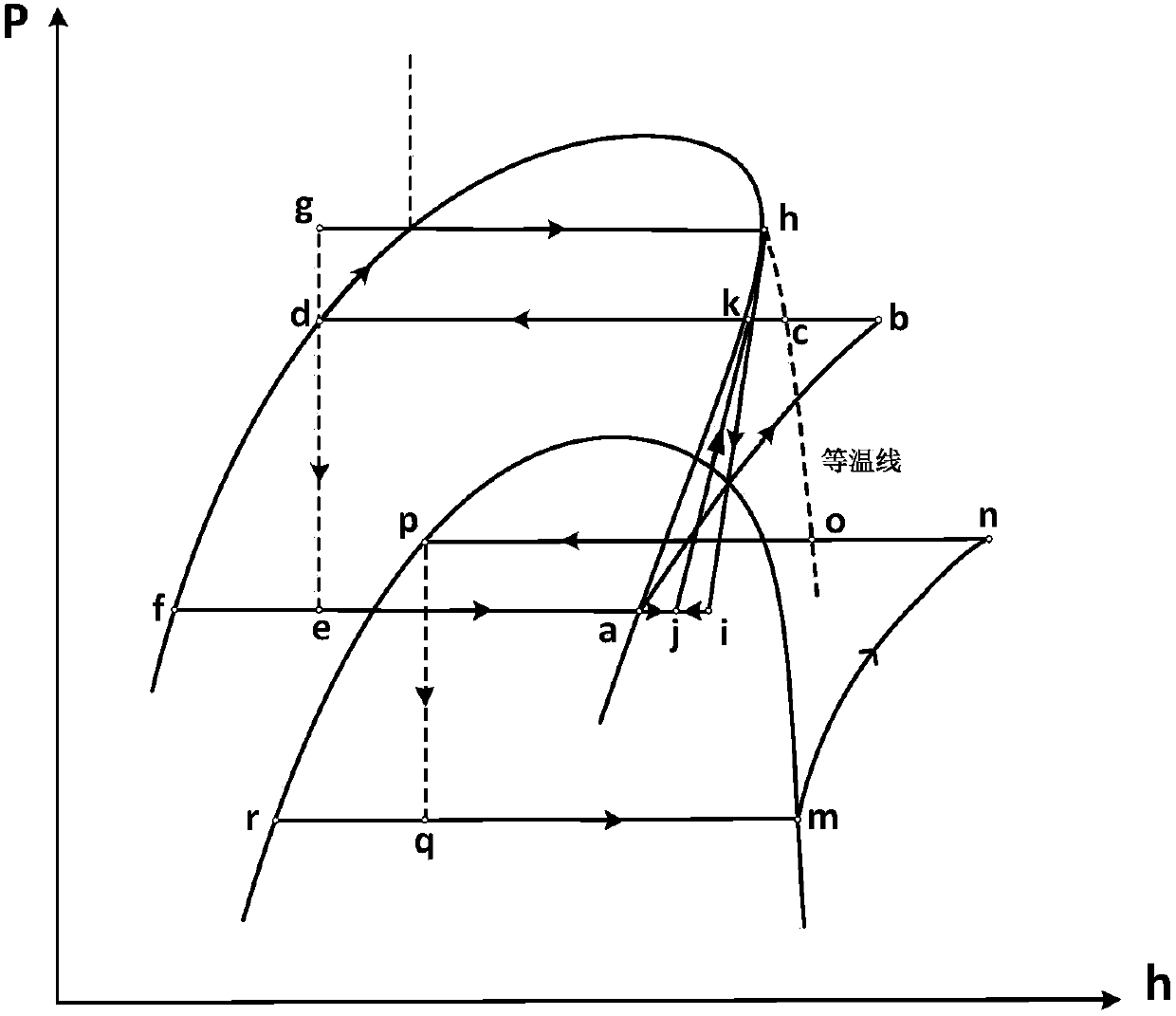

[0016] Such as figure 1 As shown, the cascade refrigeration cycle system that utilizes the exhaust sensible heat of the refrigeration compressor and the coupling of the ejector includes a high-temperature stage compressor, a low-temperature stage compressor, a three-channel generator, a condenser, and a condensation evaporator , throttle valve, gas-liquid separator, evaporator, ejector, liquid booster pump, liquid level controller, solenoid valve, pressure sensor, temperature sensor, etc.

[0017] Its refrigeration cycle method is:

[0018] The saturated liquid refrigerant condensed by the condenser is divided into two paths, one path passes through the throttle valve to reduce temperature and pressure, and the other path passes through the liquid booster pump to pressurize and enter the three-channel generator. The level controls the start and stop of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com