Culvert structure adopting high density polyethylene (HDPE) winding reinforcement pipes and foam concrete and construction method of culvert structure

A technology of winding reinforcing pipe and foam concrete, which is applied in the field of culvert structure, can solve the problems of uneven settlement of culvert pipes, low requirements on ground bearing capacity, and collapse of culvert pipes. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

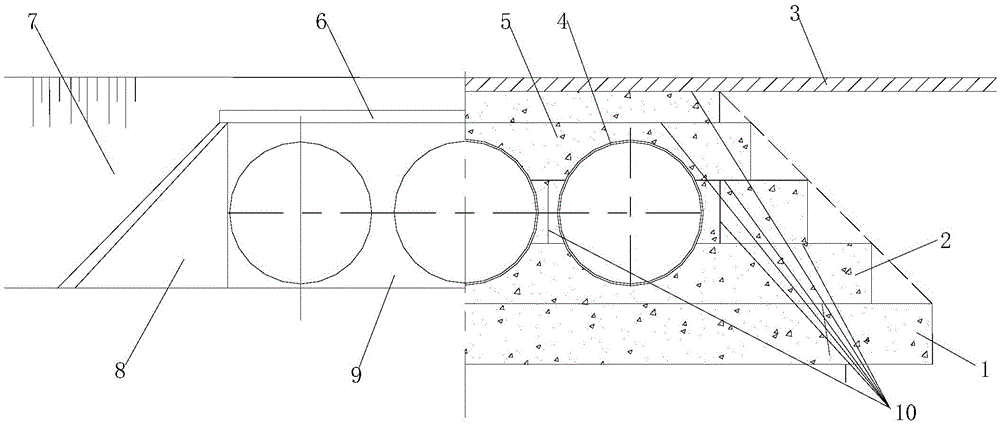

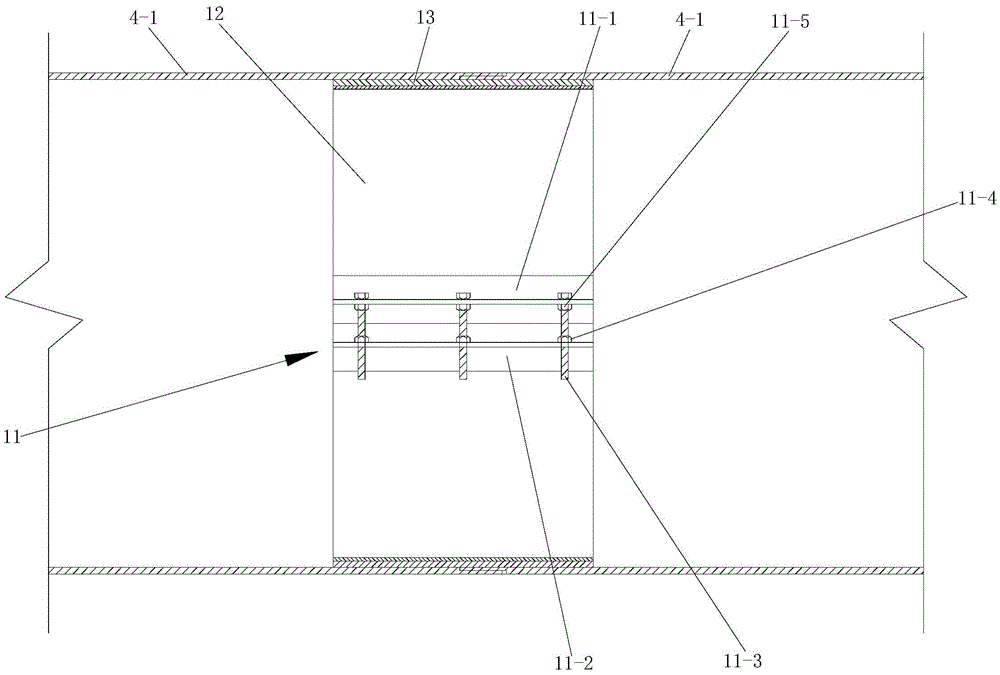

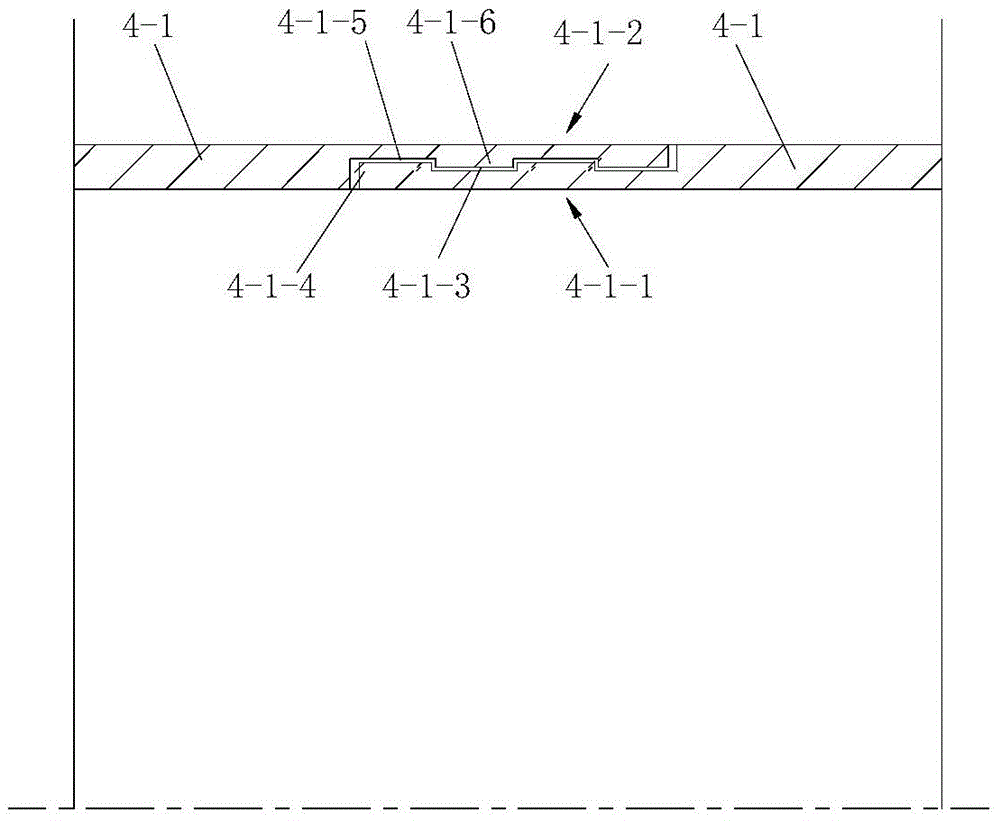

[0055] Such as figure 1 The shown culvert structure adopts HDPE winding reinforced pipe and foam concrete, including culvert pipe foundation 2, culvert pipe 4, filling body 5 located on both sides and above the culvert pipe 4, and road surface 3 above the filling body 5, the filling The body 5 is a foam concrete filling body; the culvert 4 includes a plurality of HDPE winding reinforcement pipes 4-1 connected head to tail in sequence, and the inner side of the connection of two adjacent HDPE winding reinforcement pipes 4-1 is wound with a ring-shaped steel pipe. Belt 12, an anti-seepage sealing structure 13 is arranged between the annular steel belt 12 and the HDPE winding reinforced pipe 4-1, and the annular steel belt 12 is provided with a force applied to it so that the annular steel belt 12, anti-seepage The sealing structure 13 and the HDPE winding reinforcing pipe 4-1 are closely attached to the sealing strengthening device 11 .

[0056] In this embodiment, the foamed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com