A method for separating amphoteric metals in waste circuit boards

A technology for waste circuit boards and amphoteric metals, applied in chemical instruments and methods, improvement of process efficiency, inorganic chemistry, etc., can solve the problems of less research on the separation and recovery of amphoteric metals, high requirements for working environment, poor selectivity of raw materials, etc., to achieve Efficient and clean production, less corrosive equipment, and selective separation of metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

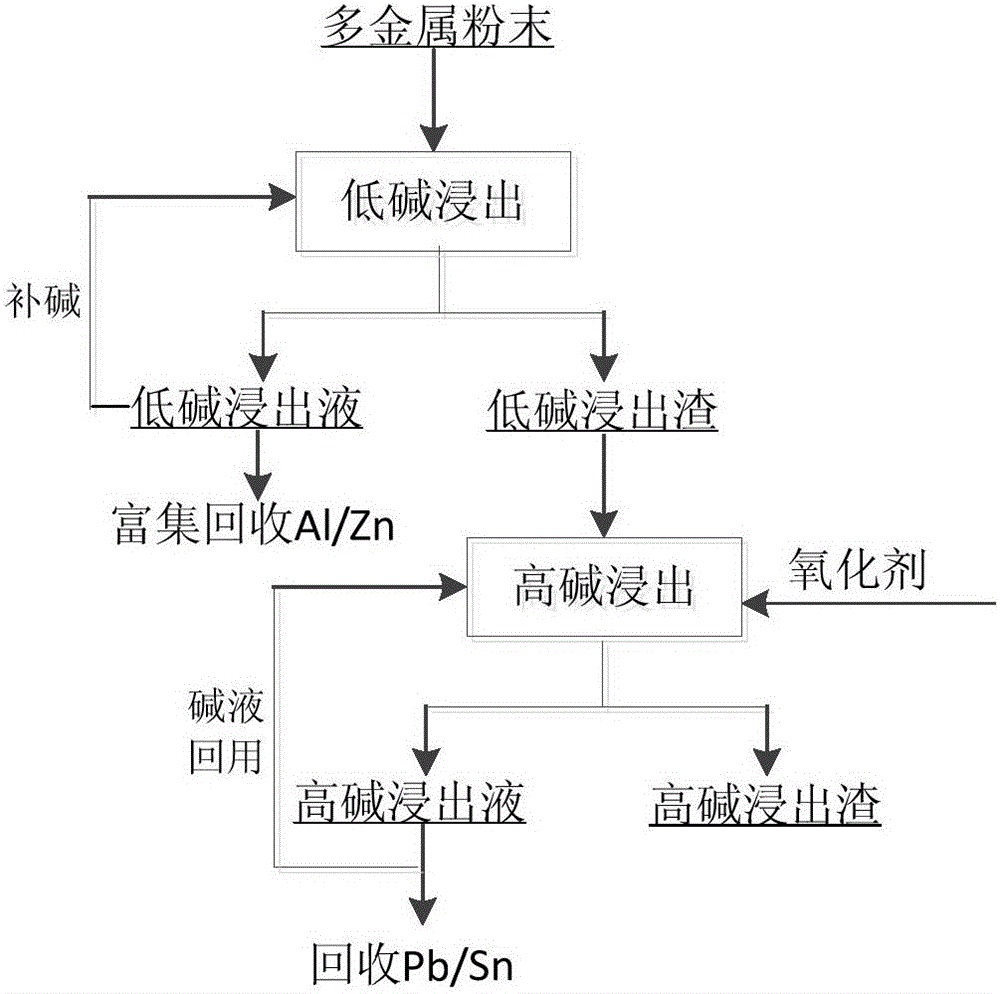

[0037] A method for separating amphoteric metals in waste circuit boards of the present invention, its process flow chart is as follows figure 1 shown, including the following steps:

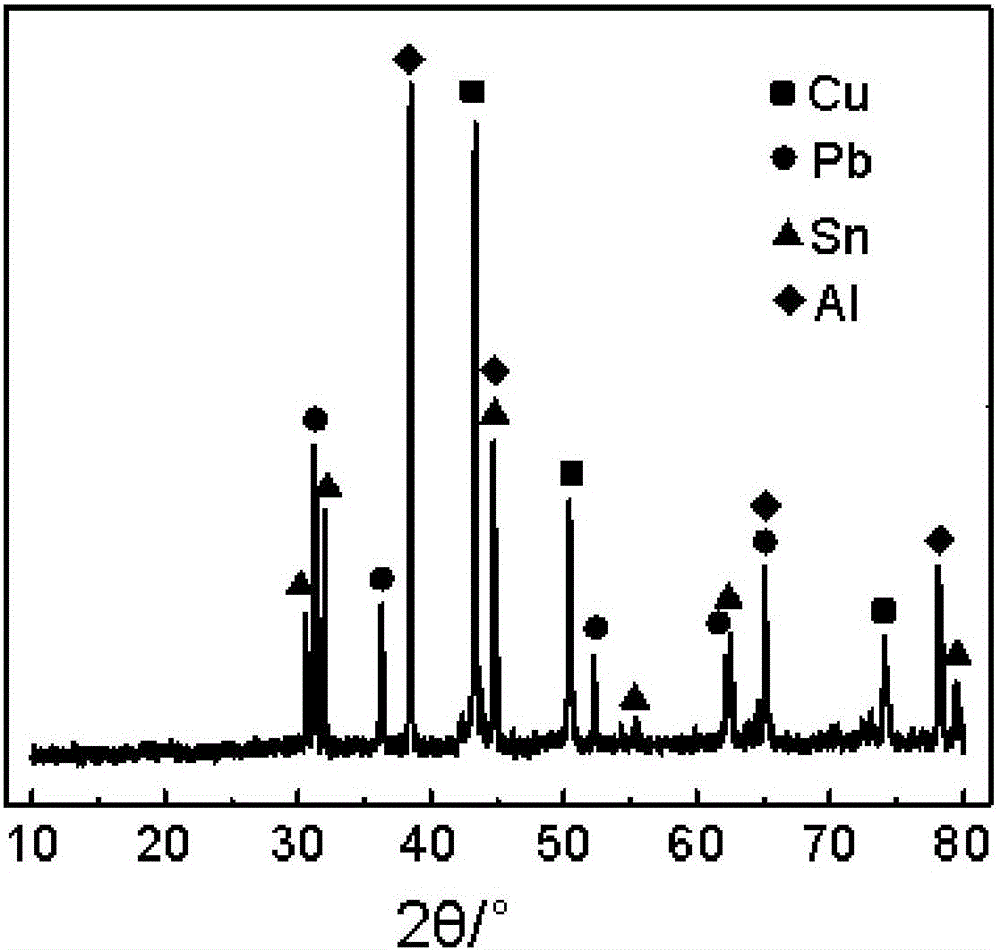

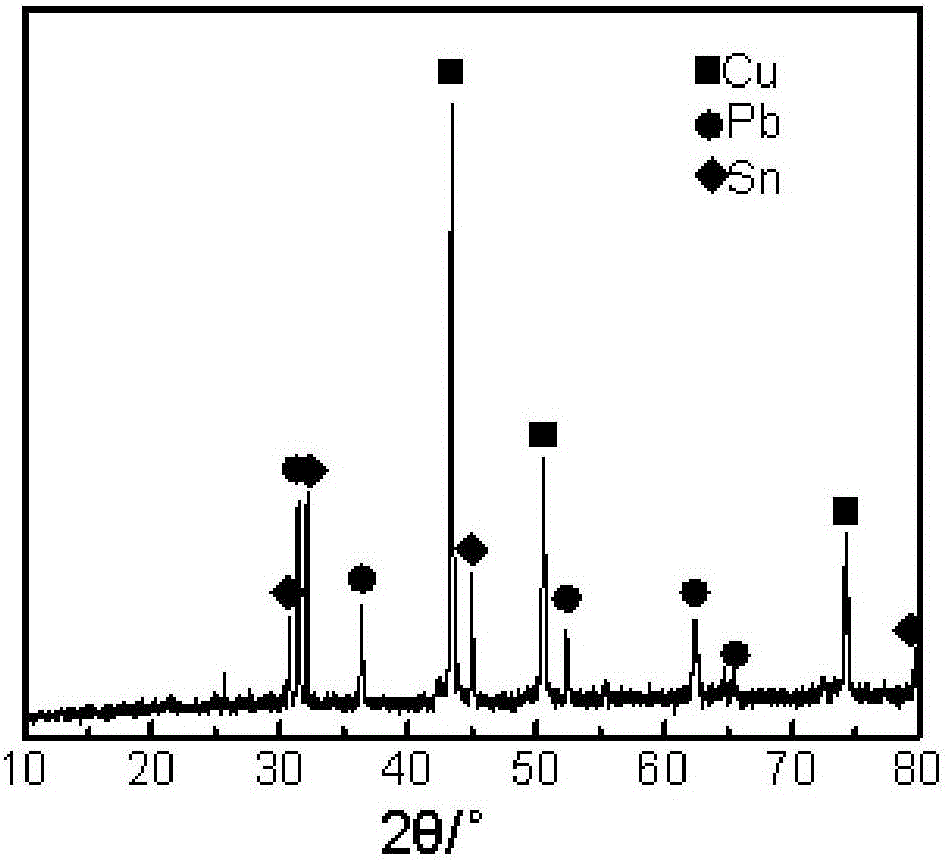

[0038] (1) Low-alkali leaching: Take 500g of waste circuit board polymetallic powder, add NaOH solution with a concentration of 2mol / L for leaching (the liquid-solid ratio of NaOH solution to polymetallic powder is 10:1), and the leaching temperature is 50°C Stirring and leaching for 30 minutes, wherein the stirring power is 300r / min, and filtering after stirring and leaching to obtain low-alkali leaching residue and low-alkali leaching solution. Copper, lead, tin and precious metals enter the low-alkali leaching slag (the XRD pattern is shown in image 3shown); aluminum and zinc enter the low-alkali leaching solution, and the leaching rates are 98.31% and 97.14% respectively. Add NaOH solution to the low-alkali leaching solution and return to the leaching step for recycling. After the valuabl...

Embodiment 2

[0041] A method for separating amphoteric metals in waste circuit boards of the present invention, its process flow chart is as follows figure 1 shown, including the following steps:

[0042] (1) Low-alkali leaching: Take 500g of waste circuit board polymetallic powder, add NaOH solution with a concentration of 1mol / L for leaching (the liquid-solid ratio of NaOH solution to polymetallic powder is 20:1), and the leaching temperature is 60°C. Stirring and leaching for 90 minutes, wherein the stirring power is 300r / min, and filtering after stirring and leaching to obtain low-alkali leaching residue and low-alkali leaching solution. Copper, lead, tin and precious metals enter the low-alkali leaching slag; aluminum and zinc enter the low-alkali leaching solution, and the leaching rates are 92.36% and 91.52%, respectively. Add NaOH solution to the low-alkali leaching solution and return to the leaching step for recycling. After the valuable metals are enriched to a certain extent, ...

Embodiment 3

[0045] A method for separating amphoteric metals in waste circuit boards of the present invention, its process flow chart is as follows figure 1 shown, including the following steps:

[0046] (1) Low-alkali leaching: Take 500g of waste circuit board polymetallic powder, add KOH solution with a concentration of 2mol / L for leaching (the liquid-solid ratio of KOH solution to polymetallic powder is 8:1), and the leaching temperature is 30°C. Stirring and leaching for 60 minutes, wherein the stirring power is 300r / min, and filtering after stirring and leaching to obtain low-alkali leaching residue and low-alkali leaching solution. Copper, lead, tin and precious metals enter the low-alkali leaching slag; aluminum and zinc enter the low-alkali leaching solution, and the leaching rates are 95.62% and 92.31%, respectively. Add KOH solution to the low-alkali leaching solution and return to the leaching step for recycling. After the valuable metals are enriched to a certain extent, alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com