Compound flame-retardant polystyrene granules and method for preparing same

A technology of polystyrene particles and polystyrene, which is applied in the field of new materials, can solve the problems of large waste water pollution in the production process, unsatisfactory graphite dispersion, and low production efficiency, and achieve diversified formulas, space saving, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

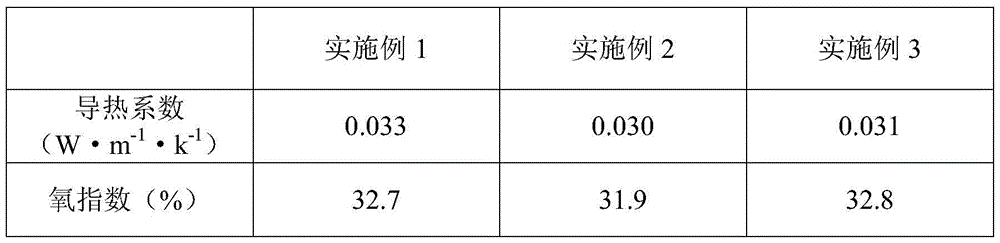

Embodiment 1

[0031] (1) Raw materials: select the polystyrene raw material with a melt index range of 5.05g / 10min. The polystyrene is a model of 158K polystyrene produced by Yangzi BASF Company. The graphite masterbatch is 600 mesh natural flake graphite, which is flame retardant The agent is hexabromododecane, and the physical foaming agent is pentane;

[0032] (2) Through the weightless multi-component feeding system, the feeding amount of each component is precisely controlled, and according to the predetermined production formula, the feeding amount of polystyrene resin is set to 81 parts by weight, and the amount of flame retardant is 5 parts by weight, graphite masterbatch is 7 parts by weight.

[0033] (3) Set the working temperature of each part of the extruder system: the barrel temperature is 180°C, 180°C, 175°C, 175°C, 170°C, 165°C, set the temperature of the connecting section between the extruder and the heat exchanger 160°C, set the heat exchanger temperature to 140°C;

[0...

Embodiment 2

[0040] (1) Raw material preparation: select the polystyrene of HIPS6075 model produced by Hong Kong Dow, the graphite masterbatch is 800 mesh natural flake graphite, the flame retardant is hexabromododecane, and the physical foaming agent adopts butane;

[0041] (2) Through the loss-in-weight multi-component feeding system, accurately control the feeding amount of each component, according to the predetermined production formula, set the amount of polystyrene resin to 100 parts by weight, and the amount of flame retardant to 3 Parts by weight, the amount of graphite masterbatch is 10 parts by weight;

[0042] (3) Set the working temperature of each part of the extruder system: the barrel temperature is 180°C, 180°C, 175°C, 175°C, 170°C, 165°C, set the temperature of the connecting section between the extruder and the heat exchanger 160°C, set the heat exchanger temperature to 140°C;

[0043] (4) Adjust the pressure of the extruder system, then start to inject 5 parts by weigh...

Embodiment 3

[0046] (1) Prepare materials: select the polystyrene of HIPS6075 model produced by Hong Kong Dow, the graphite masterbatch is 700 mesh natural flake graphite, the flame retardant is hexabromododecane, and the physical foaming agent adopts the mixture of carbon dioxide and nitrogen;

[0047] (2) Through the weightless multi-component feeding system, the feeding amount of each component is precisely controlled, and according to the predetermined production formula, the amount of polystyrene resin is set to 70 parts by weight, and the amount of flame retardant is 70 parts by weight. Parts by weight, the amount of graphite masterbatch is 5 parts by weight;

[0048](3) Set the working temperature of each part of the extruder system: the barrel temperature is 180°C, 180°C, 175°C, 175°C, 170°C, 165°C, set the temperature of the connecting section between the extruder and the heat exchanger 160°C, set the heat exchanger temperature to 140°C;

[0049] (4) Adjust the pressure of the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com