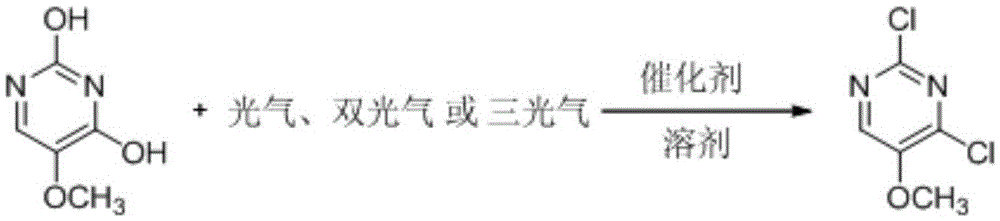

Preparation method of 2, 4-dichloro-5-methoxy pyrimidine

A technology of methoxypyrimidine and dihydroxy, which is applied in the field of preparation of 2,4-dichloro-5-methoxypyrimidine, can solve the problems of large amount of phosphorus oxychloride, difficult to handle, unfavorable for green production, etc. Achieve the effects of reducing the generation of phosphorus-containing wastewater, small heat release, and simplified post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Put 142.1g (1.0mol) of 2,4-dihydroxy-5-methoxypyrimidine, 5.1g (5mol%) of triethylamine and 200mL of acetonitrile into a thermometer, reflux condenser, dropping funnel and mechanical stirring In a 1000mL three-necked flask, slowly raise the temperature to 80°C and stir under reflux for 30 minutes. Then start slowly feeding phosgene, keep the feeding speed at 2 g / min, the feeding amount of phosgene is 4 times of the molar amount of 2,4-dihydroxy-5-methoxypyrimidine, and carry out the reflux reaction for 20 hours. After the reaction is finished, stop feeding phosgene, feed nitrogen after the temperature is lowered to room temperature to remove residual phosgene in the system. Then, the solid was removed by filtration under reduced pressure, 100 mL of water was added to the filtrate and stirred for 30 minutes, and then the aqueous phase was removed by liquid separation. The aqueous phase was extracted with 100 mL of acetonitrile, and the two organic phases were combined, ...

Embodiment 2

[0019] Put 142.1g (1.0mol) of 2,4-dihydroxy-5-methoxypyrimidine, 7.4g (10mol%) of N,N-dimethylformamide and 200mL of ethylene glycol dimethyl ether into a thermometer equipped with In a reflux condenser, a dropping funnel, and a mechanically stirred 1000 mL three-necked flask, slowly raise the temperature to 100° C. and reflux and stir for 30 minutes. Then start slowly feeding phosgene, keep the feeding speed at 2 g / min, the feeding amount of phosgene is 4 times of the molar amount of 2,4-dihydroxy-5-methoxypyrimidine, and carry out the reflux reaction for 20 hours. After the reaction is finished, stop feeding phosgene, feed nitrogen after the temperature is lowered to room temperature to remove residual phosgene in the system. Then, the solid was removed by filtration under reduced pressure, 100 mL of water was added to the filtrate and stirred for 30 minutes, and then the aqueous phase was removed by liquid separation. The aqueous phase was extracted with 100 mL of acetonit...

Embodiment 3

[0021] 142.1g (1.0mol) of 2,4-dihydroxy-5-methoxypyrimidine, 24.2g (20mol%) of N,N-dimethylaniline, 989.2g (5.0mol) of diphosgene and 1,4- 300 mL of dioxane was put into a 1000 mL three-necked flask equipped with a thermometer, a reflux condenser, a dropping funnel and mechanical stirring, and the temperature was slowly raised to 110° C. for 20 hours under reflux and stirring. After the reaction, the temperature was lowered to room temperature and nitrogen gas was introduced to remove residual phosgene in the system. Then, the solid was removed by filtration under reduced pressure, 100 mL of water was added to the filtrate and stirred for 30 minutes, and then the aqueous phase was removed by liquid separation. The aqueous phase was extracted with 100 mL of acetonitrile, and the two organic phases were combined, dried over anhydrous sodium sulfate, and the solvent was recovered under reduced pressure to obtain an off-white solid with a purity of 98.3% and a yield of 82%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com