A kind of low-density ammonium oil explosives and its preparation method and application

An ammonium oil explosive and low-density technology, applied in explosive processing equipment, explosives, explosive composite components, etc., can solve the problem of not being able to meet the requirements of large-scale use in large-scale open-pit coal mines, and increase the probability that explosive vehicles will crush blastholes and detonating equipment , It is not conducive to improving the quality of blasting, etc., to achieve the effect of improving the blasting effect, low comprehensive cost of blasting, and beneficial to the rate of lump coal blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Raw material composition of low density ammonium oil explosives:

[0082] Porous granular ammonium nitrate 86 tons

[0083] Perlite particles 9 tons

[0084] Diesel 5 tons.

[0085] Preparation:

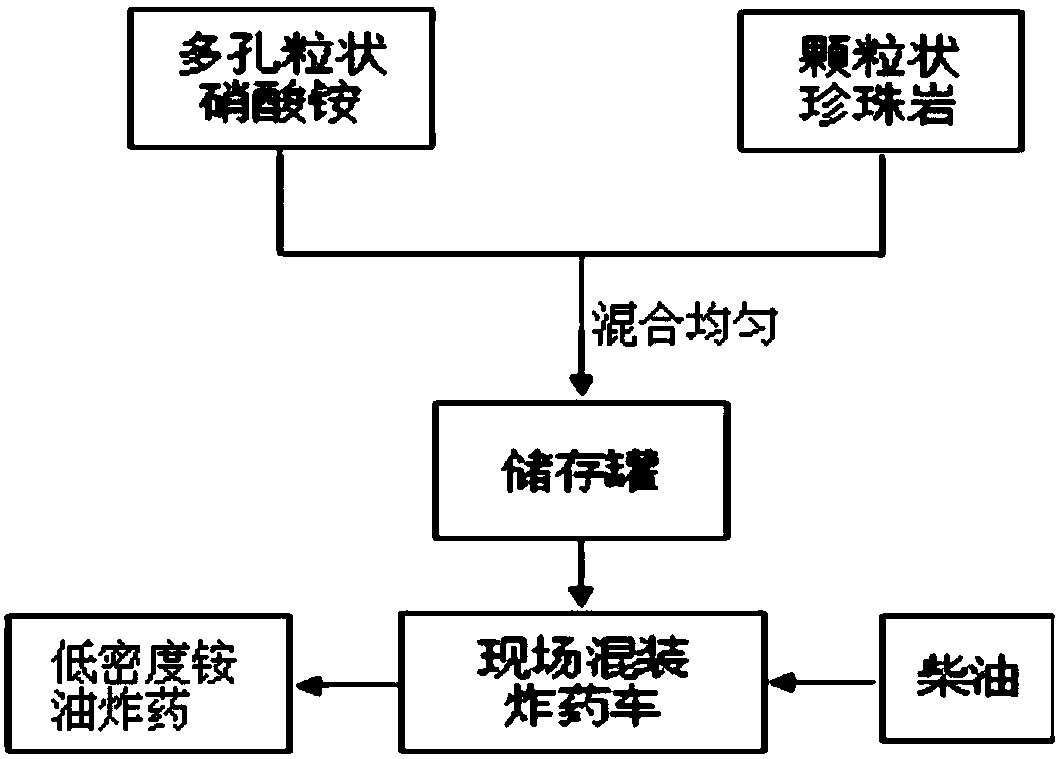

[0086] (1) prepare porous granular ammonium nitrate, perlite particles and diesel oil by said weight;

[0087] (2) the porous granular ammonium nitrate and perlite particles are mixed uniformly to obtain a mixture;

[0088] (3) said mixture and diesel oil are added in the corresponding hopper of on-the-spot mixing explosives vehicle respectively;

[0089] (4) Enter the production interface by operating the production operation control system of the on-site mixed explosive vehicle, select the explosive type and production volume, start production, and mix the mixture and diesel oil while transporting to obtain the low-density ammonium oil explosives.

[0090] Then carry out on-site quality control to the prepared low-density ammonium oil explosives: take out part of the l...

Embodiment 2

[0095] Raw material composition of low density ammonium oil explosives:

[0096] Porous granular ammonium nitrate 90.7 tons

[0097] Perlite particles 4.0 tons

[0098] Diesel 5.3 tons.

[0099] Preparation:

[0100] (1) prepare porous granular ammonium nitrate, perlite particles and diesel oil by said weight;

[0101] (2) Mix the porous granular ammonium nitrate, perlite particles and diesel oil evenly to obtain the low-density ammonium oil explosive.

[0102] Then carry out on-site quality control to the prepared low-density ammonium oil explosives: take out part of the low-density ammonium oil explosives, and carry out quality inspection on its density and uniformity, and the measured density is 0.69g / cm 3 , theoretical density 0.65-0.7g / cm 3 , the two are consistent, and the visual uniformity is good.

[0103] The wave impedance of the prepared low-density ammonium fuel explosive is 1.68×10 6 kg / m 2 s, detonation velocity is 2435m / s, no detonator sensitivity, good ...

Embodiment 3

[0106] Raw material composition of low density ammonium oil explosives:

[0107] Porous granular ammonium nitrate 86.7 tons

[0108] Perlite granules 8.3 tons

[0109] Diesel 5.0 tons.

[0110]Preparation:

[0111] (1) prepare porous granular ammonium nitrate, perlite particles and diesel oil by said weight;

[0112] (2) the porous granular ammonium nitrate and perlite particles are mixed uniformly to obtain a mixture;

[0113] (3) said mixture and diesel oil are added in the corresponding hopper of on-the-spot mixing explosives vehicle respectively;

[0114] (4) Enter the production interface by operating the production operation control system of the on-site mixed explosive vehicle, select the explosive type and production volume, start production, and mix the mixture and diesel oil while transporting to obtain the low-density ammonium oil explosives.

[0115] Then carry out on-site quality control to the prepared low-density ammonium oil explosives: take out part of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| oxidation stability | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com