Graphene self-supporting material subjected to ion-induced assembly and preparation method thereof

A technology of ion induction and graphene, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of impractical, time-consuming, preparation of graphene materials, etc., to achieve improved conductivity, easy availability of raw materials, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

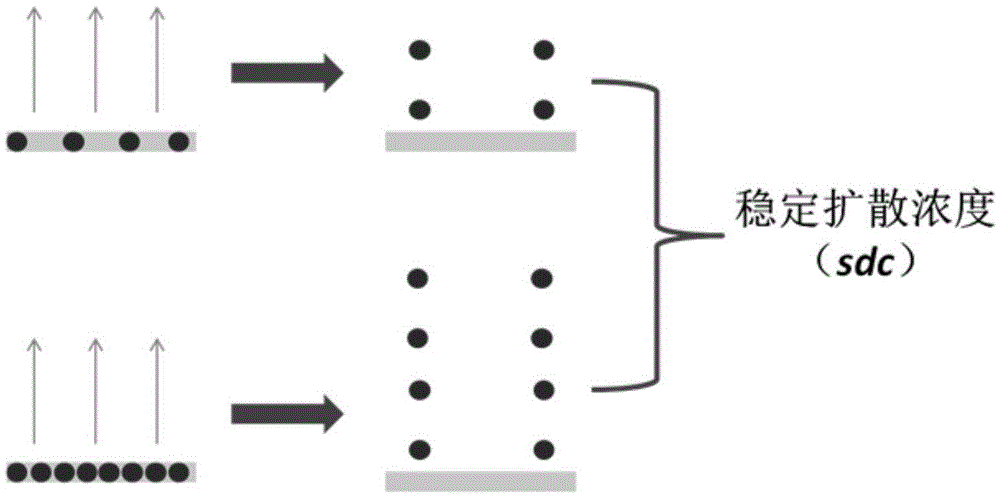

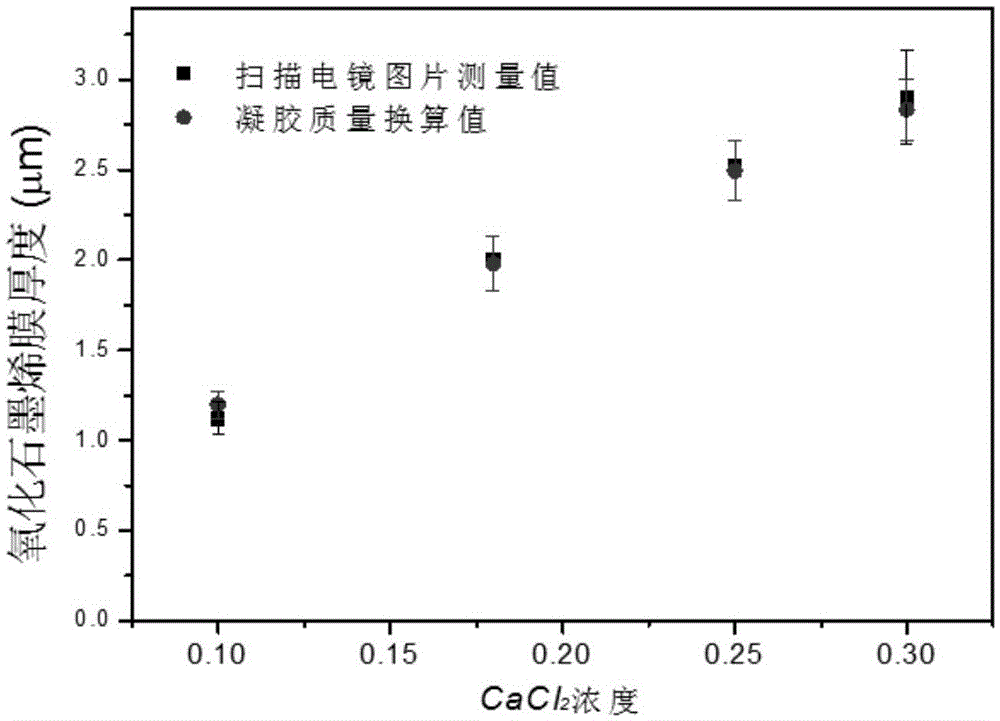

[0031] A kind of ion-induced assembly graphene self-supporting material and the steps of preparation method thereof are as follows:

[0032] 1) Add 1 part by weight of graphene oxide, 20-500 parts by weight of solvent, 0.1-1 part by weight of 25% mass fraction ammonia water in the container, and stir it evenly to obtain a graphene oxide dispersion;

[0033] 2) Adsorb the ionic cross-linking agent of 0-saturation concentration on the substrate;

[0034] 3) immerse the above-mentioned substrate in the graphene oxide dispersion liquid, and stay for 1 second to 30 minutes;

[0035] 4) Slowly propose the substrate adhered with graphene oxide gel;

[0036] 5) drying or lyophilizing the above-mentioned gel, removing the substrate, and obtaining the graphene oxide self-supporting material;

[0037] 6) Carrying out chemical reduction or thermal reduction to the above materials to obtain graphene self-supporting materials.

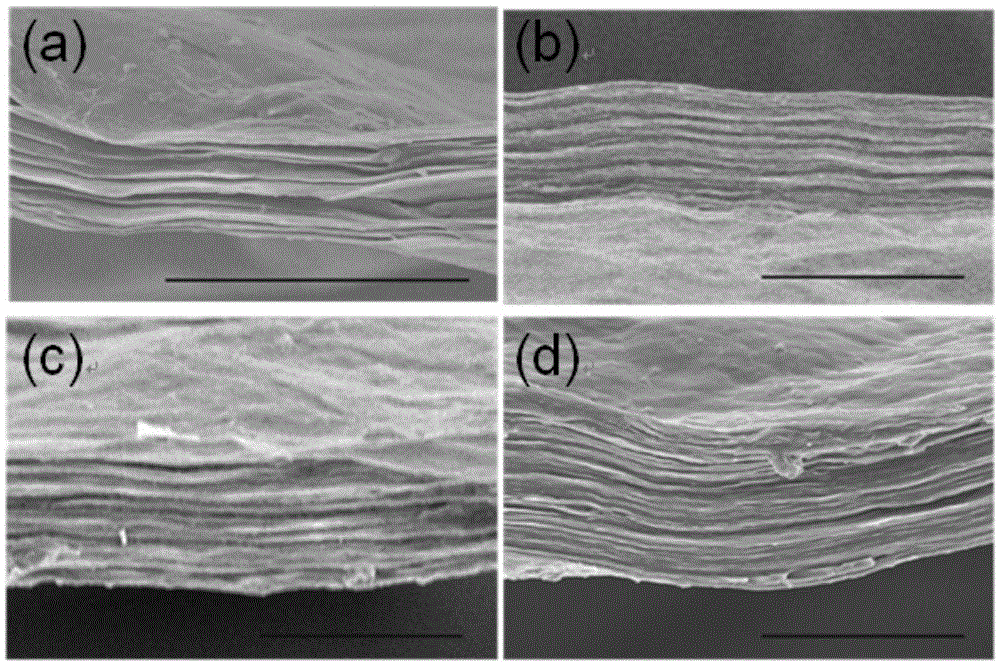

Embodiment 1

[0040] 1) Add 1 part by weight of graphene oxide, 500 parts by weight of solvent, 0.1-1 part by weight of ammonia water with a mass fraction of 25%, and stir it evenly to obtain a graphene oxide dispersion;

[0041] 2) Adhering 0.05M calcium chloride solution on the copper wire;

[0042] 3) immerse the above-mentioned copper wire in the graphene oxide dispersion liquid, and stay for 20 seconds;

[0043] 4) Slowly propose the copper wire adhered with graphene oxide gel;

[0044] 5) Dry the above gel, use FeCl 3 The solution removes the substrate to obtain graphene oxide tubular fibers;

[0045] 6) the above-mentioned material is reduced with hydroiodic acid to obtain a graphene tube, such as Figure 4 shown. The graphene tube can be used as a chemical-resistant and high-temperature-resistant delivery pipeline.

Embodiment 2

[0047] 1) Add 1 part by weight of graphene oxide, 500 parts by weight of solvent, and 0.1-1 part by weight of ammonia water in the container, and stir it evenly to obtain a graphene oxide dispersion;

[0048] 2) Adhering 0.05M calcium chloride solution on the inflated balloon;

[0049] 3) Submerge the above-mentioned balloon in the graphene oxide dispersion and stay for 20 seconds;

[0050] 4) propose a balloon adhered with graphene oxide gel;

[0051] 5) The above-mentioned gel is dried, and the balloon is deflated so that it is detached from the graphene oxide material to obtain a graphene oxide bowl-shaped container;

[0052] 6) After carrying out chemical reduction and heat treatment at 3000 degrees centigrade to the above-mentioned materials with hydroiodic acid, a graphene bowl-shaped container is obtained. like Figure 5 shown.

[0053] It can be used as a chemical-resistant and high-temperature-resistant container, with a temperature resistance of 690 degrees Celsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com