Cylindrical material filling mechanism

A filling mechanism and cylindrical technology, which is applied in the field of workpiece conveying and filling mechanism to achieve the effect of reducing failure rate, improving storage mode and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

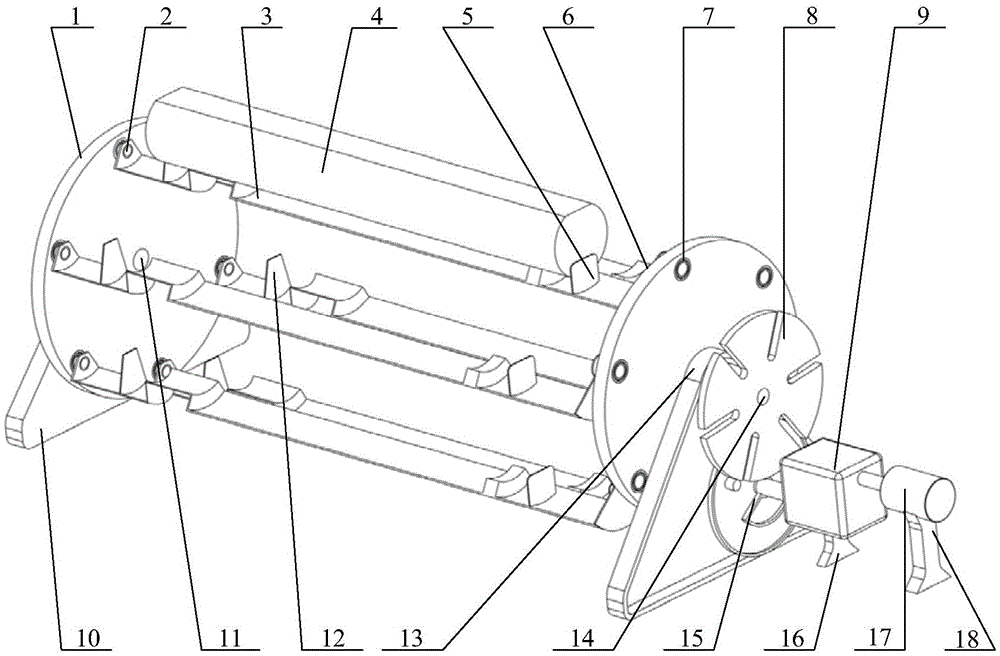

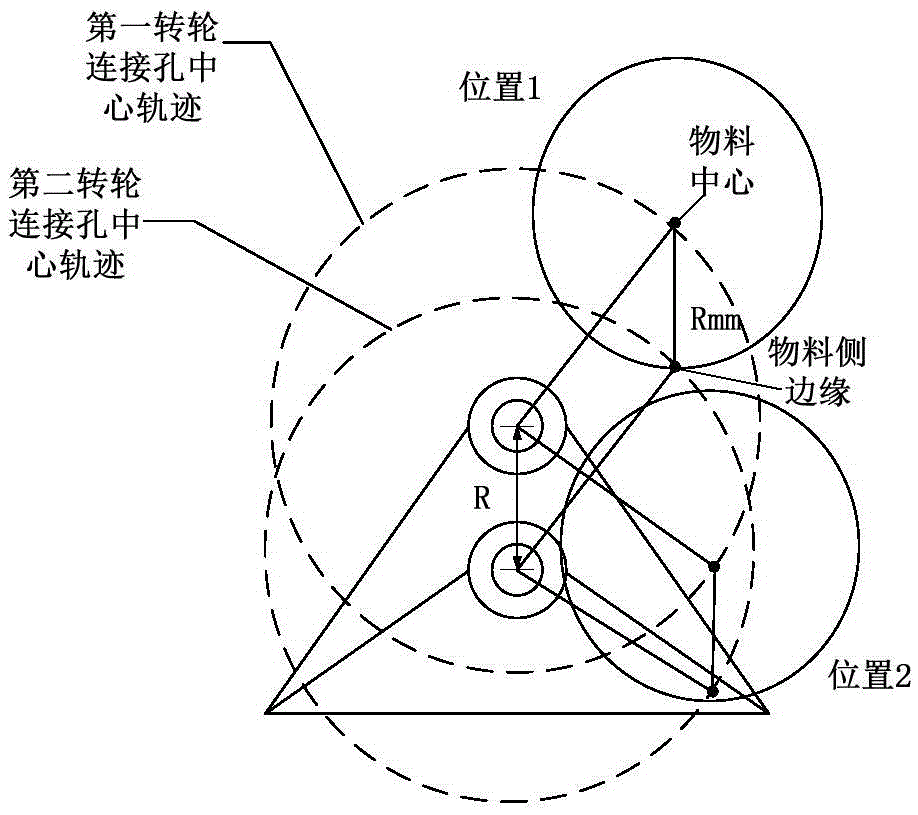

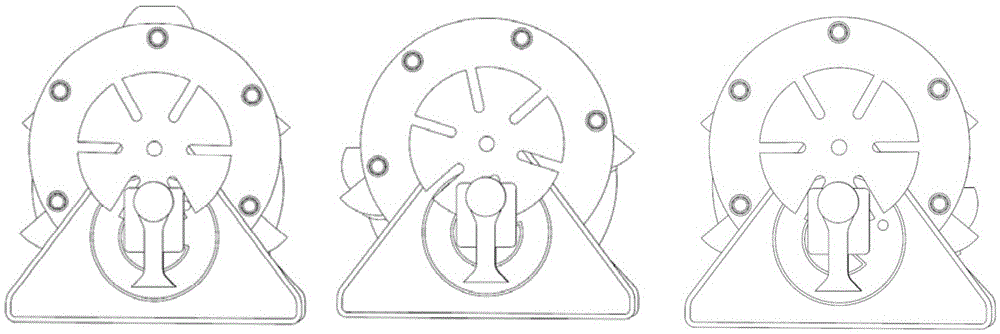

[0013] The following is attached Figure 1-3 The technical solution of the present invention is described in detail.

[0014] Such as Figure 1-3 As shown, the present invention provides a cylindrical material loading mechanism, comprising a first runner 1, a material bottom support connecting pin 2, a material bottom support 3, a cylindrical material 4, a material bottom edge baffle 5, a second runner 6. Bearing 7, sheave 8, deceleration device 9, first bracket 10, runner connecting pin 11, cylindrical material front end baffle 12, second bracket 13, sheave connecting pin 14, dial 15, deceleration device support Frame 16, motor 17, motor support frame 18.

[0015] Wherein: the first runner 1 is connected on the first bracket 10 through the runner connecting pin 11, and can rotate around the runner connecting pin 11, and the second runner 6 is connected on the second bracket 13 through the runner connecting pin 11 , and can rotate around the connecting pin 11 of the runner,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com