Carbon fiber shelter

A carbon fiber and shelter technology, applied in the field of shelters made of non-metallic materials, can solve the problems of restricting the use of the shelter and the weight of the cabin, and achieve the effect of reducing weight, high stiffness and strength, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

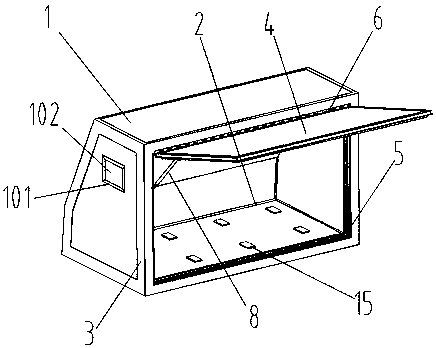

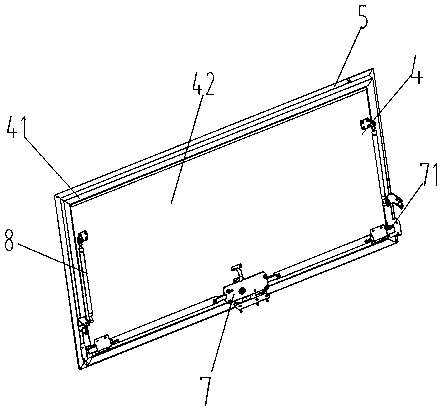

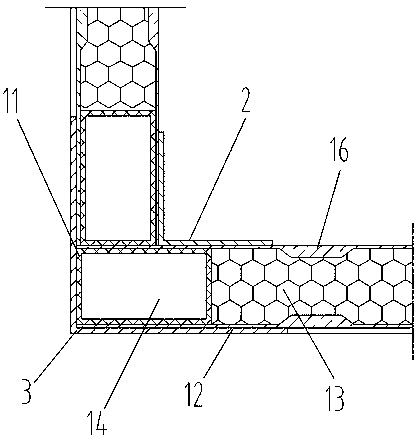

[0017] Such as Figure 1 ~ Figure 3 Shown, the present invention comprises 7 carbon fiber composite panels 1, 15 carbon fiber inner beading bars 2 and 15 carbon fiber outer corner strips 3 and carbon fiber doors 4, and 7 carbon fiber composite panels 1 as wall panels are assembled into a heptahedral cabin body ( Wherein one side is carbon fiber door 4). At the joints of the 7 carbon fiber composite panels 1, there are externally equipped with carbon fiber outer corner strips 2, lined with carbon fiber inner beading strips 3, and the 7 carbon fiber composite panels 1 pass through 15 carbon fiber outer cladding strips 3 and 15 carbon fiber inner beading strips 2 The cabin body is fixed by glue riveting, and the longitudinal vertical outer surface of the cabin body is provided with a carbon fiber door 4 .

[0018] The carbon fiber composite panel 1 includes a carbon fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com