Glue binding assembly universal for ethylene vinyl acetate (EVA) glue and polyurethane rubber (PUR) glue

A technology for glue-packing machines and assemblies, applied in the field of structural parts, can solve the problems of large mechanical impact, inability to use interchangeably, and difficulty in cleaning waste glue and maintaining parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

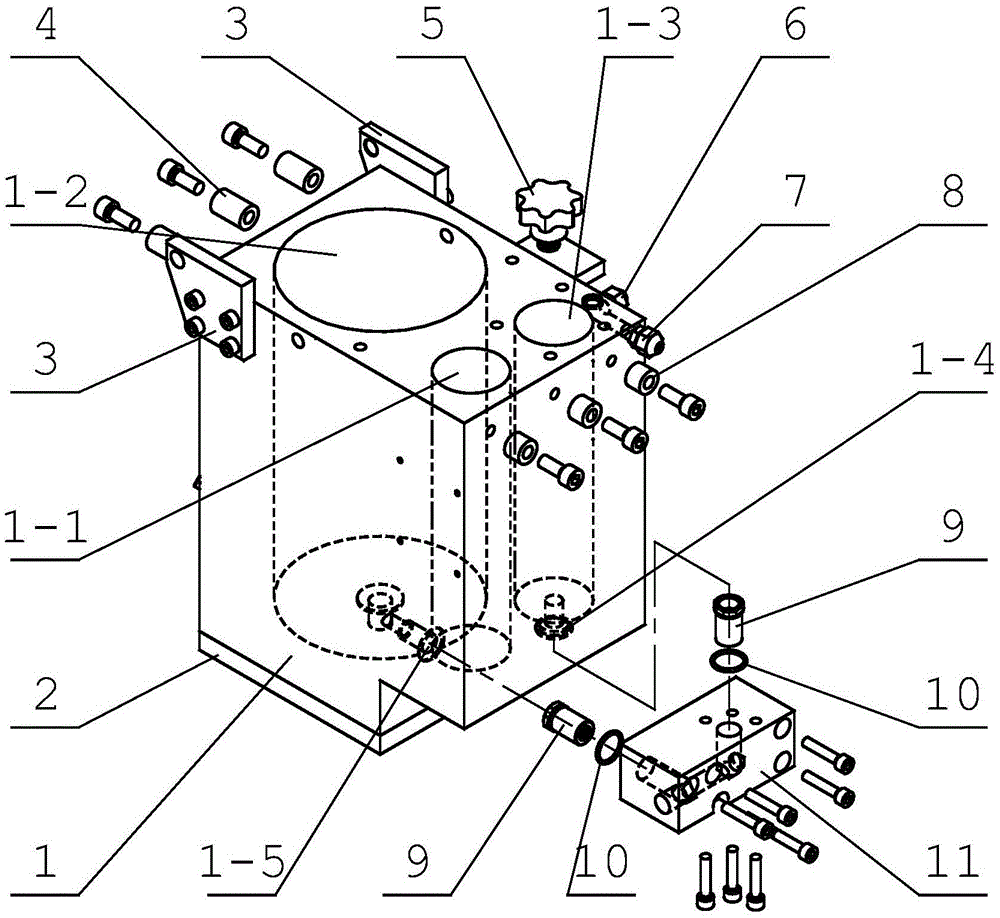

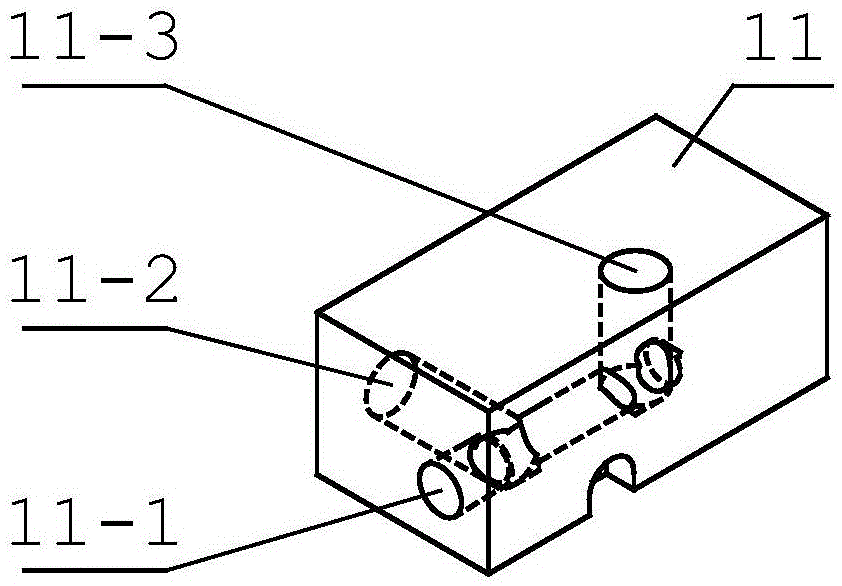

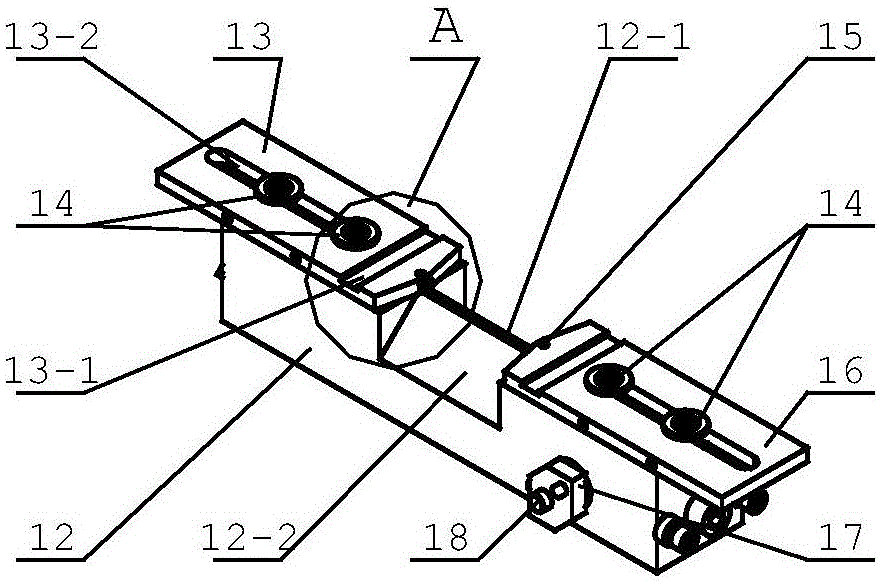

Embodiment 1

[0046] EVA glue and PUR glue universal binding machine assembly has a bracket seat 42, a milling cutter 67 is installed in the milling cutter table body 63 on the left part above the bracket seat, and a guide is fixed on both sides of the front and rear parts of the milling cutter table body. Block 65, front cover plate 62 is installed between the two guide blocks of the front portion, and rear cover plate 68 is installed between the two guide blocks of the rear portion, front guide wheel 66 is connected on the front cover plate, and the rear cover plate is connected with Rear guide wheel 69, respectively is connected with extension spring 64 between described front and back cover plate and milling cutter table body, is connected with wallboard support 44 on the bracket seat, and pivoting axle sleeve 43 is installed on the wallboard support, and this pivoting axle sleeve The upper pivot is connected with a front wallboard 47 and a rear wallboard 45, and the corresponding place ...

Embodiment 2

[0061] The difference from the above example is that this example uses a three-way pipe to replace the connecting block of the above example. There is a three-way pipe under the rubber storage cylinder. One end is in communication with the glue outlet of the right cylinder, and the other end of the three-way pipe is connected with the glue outlet pipe 40 . Other constructions are the same as the above example.

Embodiment 3

[0063] see Figure 13 The difference from Example 1 is that there is no connection block in this example, and the corresponding large cylinder glue outlet 73 and the right cylinder glue outlet 74 are each connected with a rubber outlet pipe, which are respectively connected to the connecting flange 23 and the glue spray pipeline. Check valve 24. Other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com