A die forging production method of hydraulic support connector of coal machine

The technology of a hydraulic support and a production method is applied in the field of forging using die forging to process hydraulic support connectors, which can solve the problems of low production efficiency, low labor intensity, and high processing difficulty, and achieve high production efficiency, low labor intensity, and good surface quality. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A die forging production method of a coal machine hydraulic support connector in this embodiment includes the following steps:

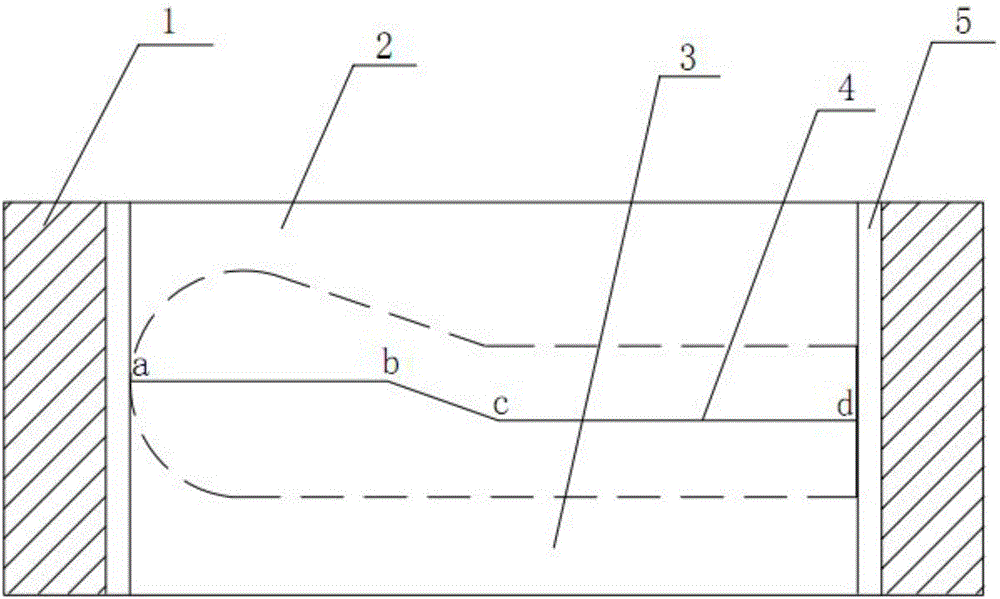

[0027] 1) Make a mold

[0028] Design and manufacture the die forging die according to the drawing size requirements of the hydraulic support connector. The die forging die takes the maximum projection surface of the connector as the parting surface, the upper and lower die chambers are both concave dies, and the die forging die is divided by a broken line. For the parting face The oblique parting surface formed by the trend should be as gentle as possible to reduce the drop, so that the flange of the mold is lowered and the depth of the cavity is reduced, thereby improving the strength and life of the mold; the upper module and the lower module of the forging mold are clamped in the mold sleeve at one time Molding, the closed height of the mold is equal to the sum of the height of the upper module and the lower module plus 0.3-0.5mm buffer to...

Embodiment 2

[0043] A die forging production method of a coal machine hydraulic support connector in this embodiment includes the following steps:

[0044] 1) Make a mold

[0045] Design and manufacture the die forging die according to the drawing size requirements of the hydraulic support connector. The die forging die takes the maximum projection surface of the connector as the parting surface, the upper and lower die chambers are both concave dies, and the die forging die is divided by a broken line. For the parting face The oblique parting surface formed by the trend should be as gentle as possible to reduce the drop, so that the flange of the mold is lowered and the depth of the cavity is reduced, thereby improving the strength and life of the mold; the upper module and the lower module of the forging mold are clamped in the mold sleeve at one time Molding, the closed height of the mold is equal to the sum of the height of the upper module and the lower module plus 0.3-0.5mm buffer to...

Embodiment 3

[0060] A die forging production method of a coal machine hydraulic support connector in this embodiment includes the following steps:

[0061] 1) Make a mold

[0062] Design and manufacture the die forging die according to the drawing size requirements of the hydraulic support connector. The die forging die takes the maximum projection surface of the connector as the parting surface, the upper and lower die chambers are both concave dies, and the die forging die is divided by a broken line. For the parting face The oblique parting surface formed by the trend should be as gentle as possible to reduce the drop, so that the flange of the mold is lowered and the depth of the cavity is reduced, thereby improving the strength and life of the mold; the upper module and the lower module of the forging mold are clamped in the mold sleeve at one time Molding, the closed height of the mold is equal to the sum of the height of the upper module and the lower module plus 0.3-0.5mm buffer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com