Magnesium-based hydrogen storage material of core-shell structure and preparation method of the magnesium-based hydrogen storage material

A technology of core-shell structure and hydrogen storage materials, applied in metal processing equipment, transportation and packaging, etc., can solve undiscovered problems, achieve the effects of improving hydrogen absorption and desorption performance, improving kinetic and thermodynamic performance, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention discloses a method for preparing a magnesium-based hydrogen storage material with a core-shell structure, the preparation method comprising the following steps:

[0030] Step 1, preparing a precursor solution of a certain concentration, and ultrasonically mixing it with a certain mass of magnesium particles to obtain a suspension of magnesium particles;

[0031] Step 2. Slowly add 95% ethanol solution dropwise to the suspension of the above-mentioned magnesium particles under the condition of vigorous stirring, and let it stand for 12 hours, and the titanium metal alkoxide undergoes hydrolysis reaction to form titanium hydroxide, which is coated on the surface of magnesium particles;

[0032] Step 3: Centrifuge and wash the suspension obtained in the above steps, and keep the obtained sample at 400° C. under vacuum conditions for 12 hours to obtain a magnesium-based hydrogen storage material with a core-shell structure coated with titanium oxide.

[0033] T...

Embodiment 1

[0039] (1) Prepare a 0.05 g / ml ethanol solution of tetrabutyl titanate, stir for 2 hours to make it evenly mixed;

[0040] (2) Weigh 0.2g of micro-nano magnesium particles, add it to 20ml of absolute ethanol, mix it into a suspension, and mix the 4ml tetrabutyl titanate ethanol solution prepared in (1) with the aforementioned solution at room temperature, Stir evenly and ultrasonically treat for 20 minutes;

[0041] (3) Under the condition of vigorous stirring, slowly drop 8 ml of 95% ethanol solution into the suspension of micro-nano magnesium particles, and let it stand for 12 hours;

[0042] (4) wash 3 times with absolute ethanol, vacuum dry, collect powder;

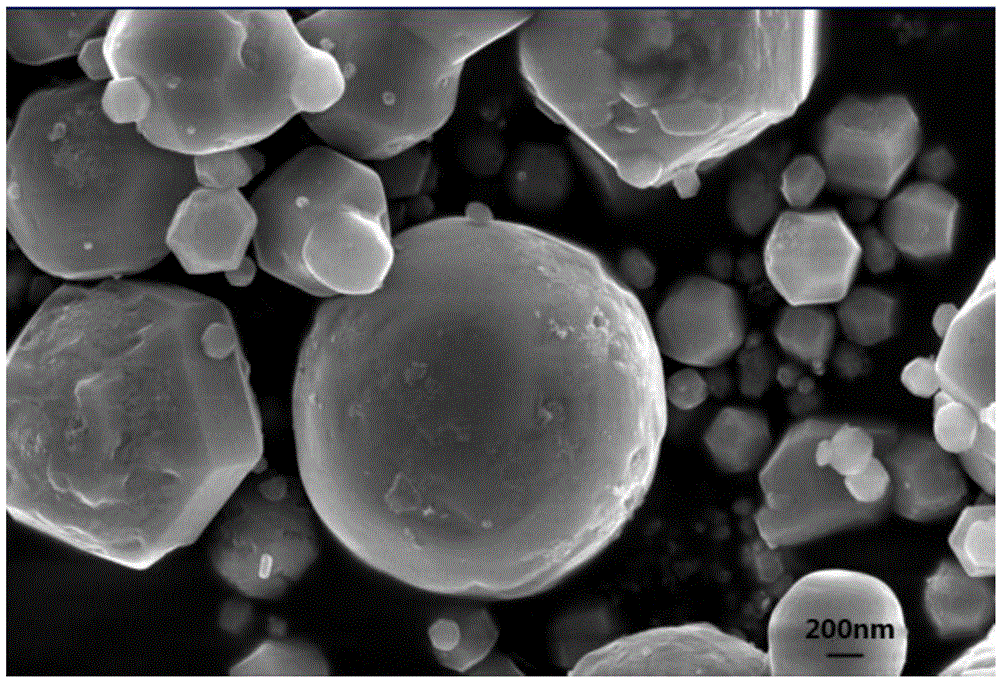

[0043] (5) Insulate the dried powder at 400°C and vacuum for 12 hours and slowly cool it to take out the powder sample, which is the magnesium particle material coated with titanium oxide, wherein the titanium oxide in the shell is TiO 2 , The thickness of the shell is about 30-60nm.

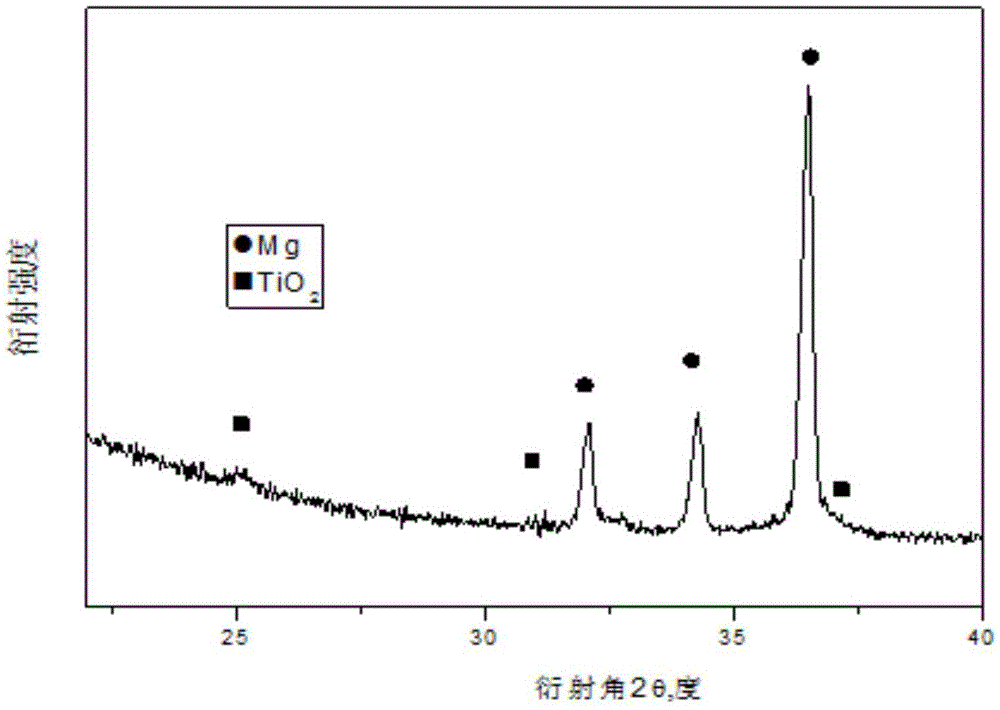

[0044] figure 1 MgTiO prepar...

Embodiment 2

[0046] (1) Prepare a 0.05 g / ml ethanol solution of tetrabutyl titanate, stir for 2 hours to make it evenly mixed;

[0047] (2) Weigh 0.2g of micro-nano magnesium particles, add it to 20ml of absolute ethanol, mix it into a suspension, and mix the 8ml tetrabutyl titanate ethanol solution prepared in (1) with the aforementioned solution at room temperature, Stir evenly and ultrasonically treat for 20 minutes;

[0048] (3) under the condition of vigorous stirring, slowly drop 16 ml of 95% ethanol solution into the suspension of micro-nano magnesium particles, and let it stand for 12 hours;

[0049] (4) wash 3 times with absolute ethanol, vacuum dry, collect powder;

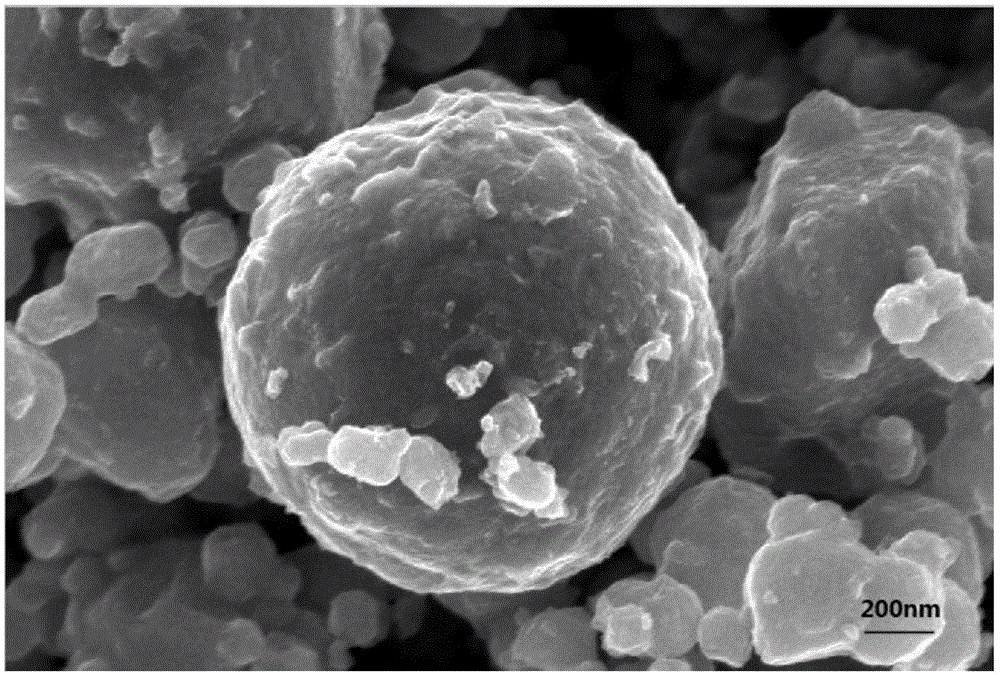

[0050] (5) Insulate the dried powder at 400°C and vacuum for 12 hours and slowly cool it to take out the powder sample, which is the magnesium particle material coated with titanium oxide, wherein the titanium oxide in the shell is TiO 2 , The thickness of the shell is about 60-100nm.

[0051] figure 2 MgTiO pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com