Boss molding process for pipe

A forming process and technology for pipe fittings, applied in the field of boss forming process of pipe fittings, can solve the problems of insufficient welding strength, high production cost, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

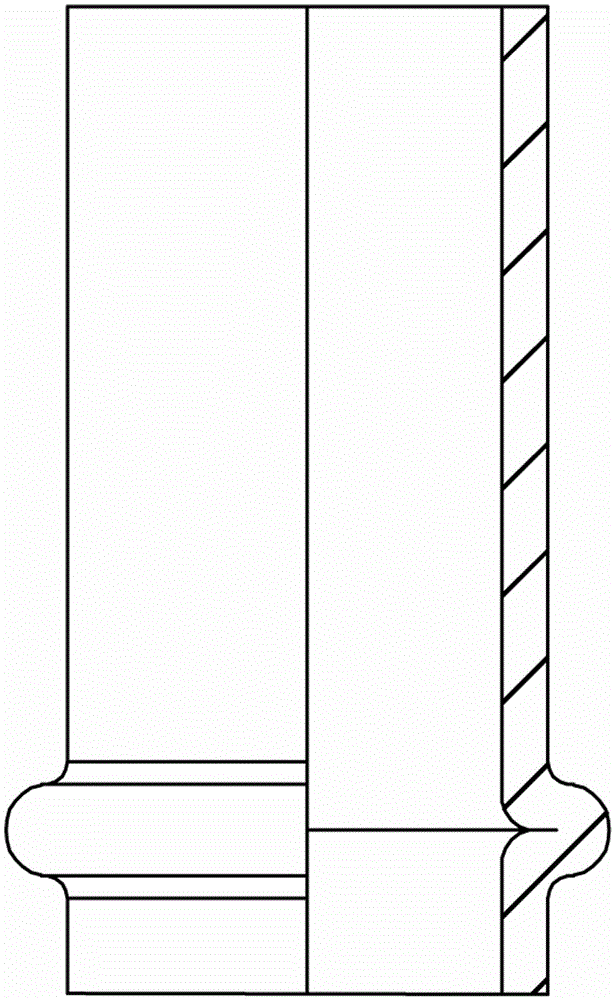

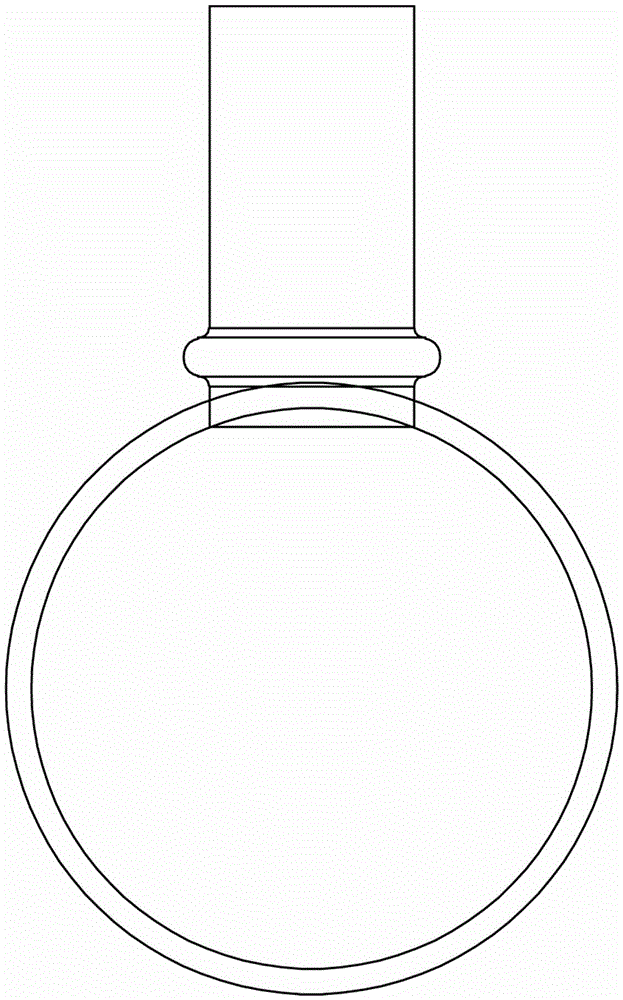

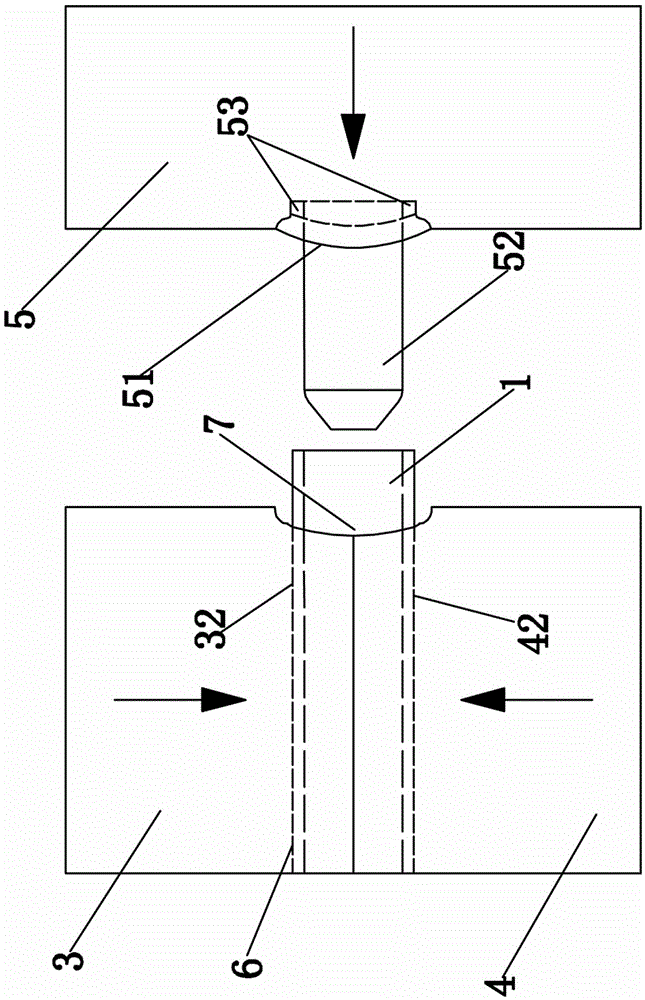

[0029] Embodiment one, such as Figure 3 to Figure 8 As shown, a boss forming device for pipe fittings includes an upper clamp 3, a lower clamp 4 and a stamping die 5, and the upper clamp 3 and the lower clamp 4 are respectively provided with an upper pinch groove 32 and a lower pinch groove 42, The ends of the upper clamping groove 32 and the lower clamping groove 42 are respectively provided with an upper half die 31 and a lower half die 41. After the upper clamp 3 and the lower clamp 4 are combined, the upper clamping groove 32 and the lower clamp 4 are assembled. The lower clamping groove 42 is assembled into a pipe cavity 6, and the lower half die 41 and the upper half die 31 are assembled into a tubular curved surface die 7, and the bottom of the tubular curved surface die 7 is connected with the pipe cavity. 6 connected.

[0030] Described stamping mold 5 is respectively provided with positioning pin 52 and curved surface punch 51 corresponding to tubular cavity 6 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com