Universal pulverizer

A universal pulverizer and pulverizing chamber technology, applied in grain processing and other directions, can solve the problems of wasting water resources, poor cooling effect, etc., and achieve the effect of good effect, comfortable and convenient working experience, and increased flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

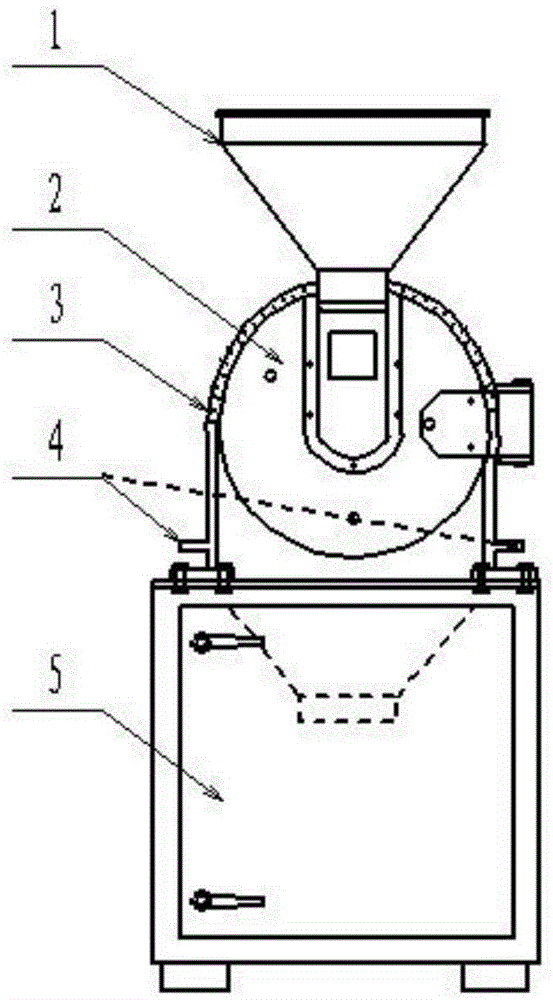

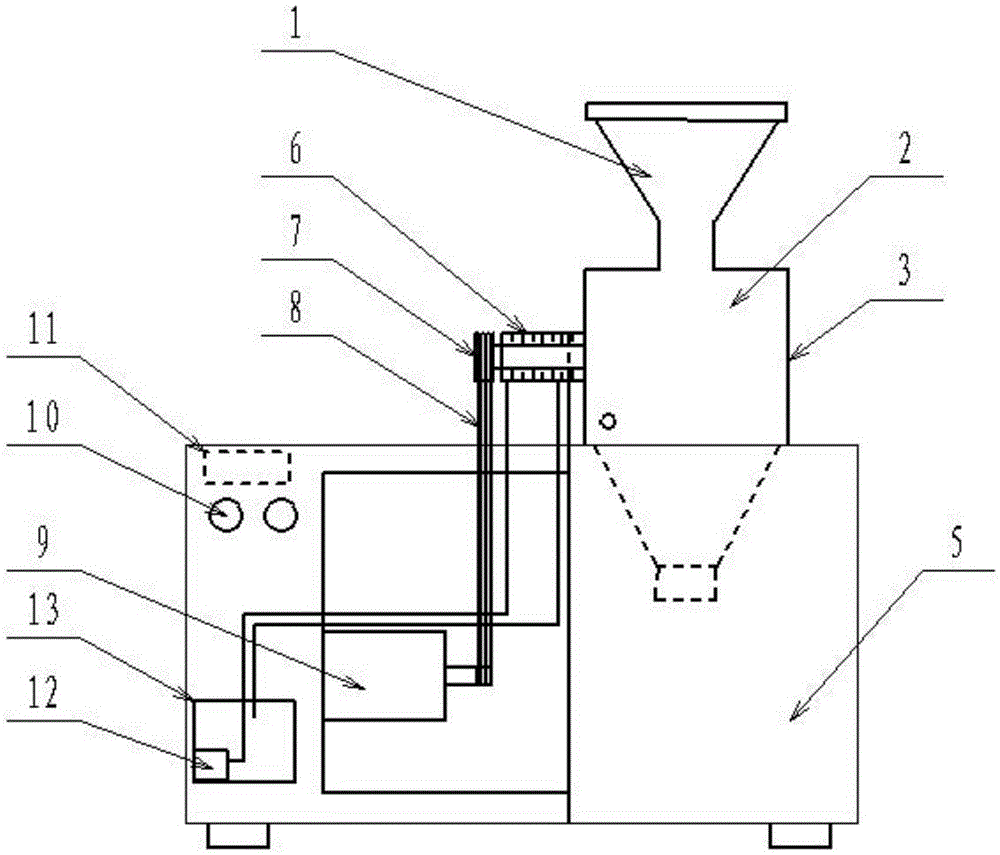

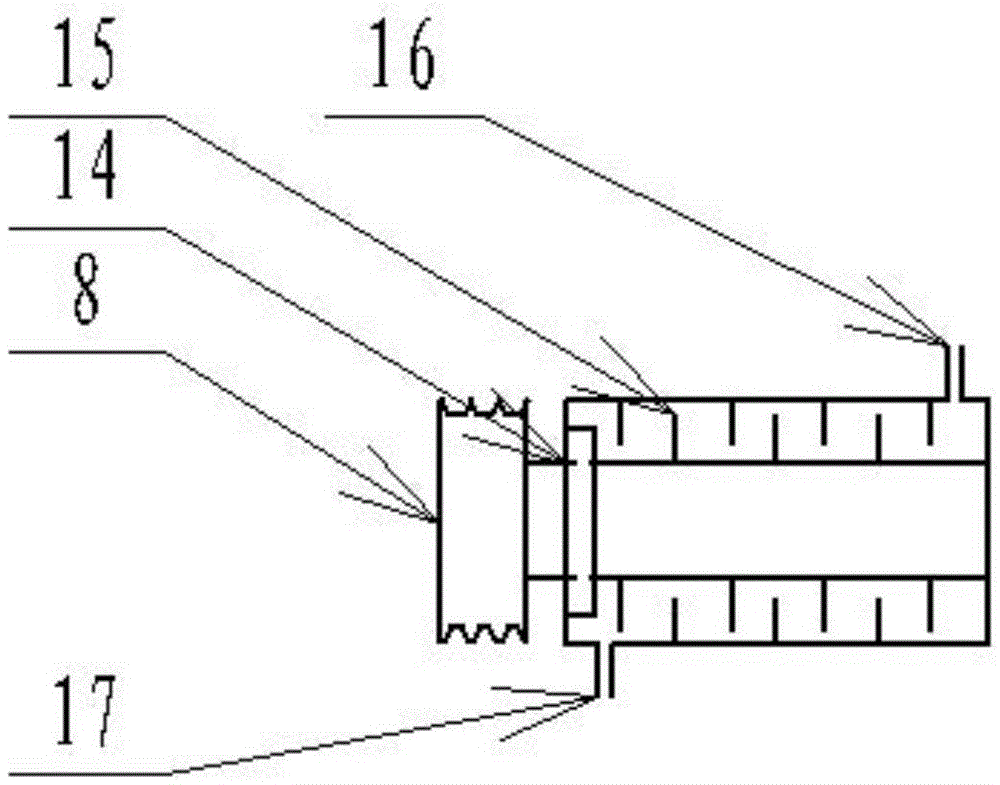

[0033] A universal pulverizer, such as figure 1 or 2, the grinder includes a hopper 1, a crushing chamber 2, a crushing chamber wall 3, a material collection box 5, a drive motor 9, a power switch 10, and a cooling cycle system; the cooling cycle system includes a transmission shaft cooling Device 6, coolant circulation pipeline, circulation pump 12, coolant circulation tank 13; transmission shaft cooling device 6 is a cavity structure, arranged outside the transmission shaft, and sleeved on the transmission shaft, with clearance fit, and connected to rotate The outer ring of the bearing 14, the liquid outlet 16 and the liquid inlet 17 of the transmission shaft cooling device 6 are respectively connected to the coolant circulation pipeline, and the other end of the coolant circulation pipeline connected to the liquid outlet 16 is arranged above the interior of the coolant circulation tank , the other end of the coolant circulation pipeline connected to the liquid inlet 17 is c...

Embodiment 2

[0036] A universal pulverizer, such as figure 1 or 2, the grinder includes a hopper 1, a crushing chamber 2, a crushing chamber wall 3, a material collection box 5, a drive motor 9, a power switch 10, and a cooling cycle system; the cooling cycle system includes a transmission shaft cooling Device 6, coolant circulation pipeline, circulation pump 12, coolant circulation tank 13; transmission shaft cooling device 6 is a cavity structure, arranged outside the transmission shaft, and sleeved on the transmission shaft, with clearance fit, and connected to rotate The outer ring of the bearing 14, the liquid outlet 16 and the liquid inlet 17 of the transmission shaft cooling device 6 are respectively connected to the coolant circulation pipeline, and the other end of the coolant circulation pipeline connected to the liquid outlet 16 is arranged above the interior of the coolant circulation tank , the other end of the coolant circulation pipeline connected to the liquid inlet 17 is c...

Embodiment 3

[0039] A universal pulverizer, such as figure 1or 2, the grinder includes a hopper 1, a crushing chamber 2, a crushing chamber wall 3, a material collection box 5, a drive motor 9, a power switch 10, and a cooling cycle system; the cooling cycle system includes a transmission shaft cooling Device 6, coolant circulation pipeline, circulation pump 12, coolant circulation tank 13; transmission shaft cooling device 6 is a cavity structure, arranged outside the transmission shaft, and sleeved on the transmission shaft, with clearance fit, and connected to rotate The outer ring of the bearing 14, the liquid outlet 16 and the liquid inlet 17 of the transmission shaft cooling device 6 are respectively connected to the coolant circulation pipeline, and the other end of the coolant circulation pipeline connected to the liquid outlet 16 is arranged above the interior of the coolant circulation tank , the other end of the coolant circulation pipeline connected to the liquid inlet 17 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com