Sparingly soluble active component particle, particle preparation and preparation method thereof

An active ingredient and insoluble technology, which is applied in the field of insoluble active ingredient particles, particle preparations and their preparation, can solve the problems of easy aggregation of particles, poor dispersion performance and wettability, and poor dissolution performance of insoluble active ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

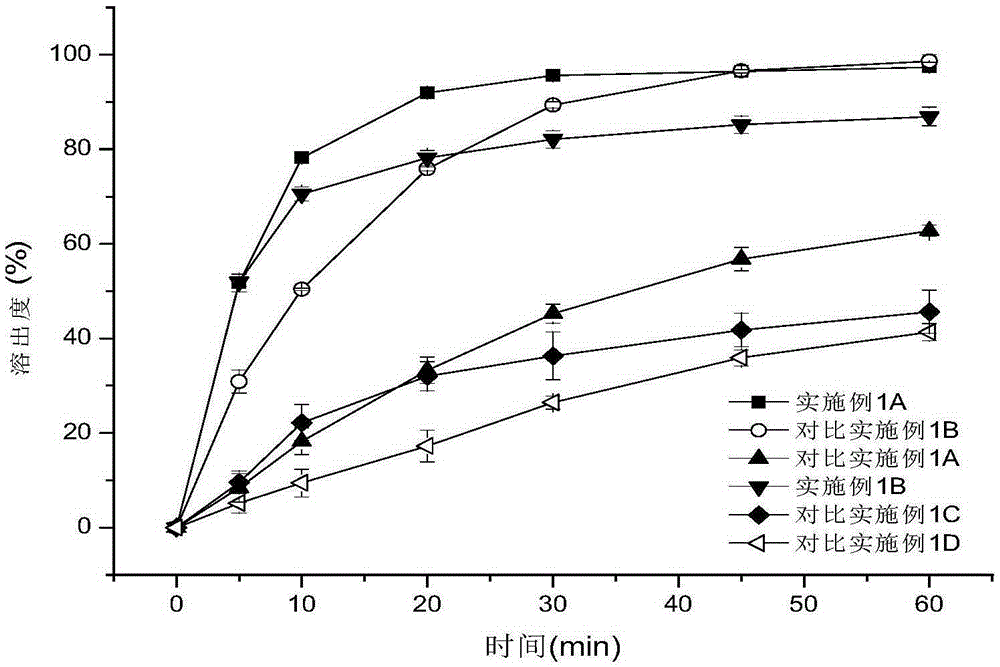

[0147] Embodiment 1 domperidone microparticles

[0148] Disperse 3g of domperidone in 300ml of 30% ethanol, put it in a constant temperature water bath at 25°C, use a stirrer to disperse it at a linear speed of 190 m / min, add a dilute hydrochloric acid solution with a concentration of 8.9% until the domperidone is dissolved, and add acrylic resin Eudragit EPO0.15g, after it dissolves, filter the solution; add a concentration of 9.8% sodium hydroxide solution to the solution at a rate of 0.75ml / min, control the pH of the solution to 7.2, continue stirring for 30min, and filter with suction to obtain The eutectoid was washed 3 times with water, dried at 40°C for 48 hours, then gently ground, and passed through an 80-mesh sieve to obtain a sample (referred to as 1A), with a content of 99.79%.

[0149] Using the above method, only change the amount of acrylic resin Eudragit EPO to 3g, the product obtained is marked as 1B, and the sample content is 102.6%.

Embodiment 1

[0150] Comparative example 1 domperidone microparticles

[0151] Disperse 3g of domperidone in 300ml of 30% ethanol, put it in a 25°C constant temperature water bath, use a stirrer to disperse it at a linear speed of 190 m / min, add a dilute hydrochloric acid solution with a concentration of 8.9% until the domperidone is dissolved, and add PVPK301. 5g, filter this solution after it dissolves; Add concentration to this solution with the speed of 0.75ml / min and be 9.8% sodium hydroxide solution, control solution pH to 7.2 and continue to stir for 30min, suction filtration obtains eutectic, water Wash 3 times, dry at 40°C for 48 hours, grind lightly, and pass through an 80-mesh sieve to obtain a sample (denoted as Comparative 1A), with a content of 99.67%.

[0152] Adopt the above-mentioned method to prepare 3 kinds of domperidone microparticles in addition as contrast, add PVPK30 to 9g in the sample recorded as contrast 1B, other conditions are all unchanged; Add polyethylene gly...

Embodiment 2

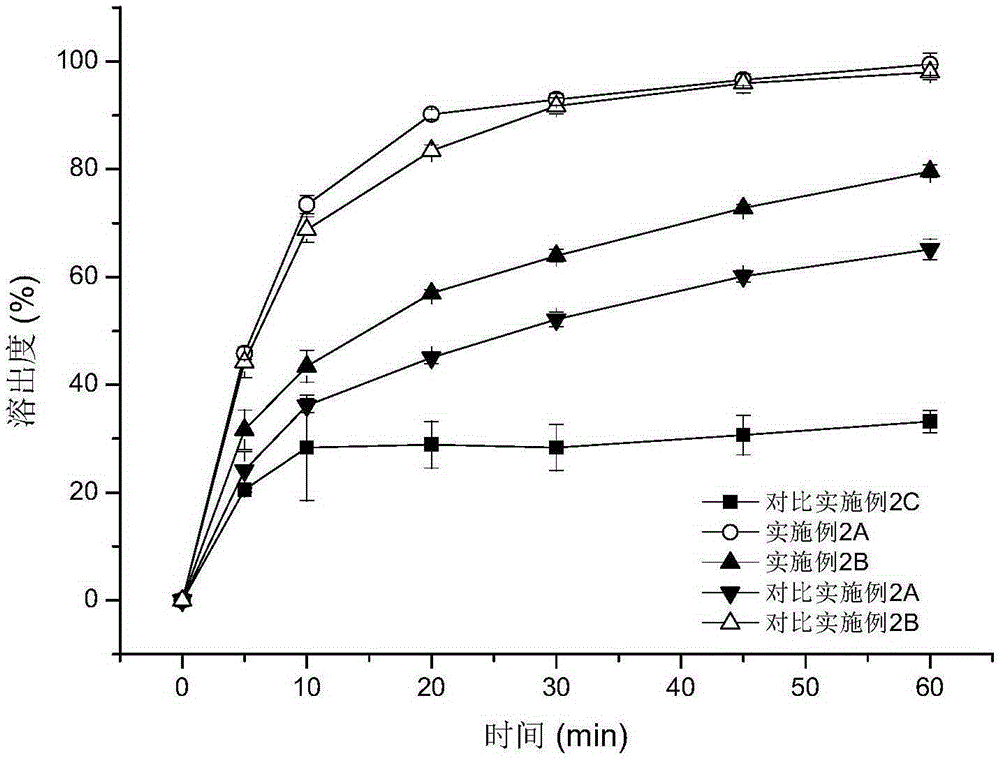

[0153] Embodiment 2 Estradiol microparticles

[0154] Disperse 1g of estradiol in 120ml of 30% ethanol, use a stirrer to disperse it at a linear speed of 250 m / min, then add 0.5g of acrylic resin Eudragit L1000 to it, and disperse it at a speed of 15ml / min Add 9.8% sodium hydroxide solution at a high speed, and continue to stir until the two are completely dissolved; add 8.9% hydrochloric acid solution to the solution at a speed of 15ml / min until the pH of the mixed solution is 5; After washing with water for 5 times, dry under reduced pressure at 55°C for 5 hours; gently grind in a mortar, and pass through an 80-mesh sieve to obtain a sample (denoted as 2A), with a content of 101.5%.

[0155] Using the above method, only change the amount of acrylic resin Eudragit L100 to 0.2g to obtain a sample, denoted as 2B, and the content of the sample is 99.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com