Double-layer sectioned SOI LIGBT device and manufacturing method thereof

A device and double-layer technology, applied in the field of electronics, can solve the problems of lowering the breakdown voltage, poor thermal conductivity of the oxide layer, self-heating effect, etc., and achieve the effect of increasing the breakdown voltage and reducing the self-heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

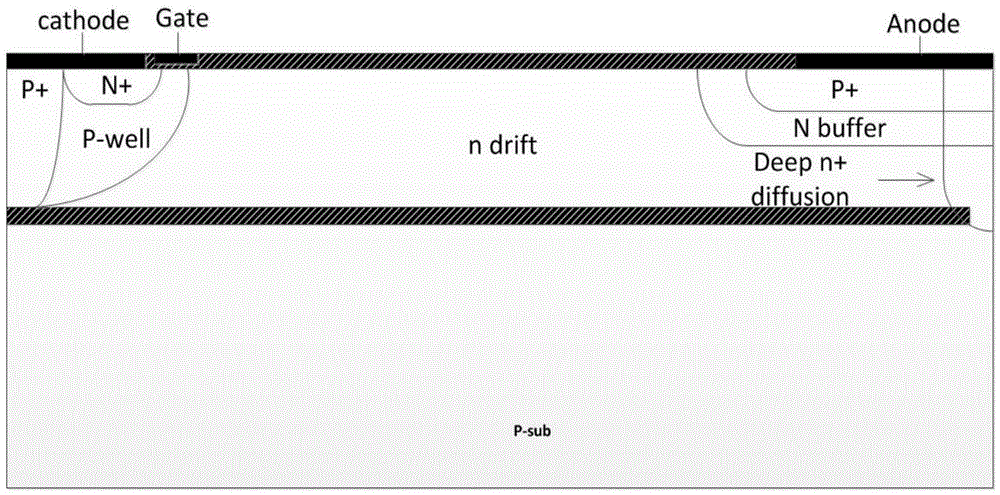

[0025] like figure 1 As shown, the common LIGBT device structure does not have an isolation structure between the working area and the substrate to deal with the leakage current of the substrate, so a large number of holes are directly injected into the substrate in the working state, which seriously affects the device performance.

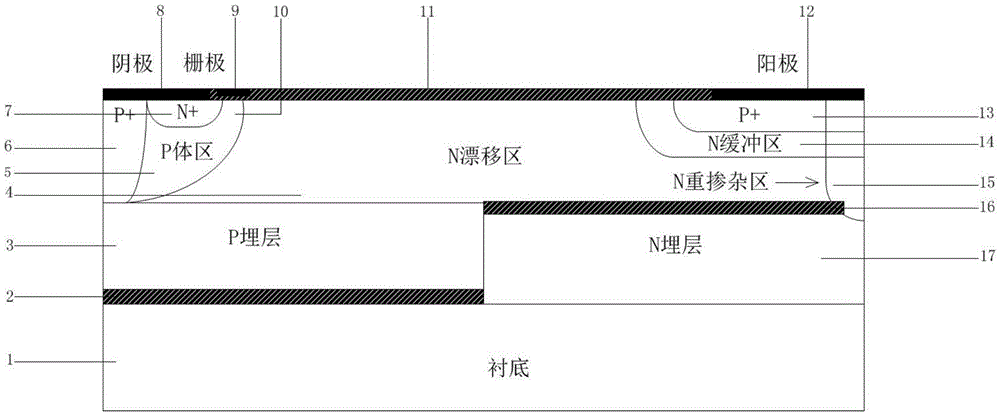

[0026] like image 3 As shown, a double-layer partial SOIL IGBT device includes a silicon substrate 1, on which a first buried oxide layer 2 and an N buried layer 17 are sequentially arranged from left to right, and the upper surface of the N buried layer 17 is higher than the first The upper surface of a buried oxide layer 2, the first buried oxide layer is provided with a P buried layer 3, the N buried layer 17 is provided with a second buried oxide layer 16, the upper surface of the P buried layer 3 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com