Image sensor and image sensor forming method

An image sensor and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of deviation between positions, affecting the uniformity of image sensors, affecting the performance of image sensors, etc., to improve uniformity, Thickness is easy to accurately control and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

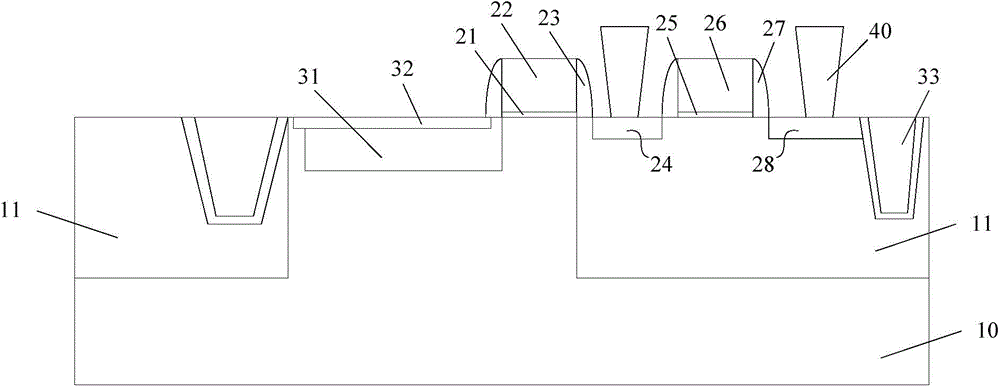

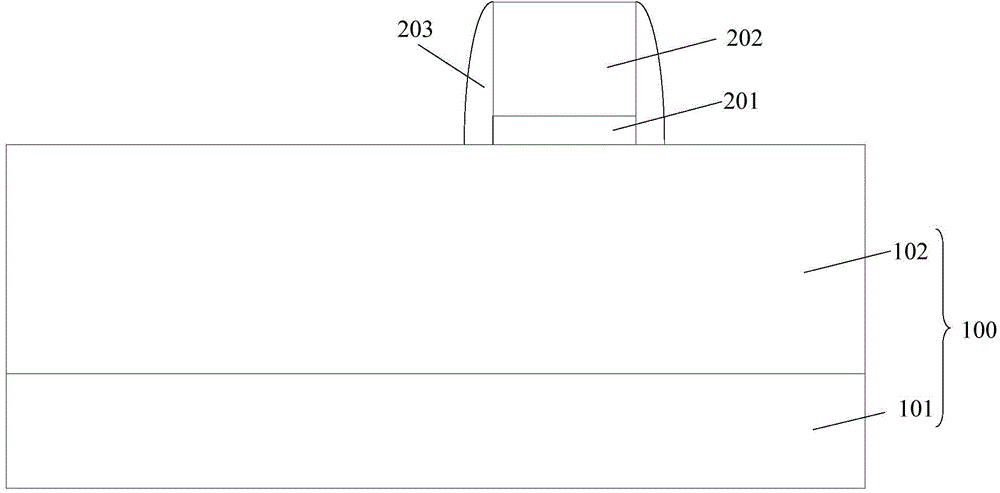

[0034]As mentioned in the background art, the performance of the image sensor formed in the prior art needs to be further improved. There is a part of the N-type doped region between the P-type pinning layer and the channel region of the transfer transistor, and the distance between the P-type pinning layer and the first gate structure is too small, which will cause the P-type pinning layer and the transfer transistor Part of the N-type doped region between the channel regions is pinched off, which affects the transmission of photoelectrons, and the dopant ions in the P-type pinning layer diffuse to the channel region, affecting the transmission of the channel region of the transistor. width. Due to the size of the patterned photoresist layer formed by photolithography, there will be deviations in different pixel units, resulting in different distances between the P-type pinning layer and the first gate structure of different pixel units, so that the N-type doping The channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com