An early dismantling device for steel pipe scaffolding

A scaffolding and steel pipe technology, applied in the field of steel pipe scaffolding, can solve the problems of large application, small degree of freedom of the contact surface, inconvenient operation, etc., and achieve the effects of reducing amortization costs, simple and efficient operation, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

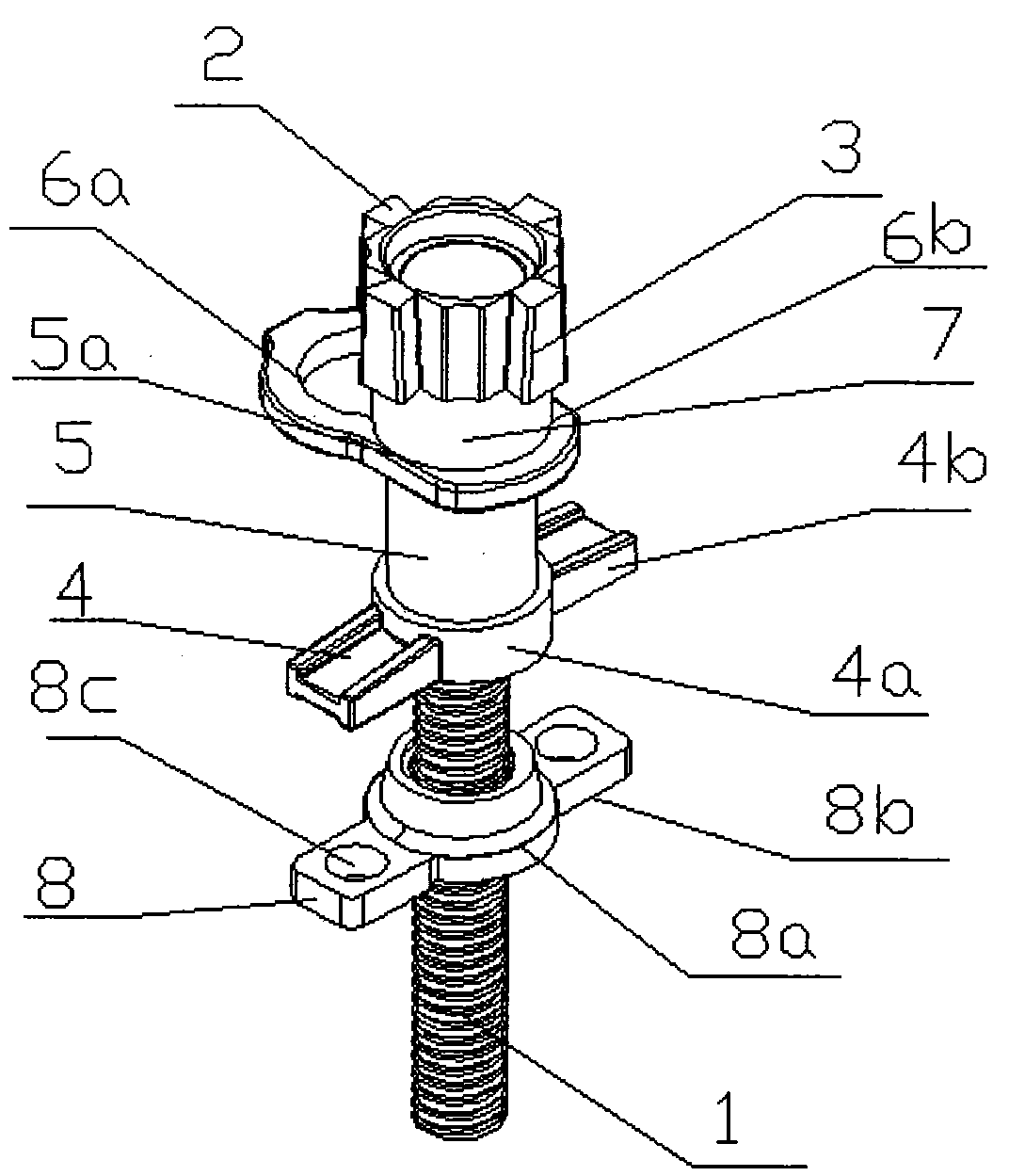

[0024] refer to figure 1 , figure 2 with image 3 As shown, a steel pipe scaffolding early release component provided by the present invention includes an adjusting screw 1 , an early release head and a socket base 2 .

[0025] The surface of the adjusting screw 1 is provided with external threads, and is installed on the top of the vertical rod.

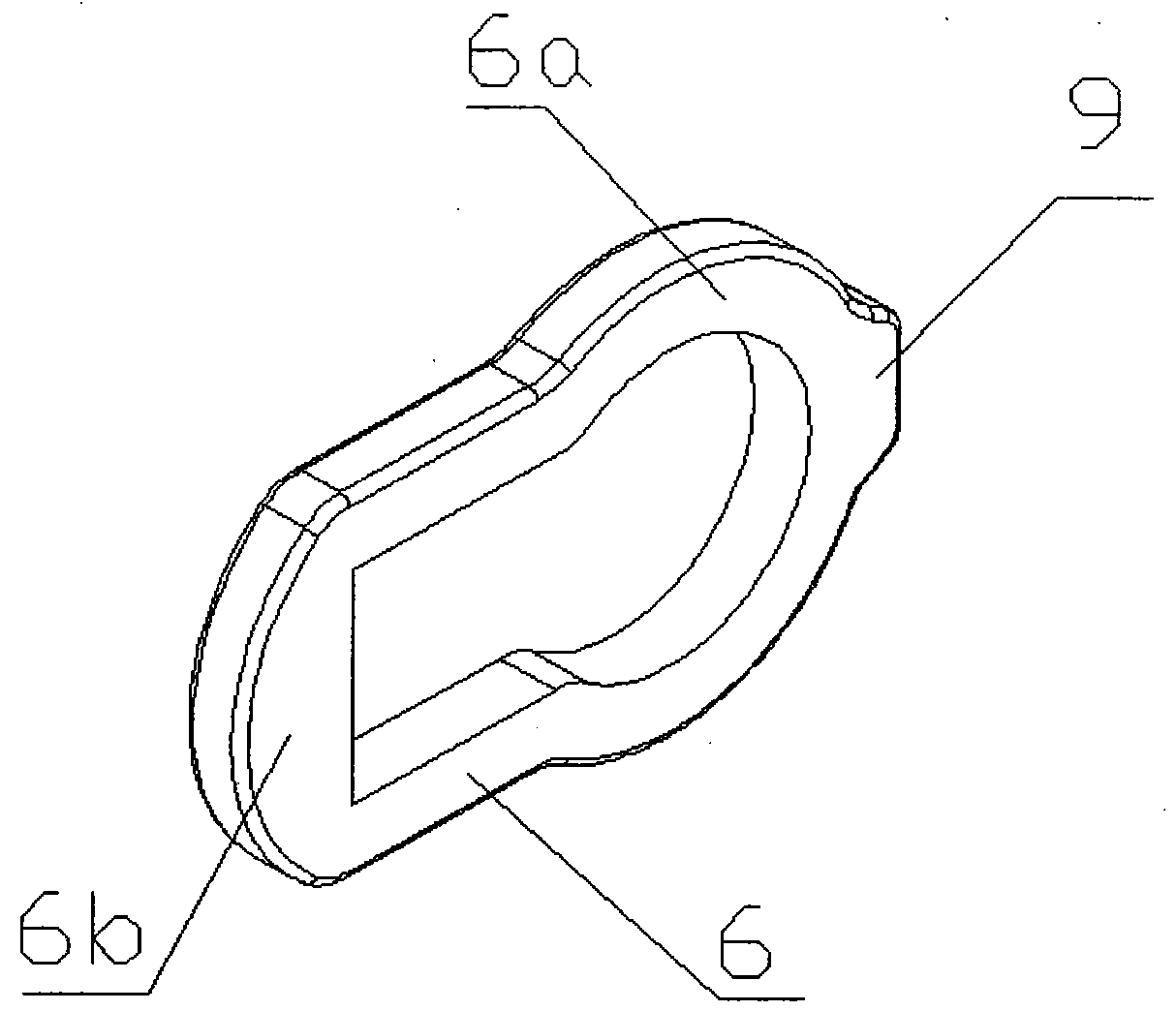

[0026] The early dismantling head includes a bracket 4 , a pipe body 5 and a snap ring 6 . The bracket 4 includes a hollow cylindrical support body 4a and a handle 4b arranged on the support body 4a for rotating the support body 4a. The matching internal thread, the bracket 4 is sleeved on the outside of the adjusting screw 1. The rotating handle 4b drives the bracket 4 to move up and down along the external thread of the adjusting screw 1 to adjust the height of the early dismantling head on the adjusting screw 1 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com