Production method of aroma-enhancing cigarette paper

A production method and technology of cigarette paper, applied in the fields of special paper, paper, papermaking, etc., can solve the problems of cigarette paper miscellaneous gas and low smoking quality, and achieve the effect of improving the grade of cigarettes, increasing the fragrance and enriching the fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

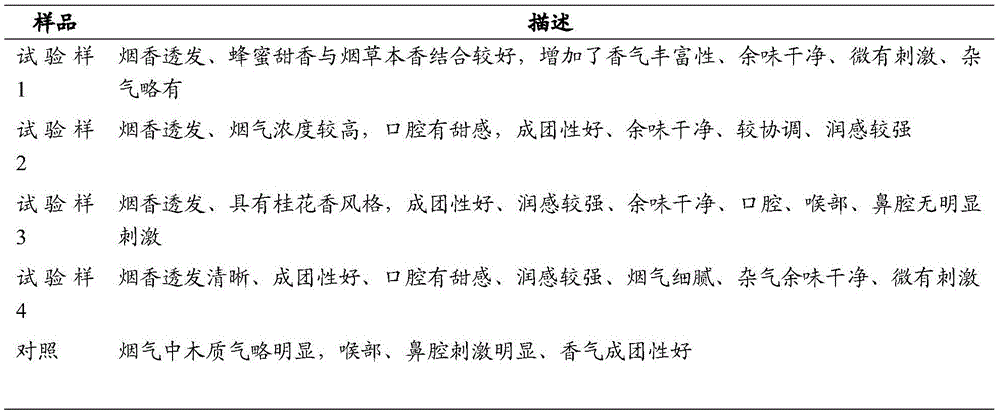

Examples

Embodiment 1

[0015] (1) Add 500 g of glycerin, 800 g of alcohol and 20 g of pectin to 300 g of milk vetch honey and 300 g of wild vetch honey in the market, and fully emulsify through a colloid mill to prepare a colloidal solution as an ink.

[0016] (2) The cigarette paper base is printed on the machine, and the ink coating amount is 10g / m 2 .

[0017] (3) Using an embossing roller to perform embossing treatment directly after drying to make a cigarette paper sample.

Embodiment 2

[0019] (1) Add 800 g of glycerin, 1000 g of alcohol and 30 g of pectin to 500 g of commercially available linden honey and 1000 g of milk vetch honey, and fully emulsify through a colloid mill to prepare a colloidal solution as an ink.

[0020] (2) The cigarette paper base is printed on the machine, and the ink coating amount is 15g / m 2 .

[0021] (3) Using an embossing roller to perform embossing treatment directly after drying to make a cigarette paper sample.

Embodiment 3

[0023] (1) Add 500 g of glycerin, 700 g of alcohol and 18 g of pectin to 1000 g of commercially available sweet-scented osmanthus honey, and fully emulsify through a colloid mill to prepare a colloidal solution as an ink.

[0024] (2) The cigarette paper base is printed on the machine, and the ink coating amount is 12g / m 2 .

[0025] (3) Using an embossing roller to perform embossing treatment directly after drying to make a cigarette paper sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com