K65 control-rolled steel plate and longitudinal submerged arc welded pipe used in frigid zone and manufacturing method of longitudinal submerged arc welded pipe

A technology of straight seam submerged arc welding and alpine regions, which is applied in manufacturing tools, arc welding equipment, welding equipment, etc. It can solve the problems that the performance cannot meet the requirements and the steel pipe cannot be used in alpine regions, and achieve the effect of ensuring low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a K65 controlled rolling steel plate with a width of 4355 mm and a thickness of 23 mm.

[0044] The mass percentage of each component of the K65 controlled-rolled steel plate is shown in Table 1:

[0045] Table 1 The mass percentage of each component of the K65 controlled-rolled steel plate in this embodiment

[0046] C

mn

Si

P

S

Mo

Ni

Cr

0.04-0.05

1.60-1.66

0.20-0.24

0.007-0.01

0.001-0.003

0.007-0.008

0.218-0.224

0.223-0.229

Cu

Al

N

B

(V+Nb+Ti)%

Ceq%

Pcm%

Fe

0.132-0.144

0.036-0.041

0.004-0.006

0.0001-0.0002

0.091-0.099

0.39

0.16

margin

[0047] The rolling process parameters are: adopt the steel slab with the mass percentage of each component shown in Table 1, the starting rolling temperature of the intermediate slab is 880-950°C, the finish rolling temperature of the steel plate is 60-70°C above t...

Embodiment 2

[0053] This embodiment provides a K65 controlled rolling steel plate with a width of 4340 mm and a thickness of 27.7 mm.

[0054] The mass percentage of each component of the K65 controlled-rolled steel plate is shown in Table 3:

[0055] Table 3 Mass percentage of each component of K65 controlled-rolled steel plate in this embodiment

[0056] C

mn

Si

P

S

Mo

Ni

Cr

0.04-0.06

1.59-1.65

0.20-0.23

0.006-0.01

0.001-0.003

0.007-0.008

0.211-0.229

0.218-0.227

Cu

Al

N

B

(V+Nb+Ti)%

Ceq%

Pcm%

Fe

0.133-0.147

0.036-0.042

0.004-0.005

0.0001-0.0002

0.086-0.222

0.37-0.41

0.15-0.17

margin

[0057] The parameters of the rolling process are as follows: the steel slabs with the mass percentages of the above components are used, the starting rolling temperature of the intermediate slab is 880-950°C, the final rolling temperature of the steel plate is ...

Embodiment 3

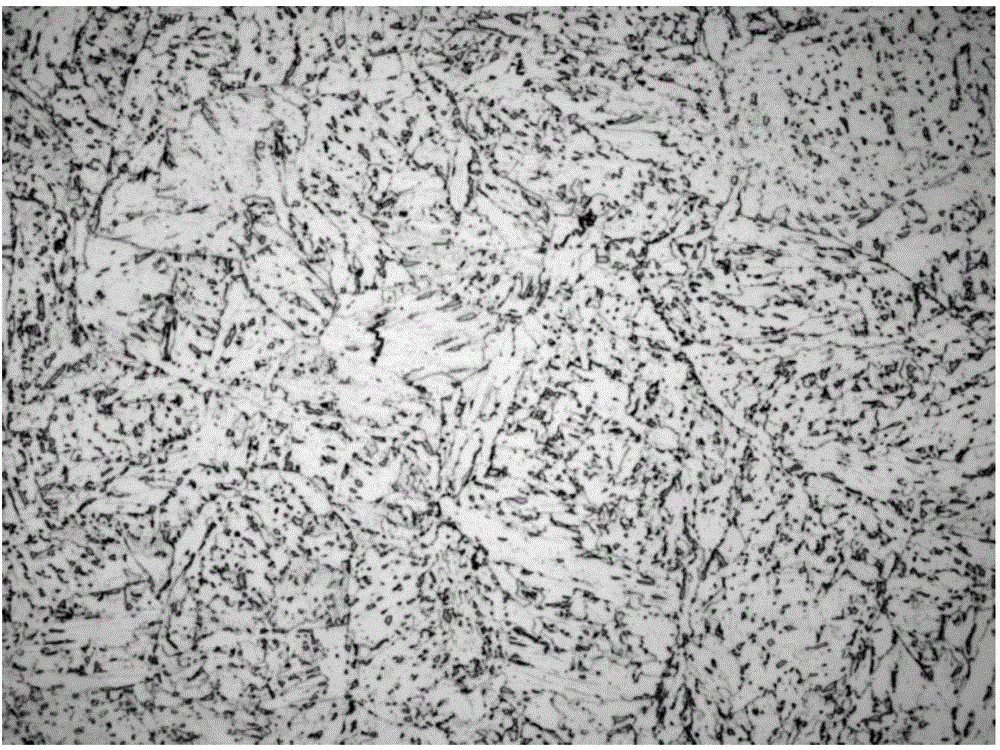

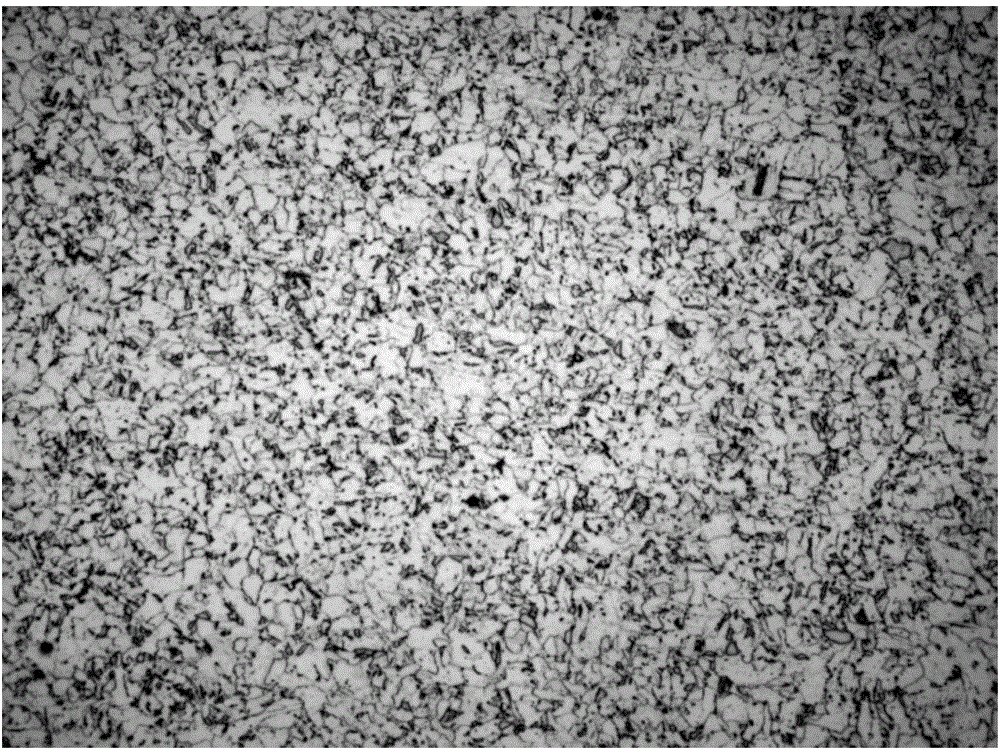

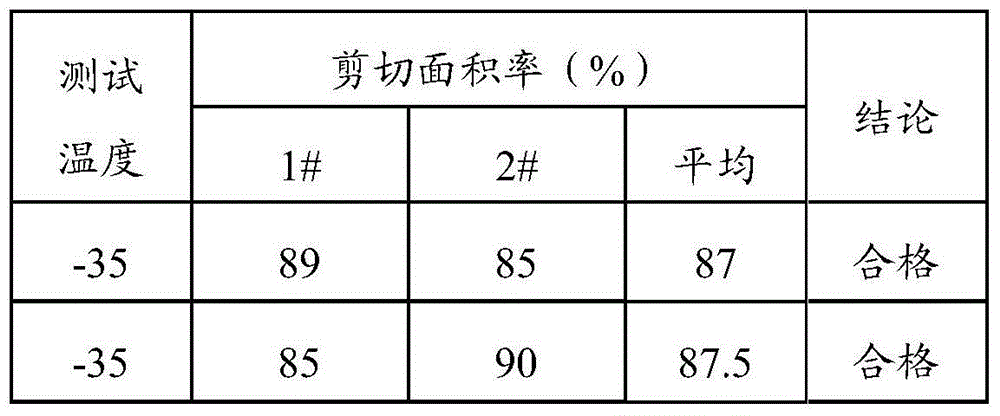

[0063] This embodiment provides a diameter A K65 steel straight seam submerged arc welded pipe with a thickness of 23 mm and a manufacturing method thereof.

[0064] The steel pipe of this example uses the K65 controlled-rolled steel plate obtained in Example 1 as the base material, and has undergone edge milling, pre-bending, JCO forming, pre-welding, internal welding, external welding, the first ultrasonic inspection, and the first X-ray inspection. , mechanical diameter expansion, hydraulic test, chamfering, groove processing, second ultrasonic inspection, second X-ray inspection, magnetic particle inspection of pipe end and appearance quality inspection before forming. in,

[0065] In the edge milling step, the angle of the upper and lower grooves is 35°, the height of the upper groove is 8.0mm, and the thickness of the blunt edge is 6.5mm.

[0066] In the JCO molding step: the entire pressing pass is 27 passes, and the amount of each reduction is 585mm.

[0067] In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com