Turbine oil composition and method for improving performance of steam turbine oil

A technology of turbine oil and composition, applied in the directions of lubricating composition, petroleum industry, additives, etc., can solve problems such as long water separation time, problems in oil-water separation performance, incomplete water separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

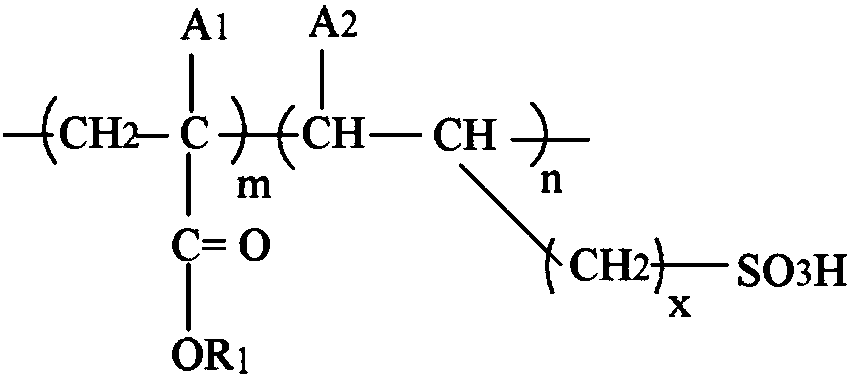

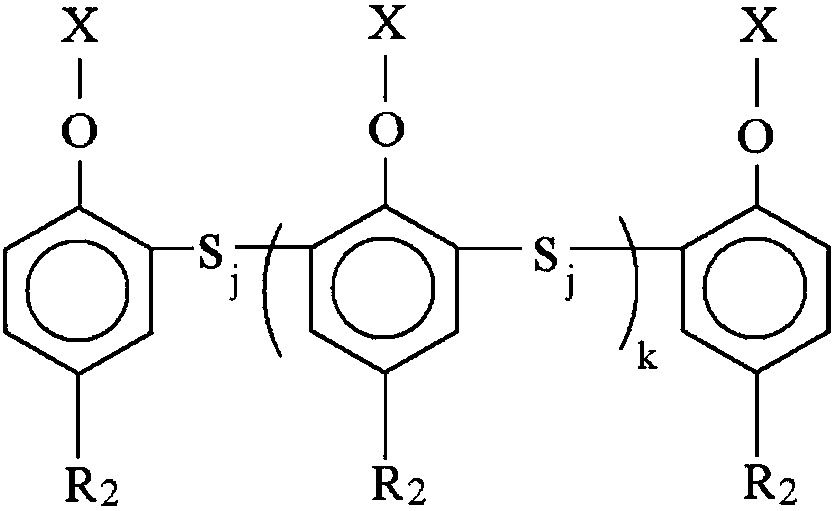

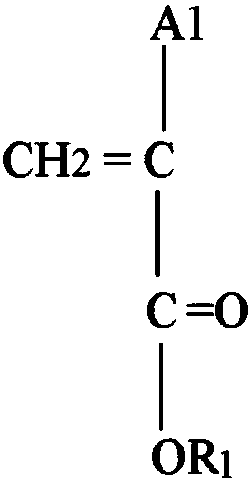

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The preparation of embodiment 1 tertiary dodecyl mercaptan hexanoate

[0062] In a 500mL three-necked flask with a motor stirrer and reflux water separation and condensation facilities, add 80 grams of No. 120 solvent gasoline, 100 grams of tert-dodecyl mercaptan (M=202.4, 0.49mol), and then add 15 grams of 98 % concentrated sulfuric acid, control the reaction temperature to be 90°C, add 56.9 grams of hexanoic acid (M=116.2, 0.49mol) dropwise with a separatory funnel, the time for the addition is 1 hour, then reflux for 3 hours, and separate the water in the reaction , when the water content reaches 8.7 grams (98.6%), stop the reaction, cool down, separate the vitriol oil, then wash the oil layer with deionized water until neutral, then distill the solvent under reduced pressure to obtain 146 grams of oily liquid, which is Tert-dodecyl mercaptan hexanoate S-1, S content 10.2%.

Embodiment 2 10

[0063] The preparation of embodiment 2 tetradecyl mercaptan propionate

[0064] In a 500mL three-neck flask equipped with a motor stirrer and reflux water separation and condensation facilities, add 60 grams of No. 120 solvent gasoline, 90 grams of tetradecyl mercaptan (M=230.45, 0.39mol), and then add 11 grams of concentrated sulfuric acid , control the reaction temperature to be 95°C, add 28.9 grams of propionic acid (M=74, 0.39mol) dropwise with a separatory funnel, the dropwise addition time is 1.2 hours, then reflux for 4 hours, and separate the water in the reaction. When reaching 6.9 grams (98.3%), stop the reaction, lower the temperature, separate the water layer, then wash the oil layer with deionized water until neutral, then distill the solvent under reduced pressure to obtain 111.3 grams of oily liquid, which is tetradecyl Thiol propionate S-2, the S content is 11.3%.

Embodiment 3

[0065] The preparation of embodiment 3 propylene sulfonic acid mixtures

[0066] Add 80 grams of petroleum ether at 30°C to 60°C in a 500mL corrosion-resistant autoclave with stirring, heating, and cooling bath, then close the reactor, turn on the stirring, and pass it into a cooling bath for temperature control, and then use a high-pressure pump to Add 40 grams (0.952 mol) of propylene, and feed high-purity nitrogen, control the pressure of the reactor between 0.8 and 1 MPa, control the temperature of the reactor at 0 to 10°C, heat the cylinder containing sulfur trioxide, and place Measure on an electronic scale, and then control the heating temperature so that the pressure of the sulfur trioxide cylinder is greater than the pressure of the autoclave, and open the outlet valve of the sulfur trioxide cylinder, and then pass the gas into the vent pipe of the autoclave, and then into the liquid phase of the autoclave Carry out the sulfonation reaction in the middle, the amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com