A short-process pre-separation water treatment device for oilfield produced fluid

A technology of water treatment device and production fluid, which is applied in the direction of multi-stage serial refining process, hydrocarbon oil treatment, petroleum industry, etc., and can solve the problems such as the solid content of the water outlet of the device is not up to standard, and the device cannot separate mud and sand, etc. Achieve the effect of reducing construction investment, occupying less land, and reducing the volume of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

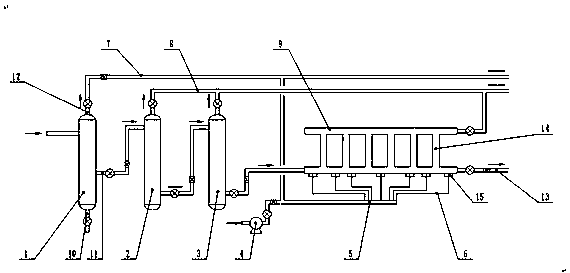

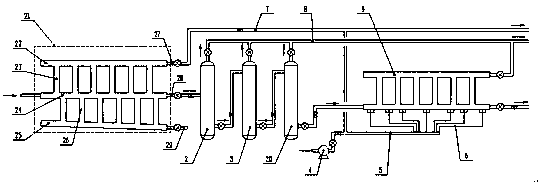

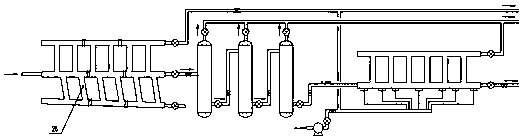

[0030] See figure 1 and Figure 9 As shown, the primary oil-water separation cyclone 2 and the secondary oil-water separation cyclone 3 are connected in series, and the middle outlet of the primary oil-water separation cyclone 2 is connected with the inlet of the secondary oil-water separation cyclone 3. The upper outlets of the secondary oil-water separation cyclone are all connected to the oil discharge pipeline 8; It is also connected to the cyclone 1. The outlet of the upper horizontal pipe of the trapezoidal pipe is connected with the oil discharge pipeline 8, and the outlet of the lower horizontal pipe is connected with the drain pipeline 13 to discharge the separated water.

[0031] The cyclone 1, the primary oil-water separation cyclone 2 and the secondary oil-water separation cyclone 3 are all cyclones, and their structure and working principle are basically the same as "an axial flow cyclone separator with the same direction of flow , Chinese Patent, Patent Applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com