Lubricating oil composition and method for improving detergency of lubricating oil

A technology of lubricating oil composition and compound detergent, which is applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of detergency and various performances that cannot meet the requirements, and achieve excellent anti-emulsification performance, fast water separation, The effect of excellent high temperature detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 catalyst preparation

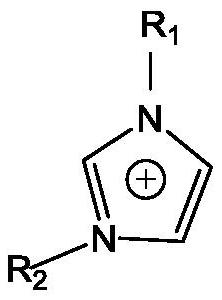

[0058] Synthesis of IL-1 as catalyst of 1-methyl-3-butylimidazole boron tetrafluoride salt-metaphosphoric acid-sodium dodecylbenzenesulfonate

[0059] Add 1mol N-methylimidazole and 1.05mol 1-bromobutane into a three-necked flask, 2 After purging for 20mim, start stirring and heat to 85°C for 30-36h. After the reaction was completed, it was left to cool down to room temperature, the lower layer of the solution was light yellow, and the upper layer was unreacted raw materials. The upper layer liquid was decanted, 3 times the volume of ethyl acetate was added to the lower layer liquid to wash, and then the ethyl acetate was separated to remove unreacted raw materials. After washing, dry at 70°C for 24 hours to obtain light yellow viscous 1-methyl-3-butylimidazolium bromide.

[0060] The obtained 1-methyl-3-butylimidazolium bromide was dissolved in dichloromethane, and NaBF was added thereto 4 Aqueous solution with a content of 1mol ...

Embodiment 2

[0062] Example 2 Salicylic acid alkylation reaction catalyzed by IL-1

[0063] In a 500mL three-necked flask, add 20 grams of catalyst IL-1, 100 grams of C 16 α-Olefin (Mn=224.4, 0.446 mol), 70.78 g of salicylic acid (Mn=138.12, 0.512 mol), nitrogen gas was introduced, stirring was started, heating was controlled at a temperature between 140°C and 142°C, and the reaction was carried out for 5 hours.

[0064] After the reaction, the temperature of the three-necked flask was lowered. When the temperature of the material dropped below 40° C., the stirring was stopped, and 150 grams of No. 120 solvent gasoline was added. The materials in the three-necked flask were taken out, placed in a separatory funnel to separate layers, and the oil phase in the upper layer was collected, and the ionic liquid in the lower layer could be reused. Add 300 grams of distilled water to wash three times in the oil phase, remove unreacted salicylic acid in the oil phase, and dry the oil phase with an...

Embodiment 3

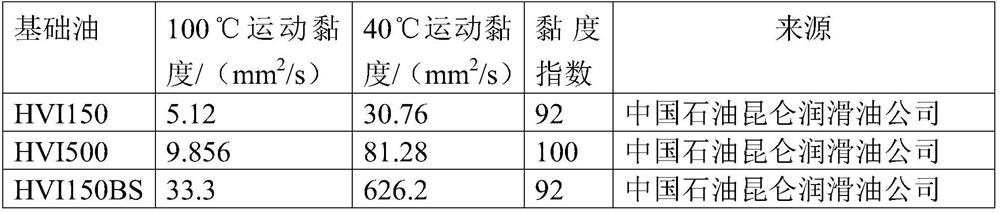

[0066] Implementation of the synthesis of 3 polymethacrylates PMA1

[0067] In the three-necked flask, add 40 grams of base oil 150SN (produced by Sinopec Yanshan Petrochemical, with a kinematic viscosity of 5.7mm at 100°C) 2 / s), 15 grams of decyl methacrylate, 5 grams of methyl methacrylate, 30 grams of myristyl methacrylate, 10 grams of dodecyl methacrylate, adding 0.08 grams of azobisisobutyronitrile, Introduce nitrogen to protect the reactant, turn on the stirring and raise the temperature to 75°C. At this time, it is observed that the reactant has obvious exotherm, and the reaction temperature is controlled at 90°C. After 2 hours of prepolymerization, the material becomes viscous obviously, and then add 0.05 grams of azo For diisobutyronitrile, the temperature was gradually increased to 105°C for 5 hours of copolymerization reaction, and a light yellow viscous liquid was obtained. Under nitrogen protection, the reacted material was lowered to 25°C to obtain a tetrapolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com