A kind of lubricating oil composition and preparation method thereof

A technology for lubricating oil composition and base oil, applied in the field of lubricating oil, can solve problems such as reducing detergency, and achieve the effects of avoiding corrosion and corrosive wear, excellent high-temperature detergency, and excellent detergency and dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

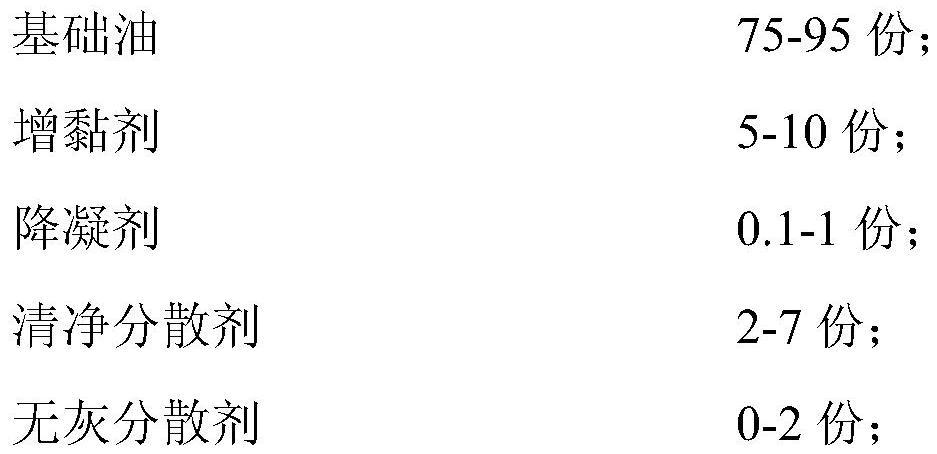

[0034] A lubricating oil composition, including the following components by weight:

[0035]

[0036] Its production method is:

[0037] Step 1, after weighing the raw materials by weight, first mix the different clean dispersants and different ash dispersants, and preheated to 90 degrees Celsius, to obtain a dispersion additive;

[0038] Step 2, heat the proosing agent to 55 degrees Celsius;

[0039] Step three, mix the plurality of antioxidant preservatives uniform, and preheated to 55 degrees Celsius;

[0040] Step 4, mix a variety of tackifiers uniform, and preheated to 135 degrees Celsius;

[0041] Step 5, the base oil is added to the tone and the tank, and after the stirring conditions of 1350 rpm, after heating to 75 degrees Celsius, the preheated tackifier, preheating duisant, preheating clean dispersion additive And preheated antifoleal projection, then stirred at 75 degrees Celsius to dispersion, filtration, dispensing, and

Embodiment 2

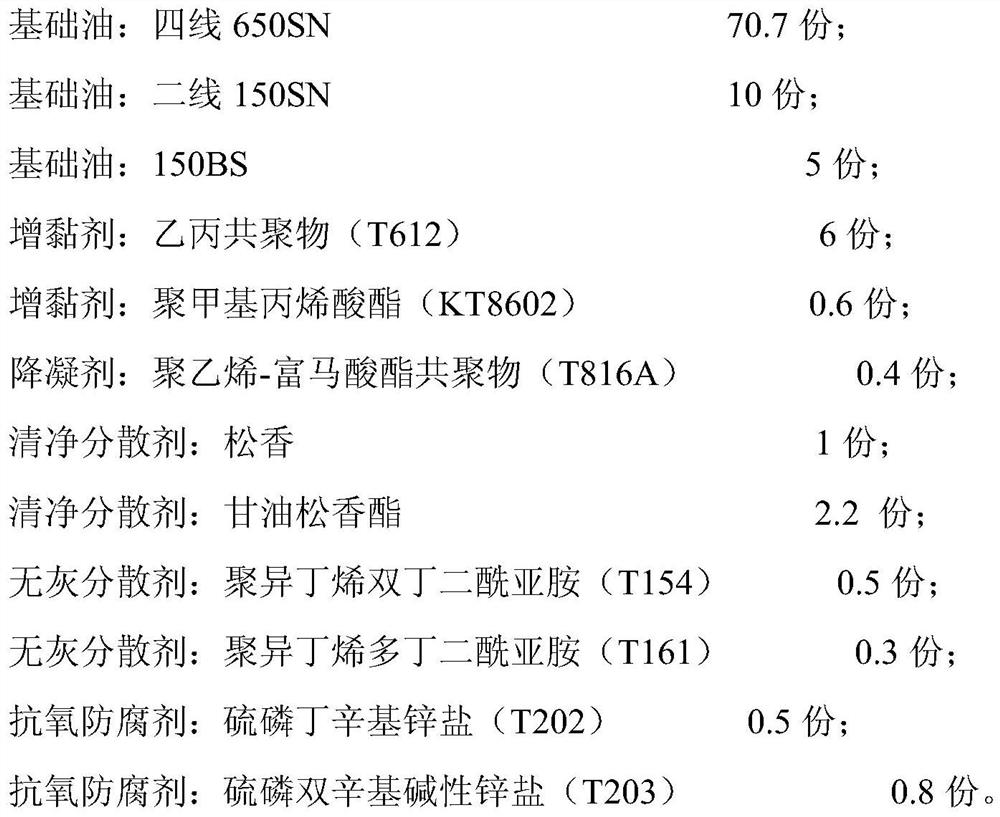

[0043] A lubricating oil composition, including the following components by weight:

[0044]

[0045] Its production method is: as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com