Lubricating oil composition and method for improving its comprehensive performance

A lubricating oil composition and composition technology, applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of water separation and demulsification performance that cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

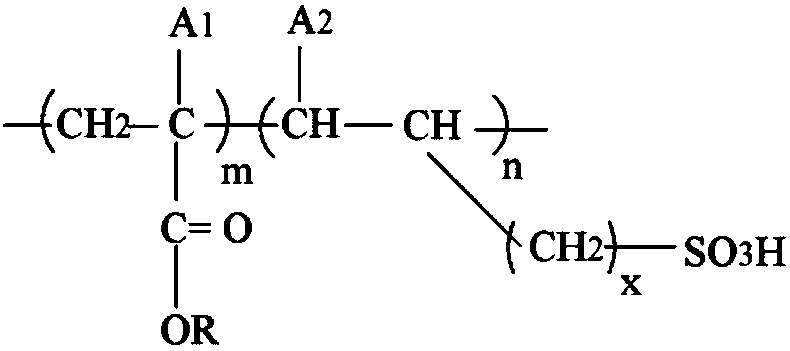

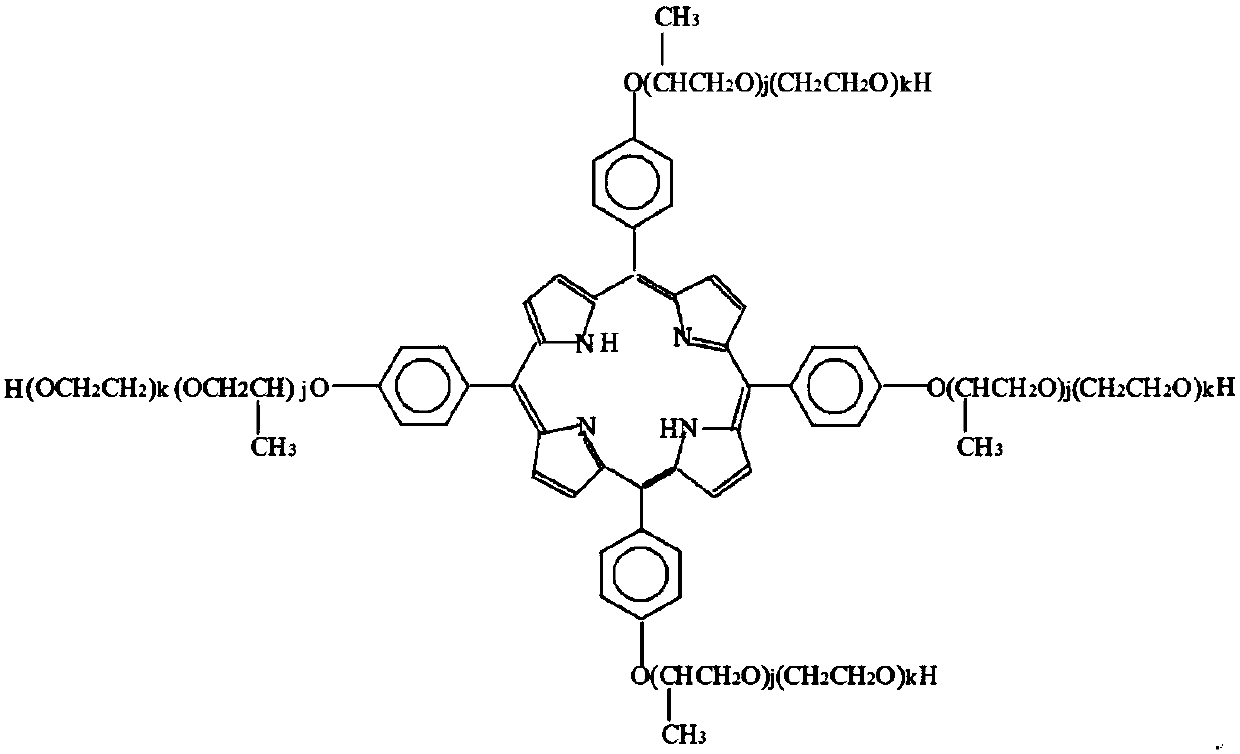

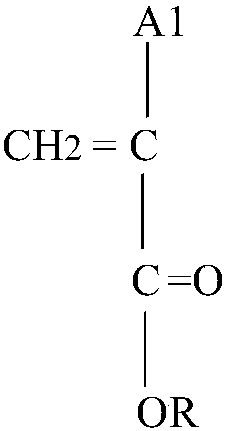

Method used

Image

Examples

Embodiment 1 10

[0072] The preparation of embodiment 1 octadecylthiophosphonic anhydride H-1

[0073]In a 500mL three-neck flask equipped with a motor stirrer and reflux water separation and condensation facilities, add 100 grams of C18α-olefins (0.4mol), 100 grams of HVI150 neutral oil, 50 grams of phosphorus pentasulfide (0.23mol), and then add 0.75 grams of sulfur , control the reaction temperature to 150°C, at this time, hydrogen sulfide gas is released, absorb hydrogen sulfide gas with 20% sodium hydroxide solution, react at this temperature for 5 hours, stop the reaction, lower the temperature, and filter out the unreacted phosphorus pentasulfide residue , Obtain 236 grams of oily liquid, i.e. octadecylthiophosphonic anhydride H-1, S content 9.3%, P content 3.8%.

Embodiment 2 20

[0074] The preparation of embodiment 2 tetracosyl thiophosphonic anhydride H-2

[0075] In a 500mL three-necked flask equipped with a motor stirrer and reflux water separation and condensation facilities, add 100 grams of C24α-olefins (0.3mol), 80 grams of HVI150 neutral oil, 36 grams of phosphorus pentasulfide (0.16mol), and then add 0.6 grams of nonyl Base phenol, control the reaction temperature to 180°C, at this time, hydrogen sulfide gas is released, absorb hydrogen sulfide gas with 20% sodium hydroxide solution, control the reaction at this temperature for 6 hours, stop the reaction, cool down, and filter to separate the unreacted Phosphorus pentasulfide residue was obtained to obtain 201 g of oily liquid, i.e. tetracosylthiophosphonic anhydride H-2, with an S content of 7.7% and a P content of 2.9%.

Embodiment 3

[0076] The preparation of embodiment 3 propylene sulfonic acid mixtures

[0077] Add 80 grams of petroleum ether at 30°C to 60°C in a 500mL corrosion-resistant autoclave with stirring, heating, and cooling bath, then close the reactor, turn on the stirring, and pass it into a cooling bath for temperature control, and then use a high-pressure pump to Put in 40 grams (0.952mol) of propylene, and feed high-purity nitrogen, control the pressure of the reactor between 0.8~1MPa, control the temperature of the reactor at 0~10°C, heat the steel cylinder storing sulfur trioxide, and Measure on the electronic scale, then control the heating temperature so that the pressure of the sulfur trioxide cylinder is greater than the pressure of the autoclave, and open the outlet valve of the sulfur trioxide cylinder to pass the gas into the vent pipe of the autoclave, and then into the liquid phase of the autoclave Carry out sulfonation reaction, sulfur trioxide feed rate is 77.7 grams (0.971mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com