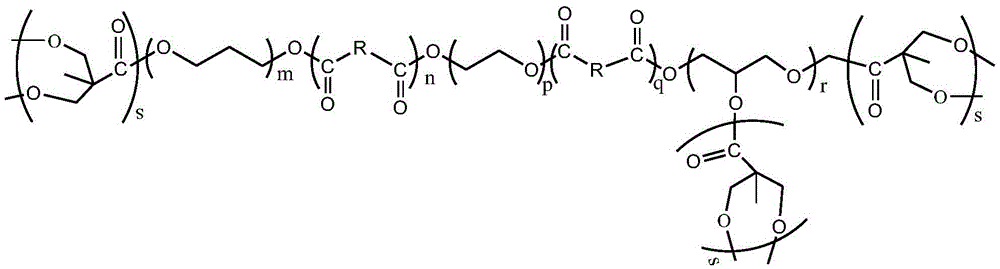

Hyper-branched polyester polyol and preparation method thereof

A hyperbranched polyester and polyol technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low softening breakdown temperature, low inflection point temperature, and high raw material prices, and achieve low production costs. The method is simple and the effect of increasing the cross-linking point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

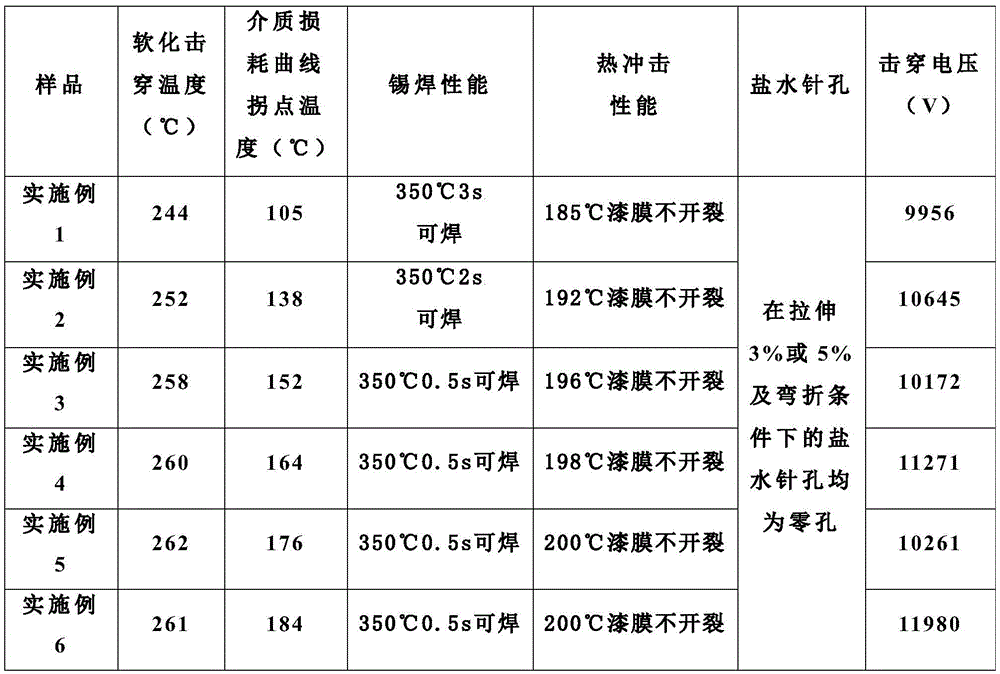

Embodiment 1

[0043] Preparation of polyester polyol

[0044] Add 495.1g terephthalic acid, 581.2g phthalic anhydride, 307.1g adipic acid, 254.7g ethylene glycol, 617.6g glycerol, 186.5g 2-methyl-1,3-propanediol and 24.4g zinc acetate into the reactor in sequence . Start the heating device, slowly increase the temperature to 190°C, maintain the temperature for about 1 hour, and slowly increase the temperature to 210°C until the system is completely clear and transparent. 1470.6 g of xylene was added, and the reaction was maintained at 210°C for 1 hour. Exhaust xylene at 210°C and 0.03-0.05MPa negative pressure for 15 minutes.

Embodiment 2

[0046] Preparation of hyperbranched polyester polyol

[0047] Add 1122.8g of 2,2-dimethylolpropionic acid and 35.6g of p-toluenesulfonic acid into the reaction kettle, and slowly raise the temperature to 180°C for about 3 to 4 hours. Add 1663.5g of xylene and maintain 180°C for about 3 hours. Extract xylene at 180°C and 0.03-0.05MPa negative pressure for 30 minutes.

Embodiment 3

[0049] One-step preparation of hyperbranched polyester polyol (1:2)

[0050] Add 2245.6g of 2,2-dimethylolpropionic acid and 46.9g of p-toluenesulfonic acid into the reaction kettle, and slowly raise the temperature to 180° C. to react for about 3 to 4 hours. Add 1856.4g of xylene and maintain 180°C to react for about 3 hours. Extract xylene at 180°C and 0.03-0.05MPa negative pressure for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com