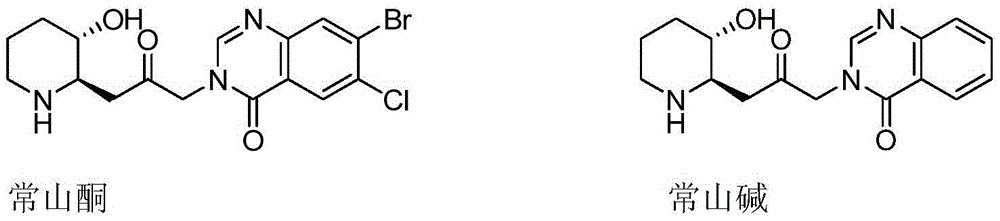

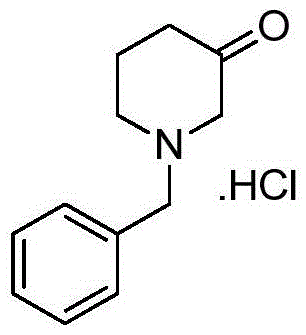

Preparation method for 1-benzyl-3-piperidone hydrochloride

A technology of piperidone hydrochloride and benzylglycine ethyl ester is applied in the field of preparation of 1-benzyl-3-piperidone hydrochloride, can solve the problem of high cost, achieve good quality, short synthesis steps, The effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

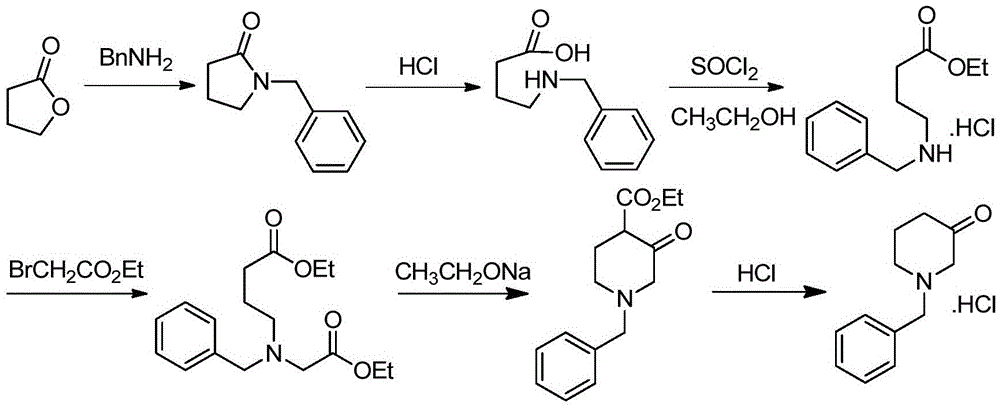

Image

Examples

Embodiment 1

[0034] Embodiment 1 prepares 1-benzyl-3-piperidone hydrochloride

[0035] Follow the steps below:

[0036] (1) Preparation of Intermediate IV

[0037] 43g (0.4mol) of benzylamine, 250mL of acetonitrile, 13.3g (0.04mol) of tetrabutylammonium hydrogen sulfate, and 40.4g (0.4mol) of triethylamine were added successively to a 1000mL three-necked flask. A solution of 49g (0.4mol) of ethyl acetate and 150mL of acetonitrile, keep it warm at 25-28°C for 4h after dropping, HPLC detects that the reaction is complete, cool the reaction solution to 0-5°C and let it stand for 1.5h, filter, and depressurize the filtrate Concentrate to obtain 80.5 g (104% yield) of a light brown oily substance (ie Intermediate IV), with a purity of 98.2% as detected by HPLC, which is directly put into the next reaction.

[0038] (2) Preparation of Intermediate III

[0039] Add 80.5g (0.4mol) of intermediate IV prepared in the previous step to a 1000mL three-necked flask, add 500mL of tetrahydrofuran to di...

Embodiment 2

[0044] Embodiment 2 prepares 1-benzyl-3-piperidone hydrochloride

[0045] Follow the steps below:

[0046] (1) Preparation of Intermediate IV

[0047]43g (0.4mol) of benzylamine, 250mL of dichloromethane, 45.6g (0.2mol) of benzyltriethylammonium chloride, and 154.8g (1.2mol) of diisopropylethylamine were successively added to a 1000mL three-necked flask. Stir, add dropwise a solution of 217.3g (1.2mol) of ethyl bromoacetate and 150mL of dichloromethane, keep warm at 25-28°C for 4 hours after dropping, HPLC detects that the reaction is complete, and cool the reaction solution to 0-5°C Let stand for 1.5h, filter, and concentrate the filtrate under reduced pressure to obtain 75.5g (yield 97.7%) of a light brown oily substance (ie, intermediate IV), with a purity of 98.4% as detected by HPLC, which was directly put into the next reaction.

[0048] (2) Preparation of intermediate III

[0049] Add 75.5g (0.39mol) of intermediate IV prepared in the previous step to a 1000mL three-...

Embodiment 3

[0054] Embodiment 3 prepares 1-benzyl-3-piperidone hydrochloride

[0055] Follow the steps below:

[0056] (1) Preparation of Intermediate IV

[0057] 43g (0.4mol) of benzylamine, 250mL of toluene, 15g (0.057mol) of dodecyltrimethylammonium chloride, and 39.5g (0.5mol) of pyridine were successively added to a 1000mL three-necked flask. A solution of 55 g (0.45 mol) of ethyl chloroacetate and 150 mL of toluene, after dropping, keep it warm at 25-28 ° C for 4 h, after the reaction is detected by HPLC, the reaction solution is cooled to 0-5 ° C and allowed to stand for 1.5 h, filtered, and the filtrate Concentrated under reduced pressure to obtain 81.0 g (yield 105%) of a light brown oily substance (ie Intermediate IV), with a purity of 96.2% as detected by HPLC, which was directly put into the next reaction.

[0058] (2) Preparation of intermediate III

[0059] Add 1.0g (0.42mol) of the intermediate IV prepared in the previous step to a 1000mL three-necked flask, add 500mL of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com