Sulphate aluminum cement clinker and preparation method thereof and sulphate aluminum cement

A technology of sulphoaluminate cement and clinker, which is applied in clinker production, cement production, etc., can solve the problems of high firing temperature, achieve the effects of improving comprehensive performance, reducing mixing ratio, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

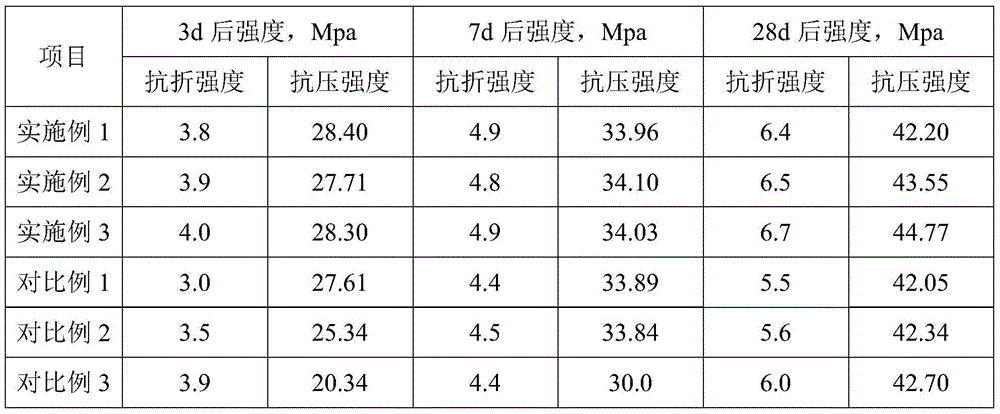

Embodiment 1

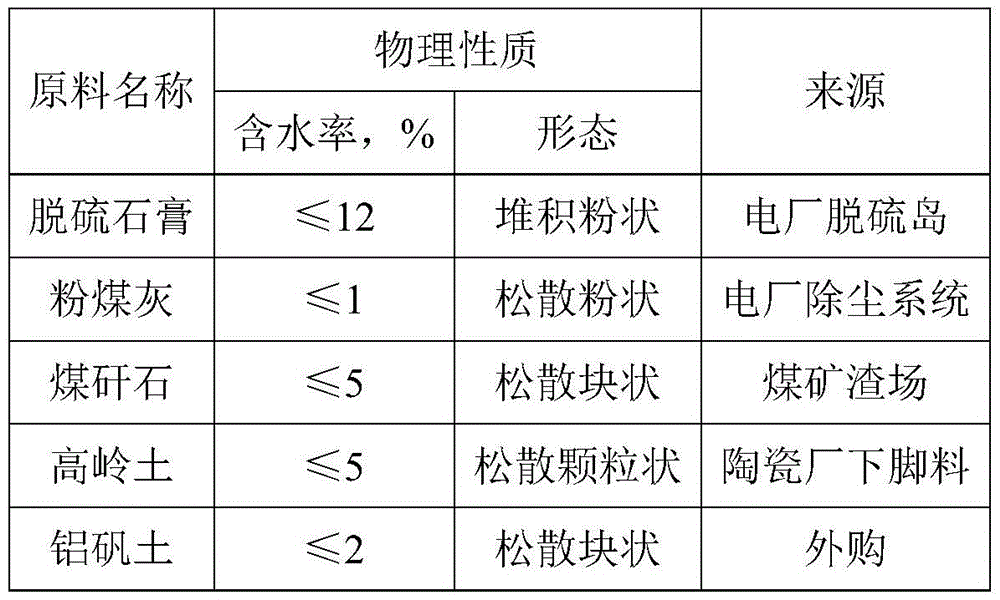

[0031] The sulphoaluminate cement clinker of this embodiment is made of admixture and the following raw materials in parts by weight: 20 parts of desulfurized gypsum, 35 parts of fly ash, 20 parts of kaolin, 10 parts of coal gangue, and 15 parts of bauxite; The admixture is composed of 20wt% potassium permanganate, 5wt% manganese dioxide and 75wt% barium sulfate, and the mass of the admixture is 0.03% of the total mass of desulfurized gypsum, fly ash, kaolin, coal gangue and bauxite.

[0032] The preparation method of the sulphoaluminate cement clinker of the present embodiment comprises the following steps:

[0033] 1) Dry the moisture of desulfurized gypsum, coal gangue and kaolin until the moisture is less than 2wt%; grind the mixture of desulfurized gypsum, fly ash, kaolin, coal gangue and bauxite, and add additional agent, pulverized until the sieve residue measured with a 0.45mm square hole sieve is 4wt%; after stirring and homogenizing, the homogenization coefficient is...

Embodiment 2

[0037] The sulphoaluminate cement clinker of this embodiment is made of admixture and the following raw materials in parts by weight: 25 parts of desulfurized gypsum, 30 parts of fly ash, 22 parts of kaolin, 8 parts of coal gangue, and 15 parts of bauxite; The admixture is composed of 25wt% potassium permanganate, 3wt% manganese dioxide and 72wt% barium sulfate, and the mass of the admixture is 0.02% of the total mass of desulfurized gypsum, fly ash, kaolin, coal gangue and bauxite.

[0038] The preparation method of the sulphoaluminate cement clinker of the present embodiment comprises the following steps:

[0039] 1) Dry the moisture of desulfurized gypsum, coal gangue and kaolin until the moisture is less than 2wt%; grind the mixture of desulfurized gypsum, fly ash, kaolin, coal gangue and bauxite, and add additional agent, pulverized until the sieve residue measured with a 0.45mm square hole sieve is 4wt%; after stirring and homogenizing, the homogenization coefficient is ...

Embodiment 3

[0043] The sulphoaluminate cement clinker of this embodiment is made of admixture and the following raw materials in parts by weight: 23 parts of desulfurized gypsum, 32 parts of fly ash, 25 parts of kaolin, 5 parts of coal gangue, and 10 parts of bauxite; The admixture is composed of 15wt% potassium permanganate, 5wt% manganese dioxide and 80wt% barium sulfate, and the mass of the admixture is 0.05% of the total mass of desulfurized gypsum, fly ash, kaolin, coal gangue and bauxite.

[0044] The preparation method of the sulphoaluminate cement clinker of the present embodiment comprises the following steps:

[0045]1) Dry the moisture of desulfurized gypsum, coal gangue and kaolin until the moisture is less than 2wt%; grind the mixture of desulfurized gypsum, fly ash, kaolin, coal gangue and bauxite, and add additional agent, pulverized until the sieve residue measured with a 0.45mm square hole sieve is 4wt%; after stirring and homogenizing, the homogenization coefficient is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com