Olefin epoxidation catalyst preparation method, catalyst and application

A catalyst, epoxidation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the modification and improvement of the morphology and structure of nano-silver particles limited effect, catalyst activity and selectivity improvement limitations, etc., to achieve the effect of improving morphology and structure, and improving selectivity and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

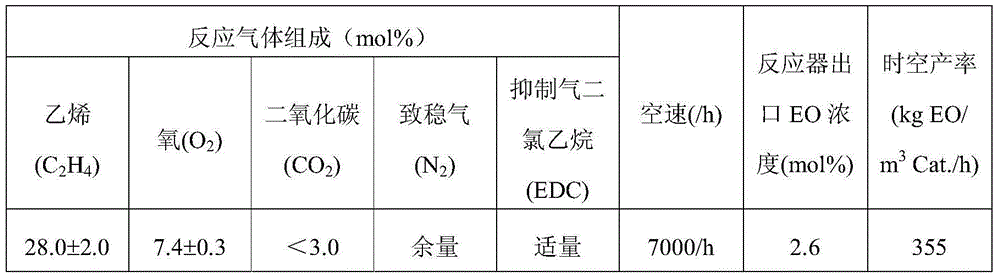

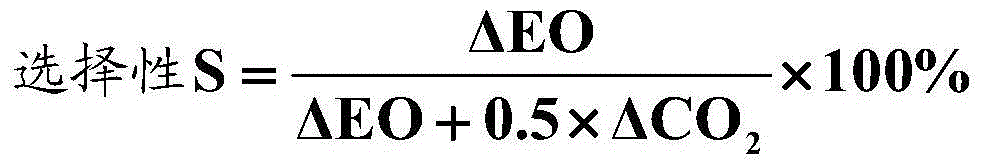

Examples

Embodiment 1

[0047] Preparation of silver catalyst carrier A:

[0048] Mix 50-500 mesh trishui A1 2 o 3 400g, fake monohydrate A1 through 200 mesh sieve 2 o 3 200g, mineralizer 10g, barium salt 3g, put into the mixer and mix evenly, transfer to the kneader, add 120 milliliters of 20wt% nitric acid aqueous solution, knead into a paste that can be extruded. Extrude into a single-hole column with an outer diameter of 8.0mm, a length of 6.0mm, and an inner diameter of 1.0mm, and dry at 80-120°C for 2 hours to reduce the free water content to below 10% by weight to obtain a green body. Then put the green body into an electric furnace, raise it from room temperature to 1300°C, and keep the temperature at this high temperature for 2 hours to obtain white α-A1 2 o 3 A sample, referred to as Support A, was used as the silver catalyst support of the present invention. The crushing strength of the above-mentioned carrier is 75N, the water absorption rate is 55%, the specific surface area is 1.2...

Embodiment 2

[0053] Add 0.05g of PVA-124 to a stirred glass flask, then add 75g of deionized water, and heat to 90°C to completely dissolve the PVA-124 to form a uniform transparent sol A1.

[0054] In another glass flask with stirring, 175 g of ethylenediamine, 70 g of ethanolamine, and 200 g of deionized water were added to obtain a mixed solution. Slowly add silver oxalate into the obtained mixed solution under stirring, keep the temperature at 10-25° C. to completely dissolve the silver oxalate, and add the amount of silver oxalate so that the final impregnating solution contains 26% by weight of silver. Add 2.5g of cesium nitrate, 0.5g of strontium acetate, and 2.25g of ammonium perrhenate, and then add deionized water to make the total mass of the solution reach 925g to prepare impregnating solution B1 for use.

[0055] Keep the temperature at 10-25°C, mix A1 and B1 and stir well. Take 250g of carrier A and put them into vacuumable containers respectively. Vacuum until the vacuum d...

Embodiment 3

[0057] Add 0.05g of PVA-124 to a stirred glass flask, then add 200g of deionized water, and heat to 90°C to completely dissolve the PVA-124 to form a uniform transparent sol. Then lower the temperature and keep it at 10-25°C, continue to add 175g of ethylenediamine and 70g of ethanolamine, and slowly add silver oxalate into the resulting mixture under stirring to completely dissolve the silver oxalate. The amount of silver oxalate added is such that the final The dipping solution contains 24% by weight of silver. Add 2.5g of cesium nitrate, 0.5g of strontium acetate, and 2.25g of ammonium perrhenate, and then add deionized water to make the total mass of the solution reach 1000g, and make an impregnation solution for use.

[0058]Take 250g of carrier A and put them into vacuumable containers respectively. Vacuum until the vacuum degree is lower than 10mmHg, put the above mixed impregnation solution into it, immerse the carrier, and keep it for 30 minutes. The excess macerati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com