Roxatidine acetate hydrochloride tablets and preparation method thereof

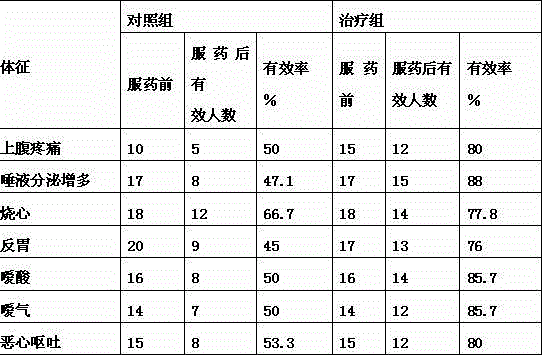

The technology of roxatidine hydrochloride acetate and filler is applied in the field of rosatidine hydrochloride acetate tablets and preparation thereof, which can solve the problems of drugs containing toxins, poor stability, side effects and the like, and achieve good tolerance , The preparation method is simple and easy, and the effect of preventing aspiration pneumonia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of roxatidine acetate hydrochloride tablet and preparation method thereof, main ingredient is roxatidine acetate hydrochloride 75mg, auxiliary material comprises filler, disintegrating agent, binding agent, lubricant composition, wherein the weight of various raw materials The percentages are 20-50% of the main material, 15-60% of the filler, 5-30% of the disintegrant, 0.1-20% of the binder and 0.01-3% of the lubricant.

[0033] The filler is one or a combination of microcrystalline cellulose, starch, pregelatinized starch, lactose, dextrin, and sucrose.

[0034] The disintegrating agent is one or more of low-substituted hydroxypropyl cellulose, sodium starch glycolate and croscarmellose sodium.

[0035] The binder is starch slurry or povidone k30 or hypromellose.

[0036] Described lubricant is the mixing of one or two in magnesium stearate, sodium lauryl sulfate.

Embodiment 2

[0038] A kind of roxatidine hydrochloride acetate tablet and preparation method thereof, the concrete steps of its preparation method are:

[0039] Step 1, select roxatidine hydrochloride acetate, filler, disintegrant, binding agent, lubricant by weight percentage, cross 80 mesh sieves respectively, for subsequent use;

[0040] Step 2. Mix the screened roxatidine hydrochloride acetate, filler and disintegrant evenly, put the mixed raw and auxiliary materials into the wet granulator, put the binder into the liquid supply tank, and turn on the Machine, adjust the parameters, open the shear flying knife at the same time, 2-5 minutes, discharge, use the swing granulator, pass through the 18-mesh nylon screen to granulate;

[0041] Step 3, place the wet granules in a fluidized bed coating machine, and dry at an inlet air temperature of 50°C;

[0042] Step 4, sizing the dry particles with a 16-mesh steel sieve;

[0043] Step 5, add lubricant, place in a three-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com