Low-calorie allium chinense bread and preparation method thereof

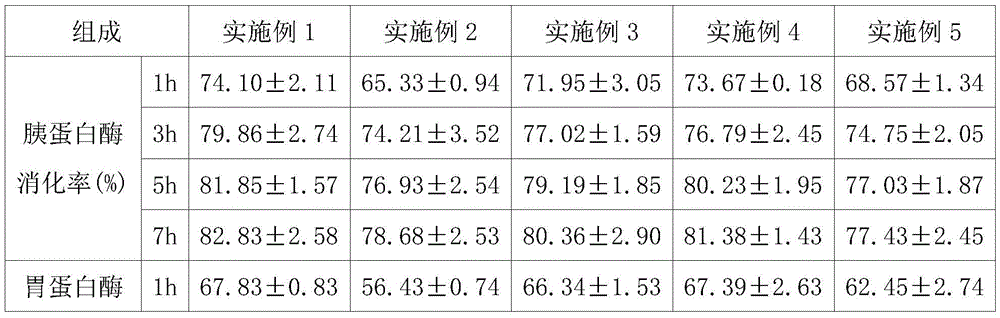

A low-calorie, bread-based technology, which is applied in dough processing, baking, baked foods with modified ingredients, etc., can solve the problems of high-calorie bread, obesity, etc., and achieve low total calories, low digestibility and unique taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A low-calorie scallion bread made from the following ingredients:

[0025] 250 grams of high-gluten bread flour, 3 grams of fennel powder, 10 grams of fennel extract, 12 grams of butter, 28 grams of sugar, 1 gram of salt, 1 gram of yeast, 1 gram of baking powder, 0.5 grams of bread improver, 150 grams of water gram.

[0026] The offspring powder is prepared according to the following method: rinse the offal dregs with running water, dry at 50° C., and grind them into fine powders of 80-100 mesh.

[0027] Described onion extract is prepared according to the following method: get the onion, add 10 times of water, beating, then adjust the pH of the slurry to be 6, and add neutral protease (enzyme activity unit) by 1% of the onion weight 147000U / g), heat preservation and enzymatic hydrolysis at 40°C for 3 hours, and the supernatant obtained by centrifugation and filtration is the xanthan extract. The content of cumin is 0.98%.

[0028] The bread is prepared as follows: ...

Embodiment 2

[0036] 293 grams of high-gluten flour, 7 grams of Chinese onion powder, 20 grams of Chinese onion extract, 10 grams of butter, 20 grams of sugar, 3 grams of salt, 3 grams of yeast, 3 grams of baking powder, 1.5 grams of bread improver, and 180 grams of water .

[0037] The offspring powder is prepared according to the following method: rinse the offal dregs with running water, dry at 60° C., and grind them into a fine powder of 80-100 mesh.

[0038] Described onion extract is prepared according to the following method: get the onion, add 15 times of water, beating, then adjust the pH of the slurry to be 7, and add neutral protease (enzyme activity unit) by 6% of the onion weight 147000U / g), heat preservation and enzymolysis at 45°C for 1 hour, and the supernatant obtained by centrifugation and filtration is the xylem extract. The content of cumin is 1.19%.

[0039] The bread is prepared as follows:

[0040] 1) Pour all the other ingredients except butter into the dough mixe...

Embodiment 3

[0047] 300 grams of high-gluten flour, 50 grams of Chinese onion powder, 50 grams of Chinese onion extract, 15 grams of butter, 25 grams of sugar, 5 grams of salt, 5 grams of yeast, 5 grams of baking powder, 3 grams of bread improver, and 200 grams of water .

[0048] The offspring powder is prepared according to the following method: rinse the offal dregs with running water, dry at 70° C., and grind them into fine powders of 80-100 mesh.

[0049] The extract of scallions is prepared according to the following method: take scallions, add 20 times of water, make a slurry, then adjust the pH of the slurry to 9, and add neutral protease according to 10% of the weight of scallions, and heat at 60°C Under the condition of heat preservation and enzymatic hydrolysis for 0.5h, the supernatant obtained by centrifugation and filtration is the xylem extract. The content of cumin is 1.07%.

[0050] The bread is prepared as follows:

[0051] 1) Pour all the other ingredients except butt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com