Gas source molecular beam epitaxy material growth method for component progressive transition layer

A technology of molecular beam epitaxy and growth method, which is applied in the field of semiconductor optoelectronic device preparation, can solve problems such as waste, long time interval, and slow switching, and achieve the effects of reducing transit time, reducing distortion, and improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

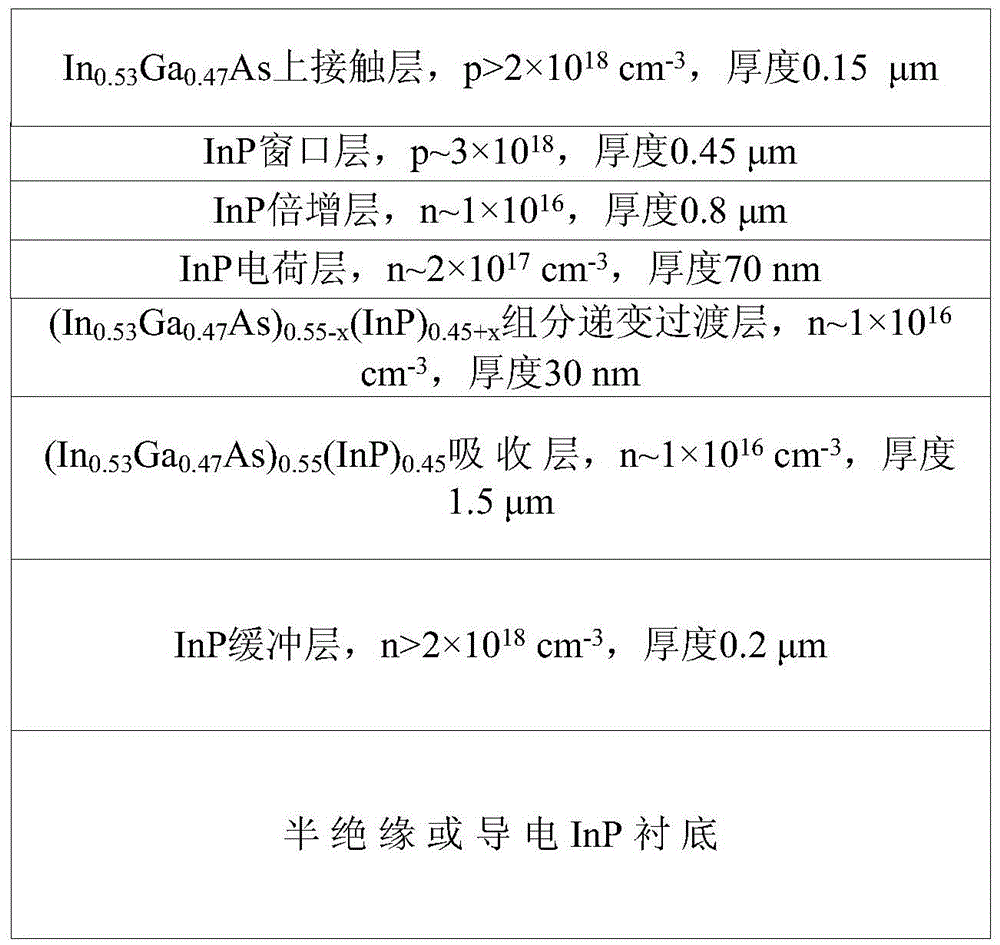

[0022] Growth of InGaAsP Avalanche Photodiode Structure Material with Cutoff Wavelength 1.25 μm on InP Substrate

[0023] (1) need to grow (In 0.53 Ga 0.47 As) 0.55 (InP) 0.45 The avalanche photodiode epitaxial material adopts the separation of the absorption region charge region and the multiplication region, and has a transition layer (SAGCM) structure. The schematic diagram is as follows figure 2 As shown, that is: InP material is used as a buffer layer and is highly doped with Si (at the same time as the lower contact layer, n>2×10 18 cm -3 ), (In 0.53 Ga 0.47 As) 0.55 (InP) 0.45 The material is used as the absorbing layer for low doping Si or no doping (n~1×10 16 cm -3 ), undoped (In 0.53 Ga 0.47 As) 0.55-x (InP) 0.45+x The composition graded layer is used as the transition layer between the absorption layer and the charge layer, and the InP with low doping Si is used as the charge layer (n~2×10 17 cm -3 ), low-doped or undoped InP material as the multipl...

Embodiment 2

[0034] Growth of InGaAs Detector Structure Materials with Cutoff Wavelength of 2.6 Microns on InP Substrate

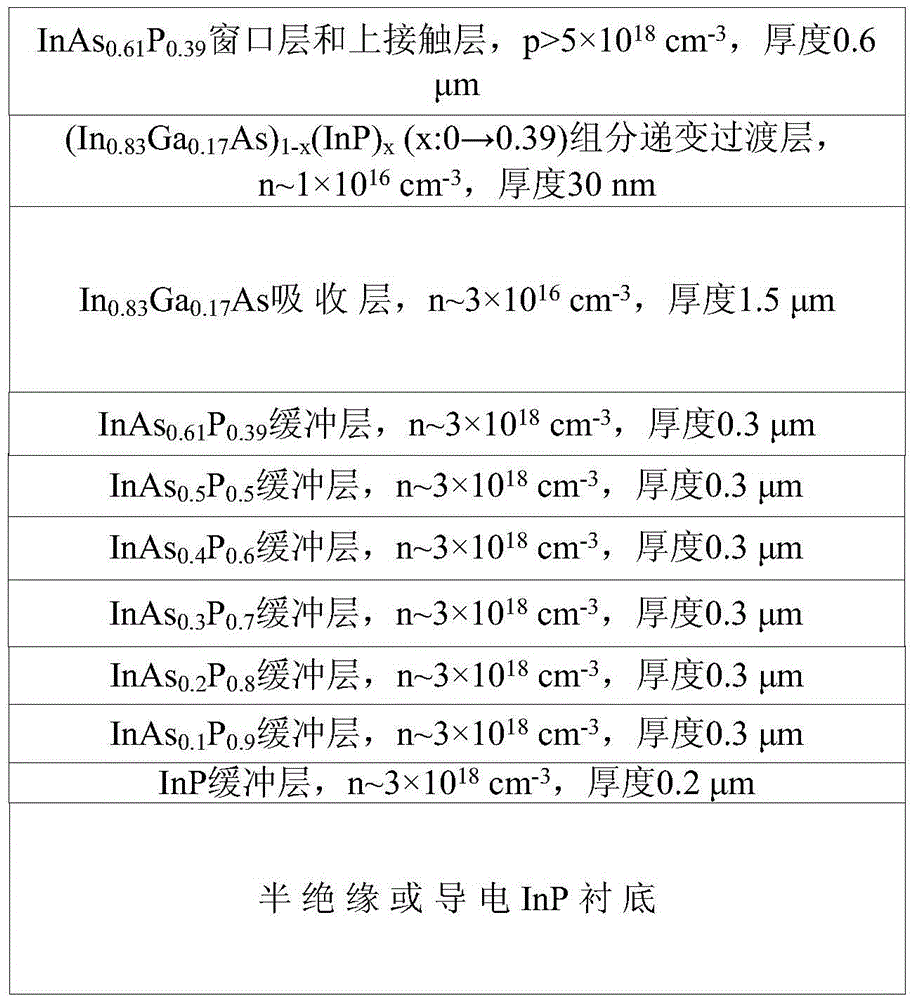

[0035] (1) The 50% cut-off wavelength at room temperature is required to be 2.6μmIn 0.83 Ga 0.17 Asp-i-n infrared photodetector structure epitaxial material, schematic diagram as shown image 3 As shown, before the formal growth, the beam source furnace temperature, substrate temperature and V group pressure values when growing lattice-matched InP and InAsP buffer layers with different As and P compositions on the InP substrate were determined by preparatory growth. growing conditions.

[0036] (2) Using the gaseous source molecular beam epitaxy method, the semi-insulating or conductive InP single crystal material is used as the substrate of the detector. After the oxide desorption treatment is performed on the Epi-ReadyInP substrate, the thickness is grown at a substrate temperature of 490°C. About 0.2μm highly doped Si n-type InP buffer layer, n~3×10 18 cm -3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com