Anti-vibration cooling wall of ground gas turbine combustion chamber

A cooling wall and combustion chamber technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of complex wall structure and difficult processing of combustion chambers, achieve high cooling efficiency, improve cooling efficiency, and prevent oscillation combustion consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

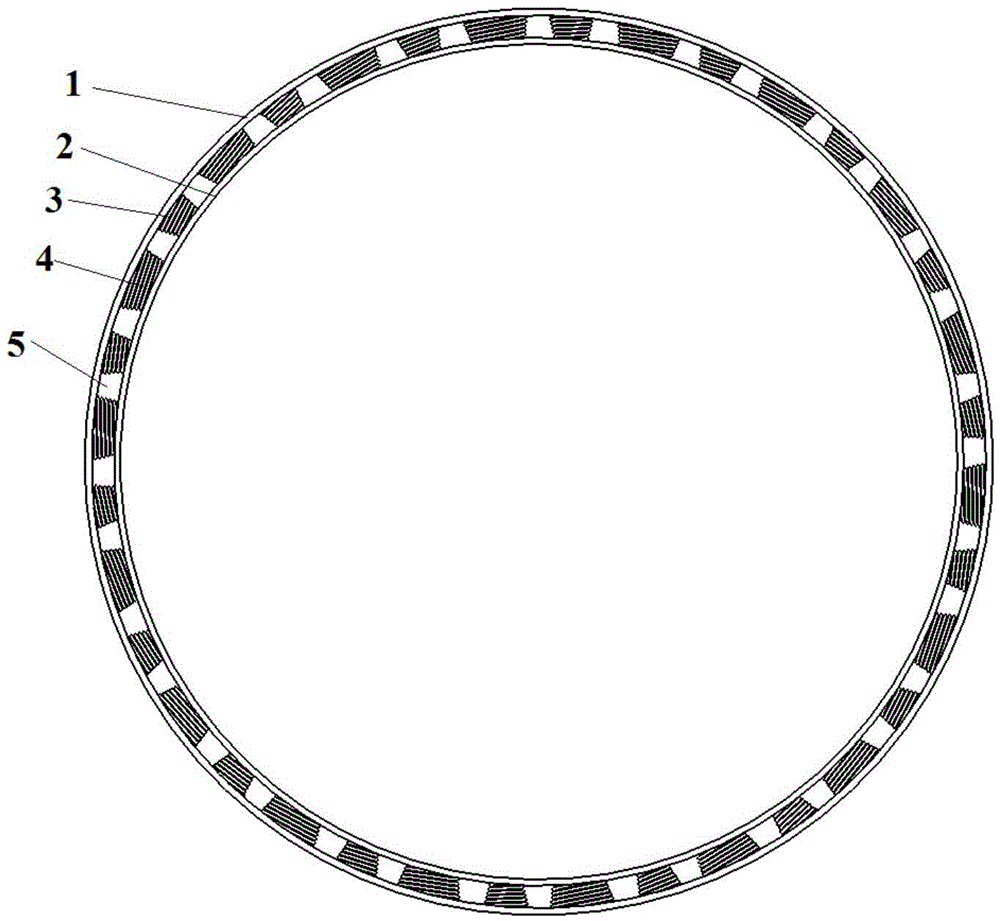

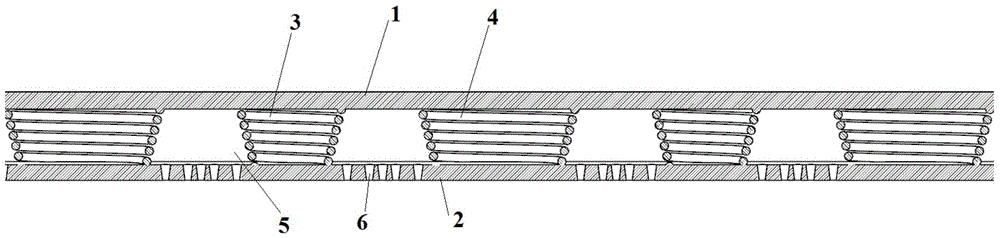

[0018] Such as figure 1 , 2 As shown, the anti-vibration cooling wall of a ground gas turbine combustion chamber in this embodiment includes an outer wall 1 and an inner wall 2, and the inner wall 2 is fixed on the outer wall 1 by a small screw spring 3 and a large screw spring 4, and the two walls A connected cavity 5 is formed between them. The inner wall 2 is provided with a plurality of air mold cooling holes 6, and the air mold cooling holes 6 communicate with the cavity 5, such as figure 2 shown. The air film holes 6 are sparsely distributed near the helical leaf springs 3 and 4, and densely distributed at positions far away from the helical leaf springs.

[0019] Such as figure 2 As shown, the end of the spiral spring steel 3 connected to the inner wall 2 has a smaller diameter of 0.6-0.7 mm; the end connected to the outer wall 1 has a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com