Vertical waste gasification smelting furnace

A gasification melting and melting furnace technology, which is applied in the field of vertical waste gasification melting furnaces, can solve the problems of low temperature, ash melting, and insufficient waste combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

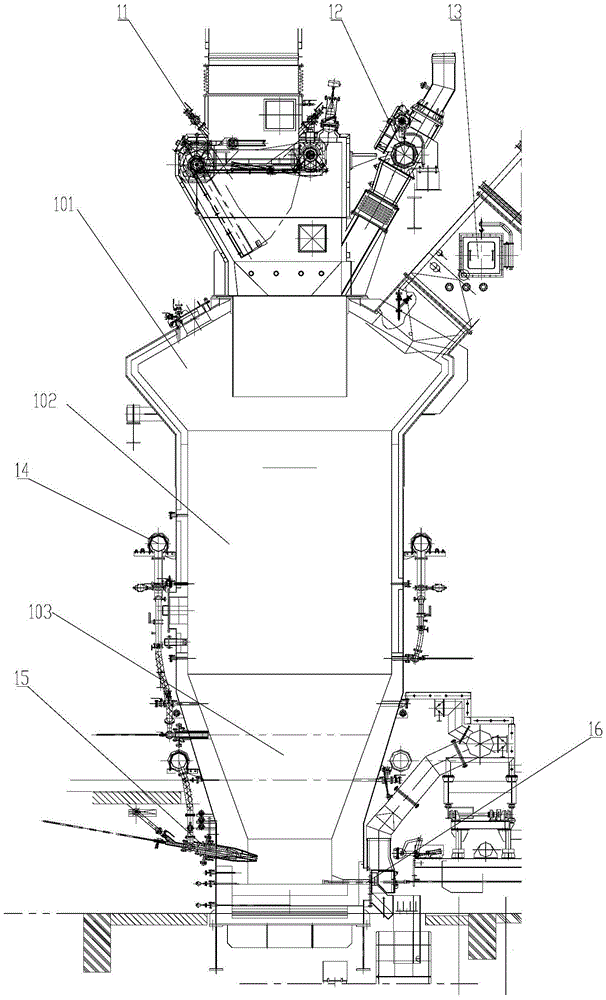

[0030] Such as figure 1 As shown, the vertical garbage gasification melting furnace in this embodiment includes a melting furnace body, and the melting furnace body includes a lug section 101, a cylindrical section 102, and a rounded table section 103 that are sequentially sealed and connected up and down. The upper end surface of the section 101 is a feeding port, and a feeding device 11 is provided directly above the feeding port, an auxiliary combustion device 12 and a gas exporting device 13 are provided on the side of the lug section, and a rich Oxygen device 14, the upper part of the rounded table section is provided with an air supply device 15, and the lower part of the rounded table section is provided with a slag outlet 16; a double sealing valve device is provided corresponding to the feeding port. Wherein, the auxiliary combustion device is used to add coal to the melting furnace body, the gas exporting device is used to export combustible gas generated during the ...

Embodiment 2

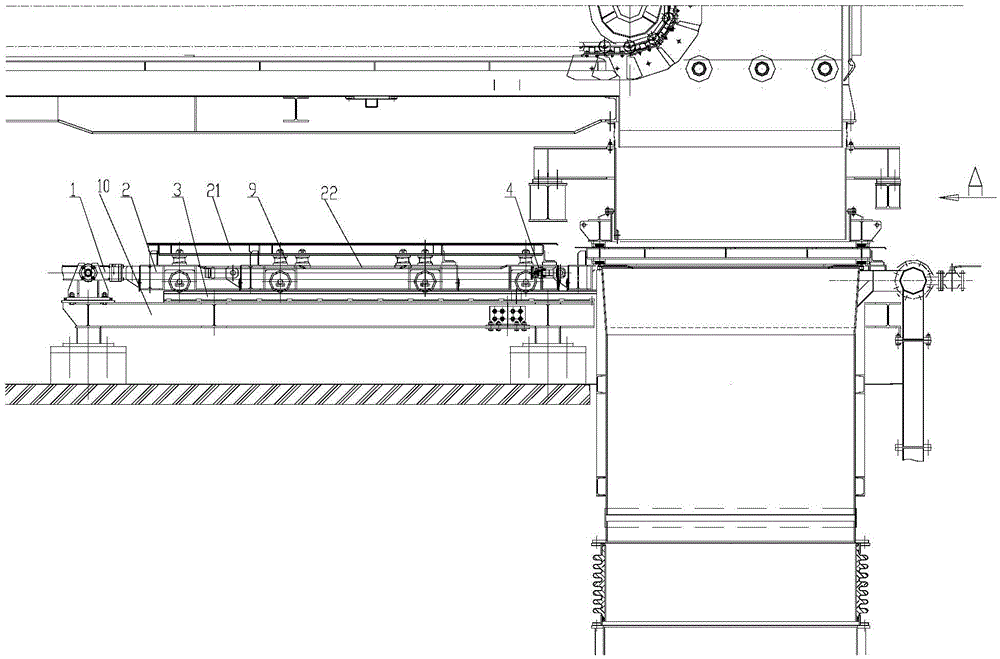

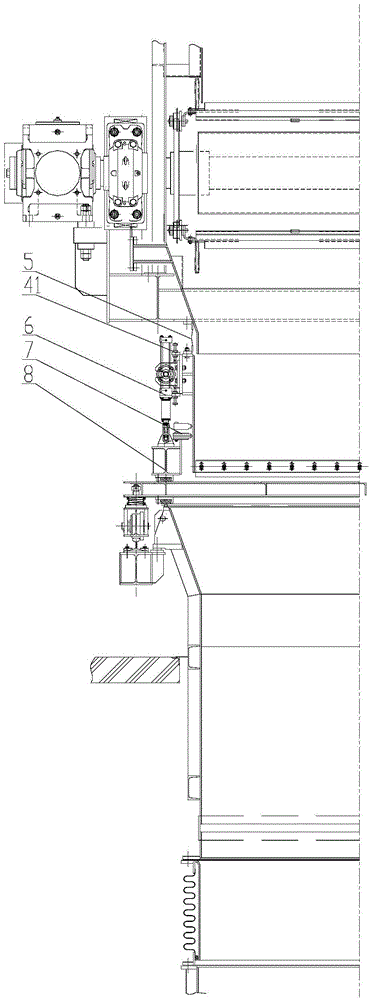

[0034] Such as figure 2 , 3 As shown, the vertical garbage gasification and melting furnace of this embodiment is based on Embodiment 1, and specifically discloses a double-sealing valve device.

[0035] The double-sealing valve device includes a traversing sealing part arranged on one side of the feeding port of the melting furnace, and a pressing down sealing part arranged above the sealing position of the feeding port for pressing the traversing sealing part tightly.

[0036] The traversing sealing part includes a horizontally arranged frame 10, the outer end of the frame 10 is provided with a traversing hydraulic cylinder 1, and a track 3 arranged inside the traversing hydraulic cylinder 1, and the track 3 is provided on the rail There is a traversing sealing car 2 adapted to the feeding port, the telescopic rod of the traversing hydraulic cylinder 1 is connected to the traversing sealing car 2, and drives the traversing sealing car 2 to move along the track 3 . The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com