Melt separation furnace reducing system for blowing oxygen and method

A melting furnace, oxygen technology, applied in furnaces, shaft furnaces, furnace types, etc., can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

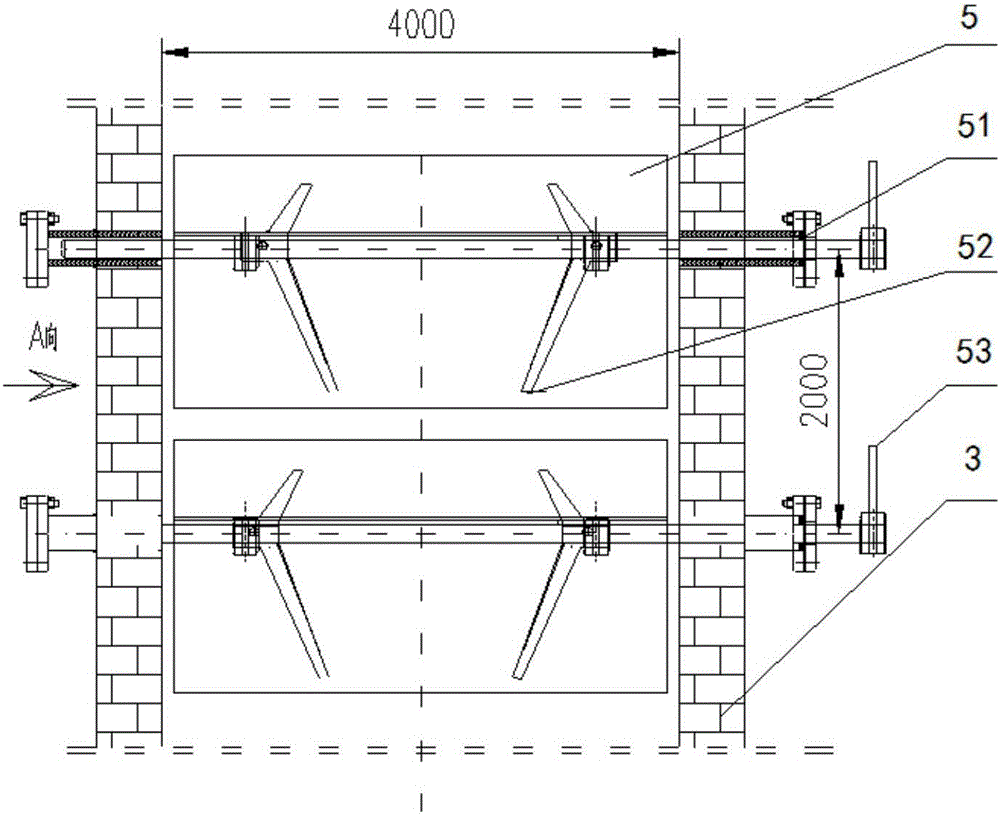

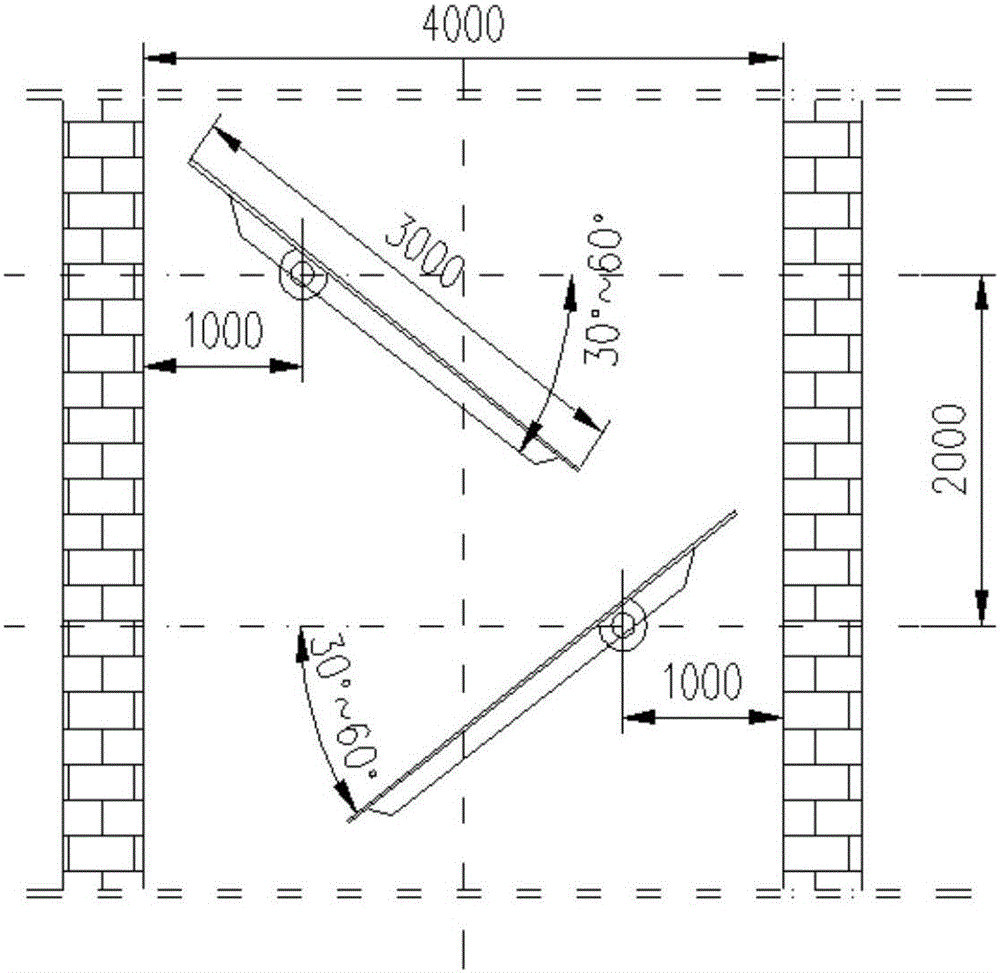

[0050] Mineral powder and a small amount of flux lime powder are put into the mineral powder hopper 1, and are sent into the direct reduction shaft furnace 3 through the speed-regulating feeder 2 at the bottom of the mineral powder hopper 1. The pulverized coal is put into the pulverized coal hopper 11, and the pulverized coal is sent into the reduction shaft furnace 3 through the speed-regulating feeder 12 at the bottom of the pulverized coal hopper 11. Mineral powder, solvent and coal powder fall on the inclined baffle plate 5 and gradually slide down. The high-temperature CO gas coming out of the melting furnace 9 enters the direct reduction shaft furnace 3 through the high-temperature flue gas pipeline 6 . The high-temperature CO gas reacts with the ore powder, and the ore powder generates direct reduced iron powder, and the iron powder enters the melting furnace 9 through the feeding port 7 . Oxygen enters the oxygen lance 8 through the oxygen pipeline 13, and burns with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com