a combined evaporator

An evaporator and combined technology, which is applied in the field of combined evaporators, can solve the problems of large space occupation and inconvenient sealing, and achieve the effects of efficient use of space, convenient installation, and increased heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

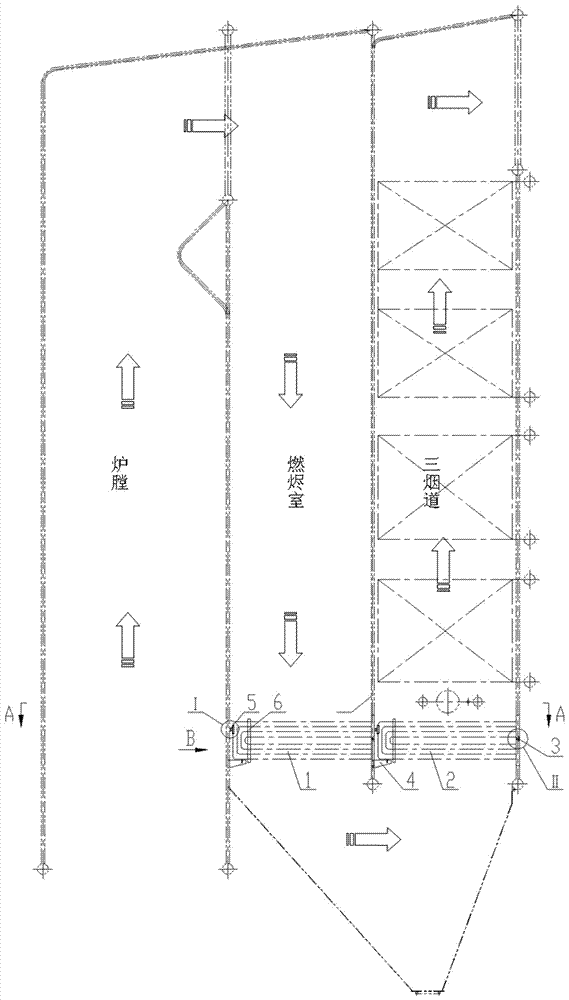

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

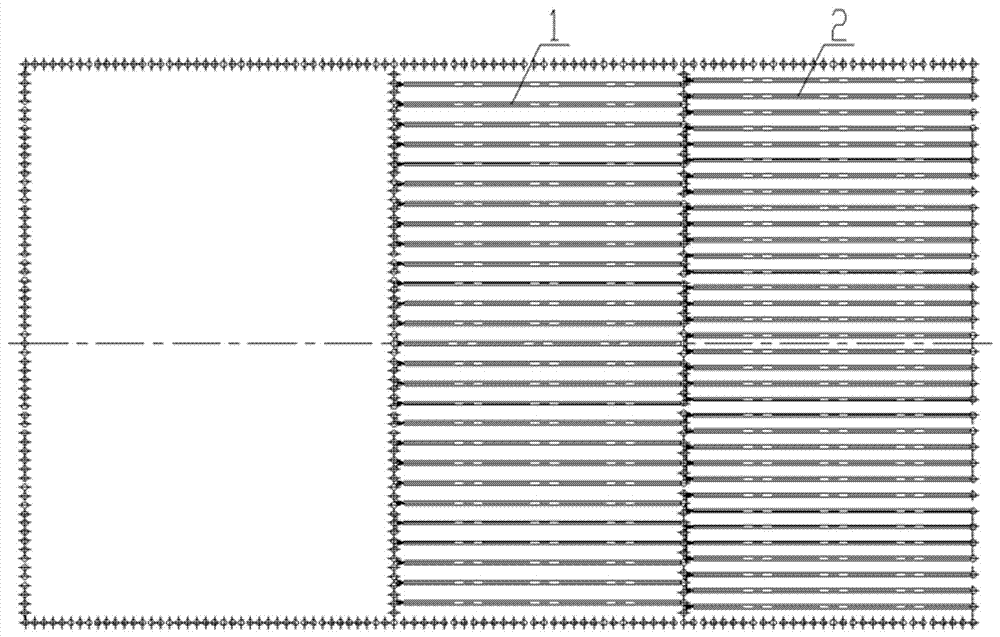

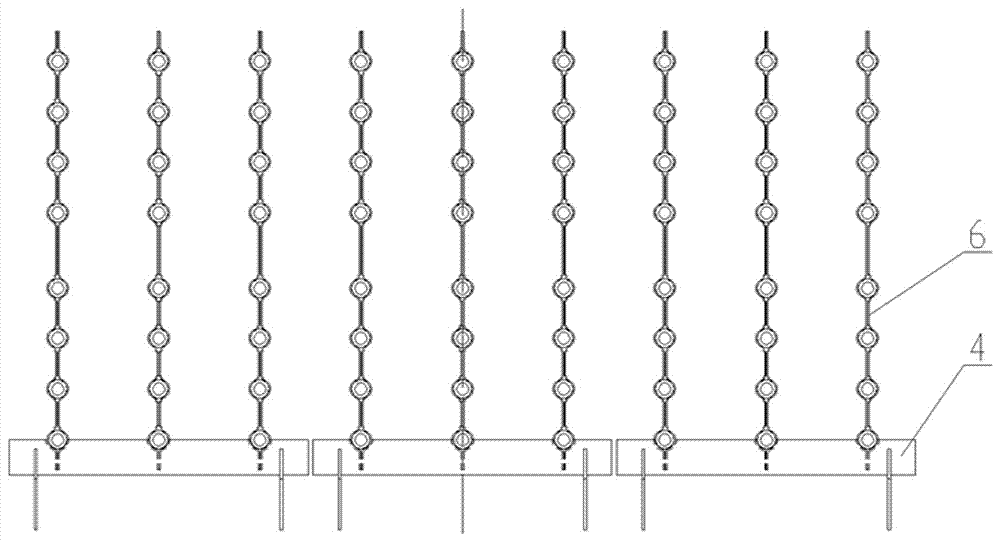

[0030] like Figure 1-5 As shown, the combined evaporator of the present invention includes a first evaporator tube bundle 1 , a second evaporator tube bundle 2 , a bracket 4 and a bracket 5 . The first evaporator tube bundle 1 is arranged at the bottom of the ember chamber, and the second evaporator tube bundle 2 is arranged at the bottom of the three flues. The first evaporator tube bundle and the second evaporator tube bundle are composed of multiple rows of parallel tube bundles. The inlet and outlet ends of the tube bundles of the first and second evaporators are directly connected to the corresponding water-cooled wall tubes, and slots are made on the water-cooled wall tubes between the inlets and outlets of the tube bundles of the first and second evaporators, and the throttling orifice plate 3 is installed. The other ends of the tube bundles of the first and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com