composite wall panel

A technology of composite wall panels and composite layers, which is applied to building components, structural elements, buildings, etc., can solve problems such as poor integrity, water seepage in construction joints, single product types and functions, etc., and achieve wall weight reduction, high cost performance, and structural The effect of integration with functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical content of the present invention will be further described below, but it is not intended to limit the essence of the present invention.

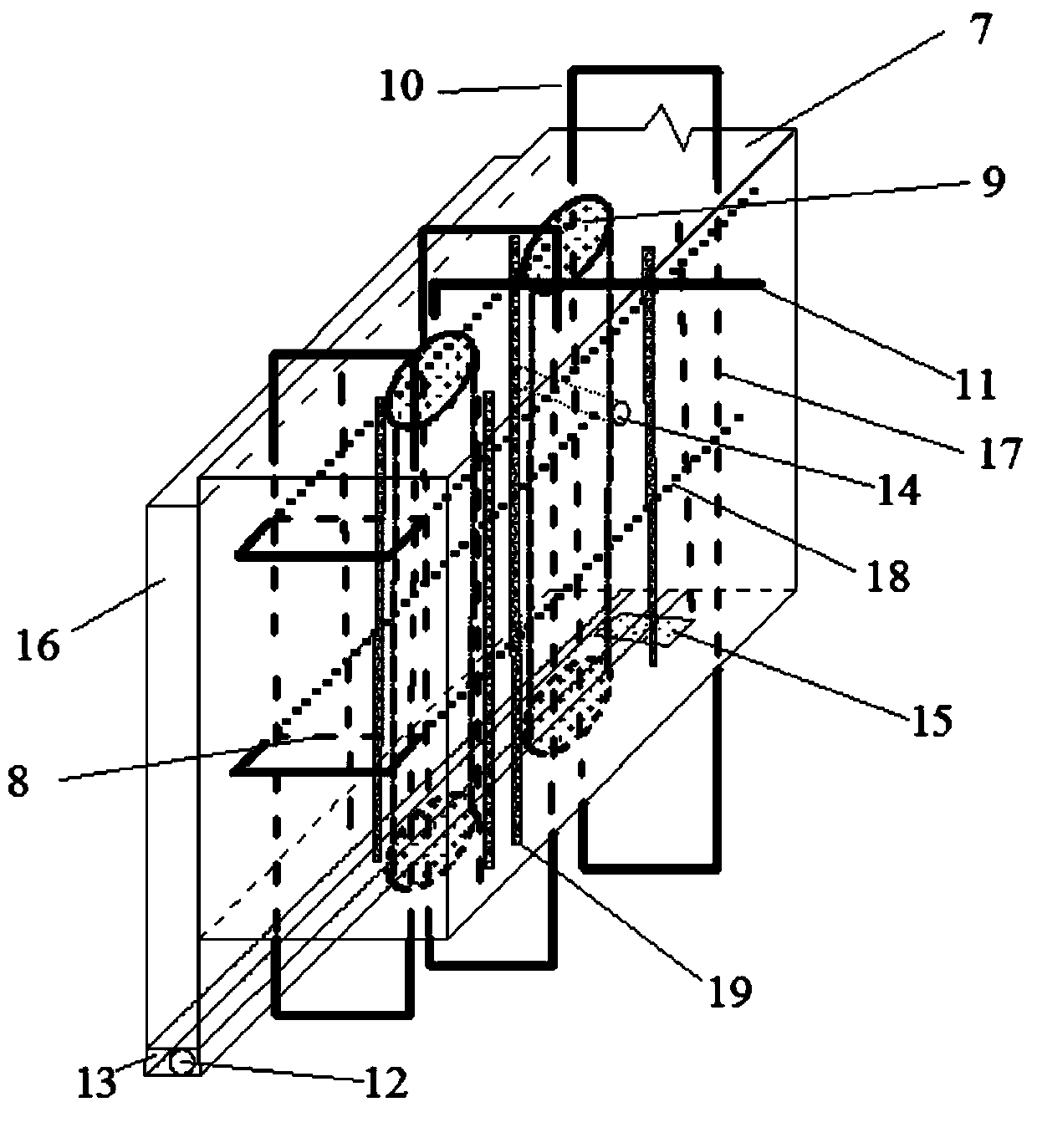

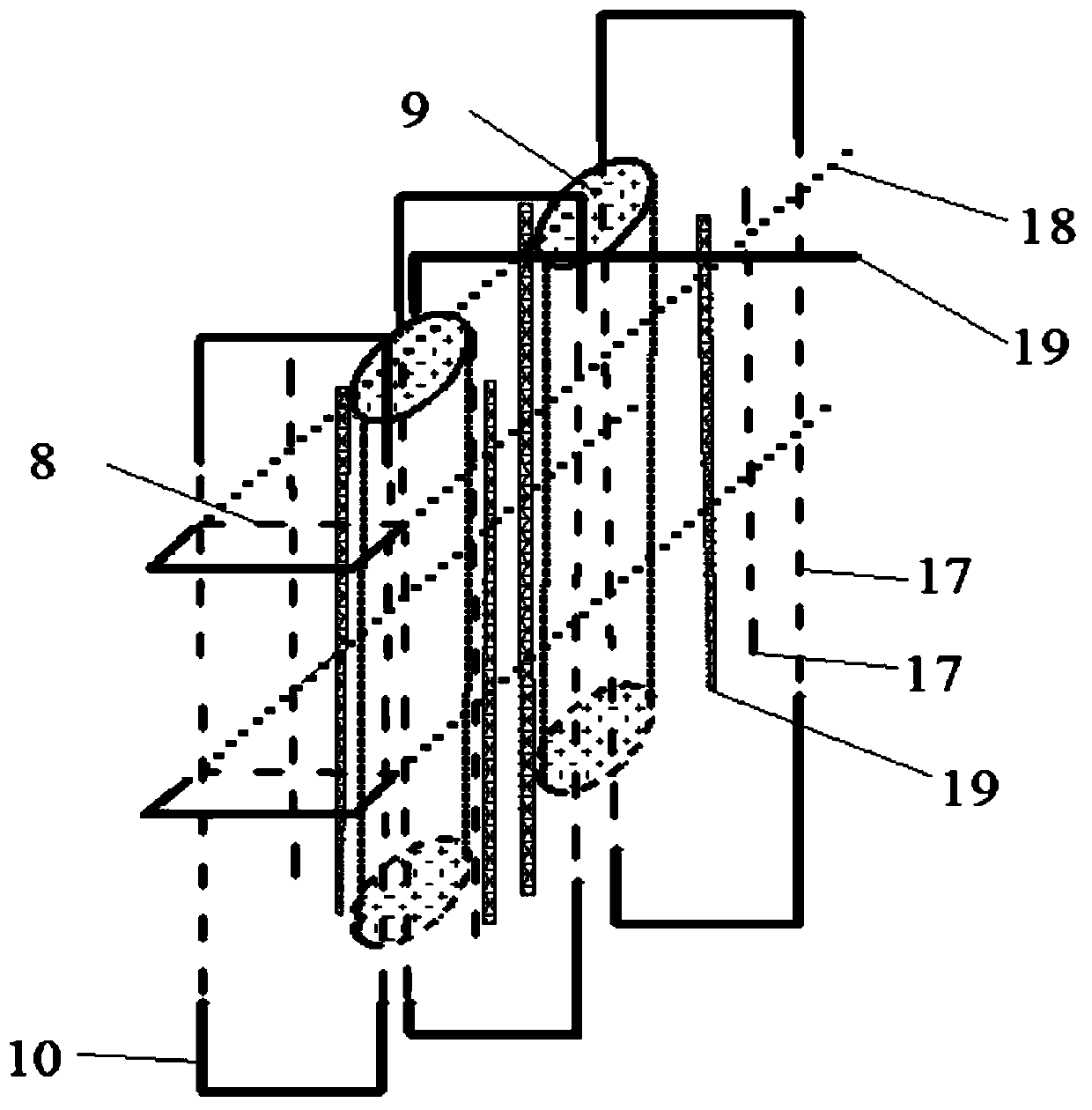

[0048] figure 1 It is the structural representation of the bamboo-steel mixed reinforcement multifunctional concrete composite wall of the embodiment of the present invention; figure 2 It is a cross-sectional schematic diagram of a bamboo-steel mixed reinforcement multifunctional concrete composite wall in an embodiment of the present invention; image 3 It is the structural representation of the bamboo-steel mixed reinforcement grid structure of the present invention; Figure 4 It is a schematic cross-sectional view of the wall functional composite layer of the present invention; Figure 5 It is one of the schematic diagrams of the anchor structure of the present invention; Figure 6 It is the second schematic diagram of the anchor structure of the present invention; Figure 7 It is the third schematic diagram of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com