Metallographic corrosive liquid used for 304L stainless steel and preparation method and corroding method thereof

A metallographic corrosion and stainless steel technology, applied in the preparation of test samples, etc., can solve the problems of unsatisfactory corrosion effect, not obvious grain boundary, and good corrosion effect, so as to adjust and optimize the production process and improve product quality , good corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A method for preparing a metallographic corrosion solution, firstly put ferric chloride into a beaker, then pour distilled water into the beaker, and finally pour concentrated hydrochloric acid into the beaker, stir evenly to fully dissolve the ferric chloride, and let stand It is configured as a metallographic etching solution for 5 minutes.

[0018] A metallographic corrosion method of 304L stainless steel, the 304L stainless steel sample is subjected to rough grinding, fine grinding, distilled water cleaning, ultrasonic cleaning, alcohol rinsing, and drying to make a sample to be tested; the sample to be tested is poured into the metallographic The corrosive solution submerged the sample to be tested for more than 2mm, corroded for 1 to 5 minutes, took out the sample and rinsed it with distilled water quickly, then rinsed it with alcohol, dried it to obtain a 304L stainless steel sample for metallographic observation, and observed it with a metallographic microscope; ...

Embodiment 1

[0020] First put 4g of ferric chloride into the beaker, then pour 50ml of distilled water into the beaker, and finally pour 20ml of concentrated hydrochloric acid into the beaker. The iron is fully dissolved and left to stand for 5 minutes to configure a metallographic corrosion solution.

[0021] The as-cast 304L stainless steel is operated according to the above corrosion method, and the metallographic structure is as follows: figure 1 shown.

Embodiment 2

[0023] First put 6.5g of ferric chloride into the beaker, then pour 50ml of distilled water into the beaker, and finally pour 10ml of concentrated hydrochloric acid into the beaker. The iron oxide is fully dissolved and left to stand for 5 minutes to configure a metallographic corrosion solution.

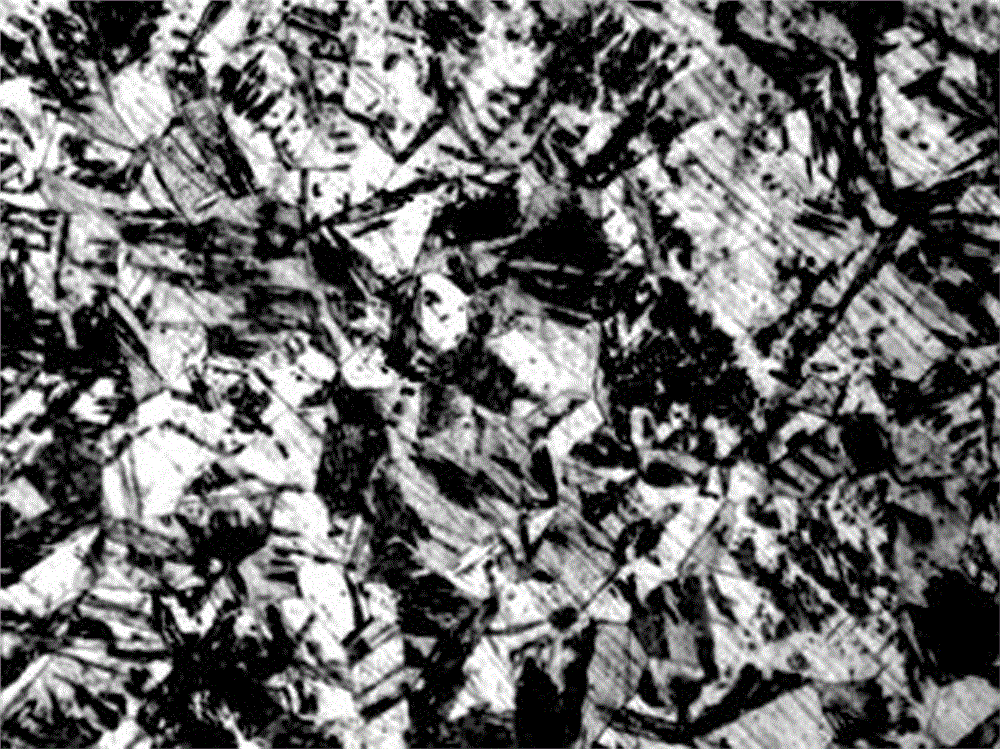

[0024] The 304L stainless steel in the cold working state is operated according to the above corrosion method, and the metallographic structure is as follows figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com