Supercritical extraction method of tea oil

A supercritical extraction and supercritical technology, which is applied in the directions of fat oil/fat production, fat oil/fat refining, and fat production, can solve the problems of unsatisfactory tea oil content, serious loss, low yield of tea oil, etc., and achieve drying efficiency. Improve and reduce the loss of nutrients, the effect of rich nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment one tea oil crude oil

[0030] Take fresh tea seeds with a moisture content of 20.6%, remove the shells, and undergo the first microwave drying and the second microwave drying. The frequency of the first microwave drying is 912MPa, the time is 3min, and the second microwave is performed after an interval of 20min. Drying, the frequency of the first microwave drying is 912MPa, the time is 1min, and the dried tea seeds are obtained. The water content of the dried tea seeds is 7.2%; the tea seeds are crushed and filtered after cold pressing, and the oil temperature at 50°C to obtain camellia oil crude oil. The tea oil crude oil was detected, the acid value was 3.2, and the peroxide value was 5.7.

Embodiment 2

[0031] The preparation of embodiment two camellia oil crude oil

[0032]Take fresh tea seeds with a water content of 20.6%. After the first microwave drying and the second microwave drying, the frequency of the first microwave drying is 912MPa, and the time is 2min. After an interval of 15min, the second microwave drying is carried out. The frequency of microwave drying is 912MPa, the time is 2min, the water content of the dried tea seeds is 7.0%, and the shells are removed to obtain tea seed kernels; the tea seed kernels are crushed, filtered after cold pressing, and the oil temperature is 50 ℃, camellia crude oil was obtained. The crude camellia oil was detected, the acid value was 3.0, and the peroxide value was 5.4.

Embodiment 3

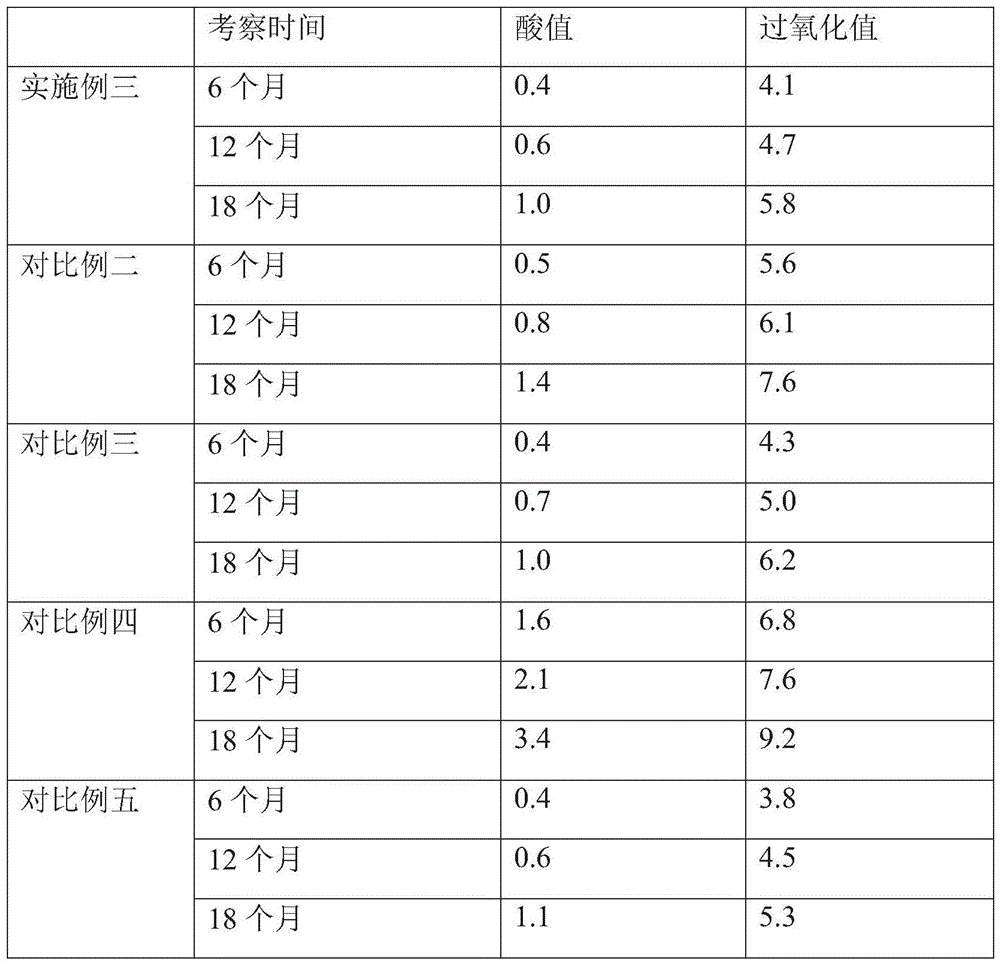

[0036] The supercritical extraction of embodiment three camellia oil

[0037] Get the tea oil crude oil 20kg that embodiment two makes, the tea oil crude oil is pumped in the extraction column that stainless steel theta ring filler is housed by extraction column top, supercritical CO 2 Enter the extraction column from the bottom of the extraction column, after the first extraction and the second extraction, collect the raffinate to obtain the finished camellia oil. The pressure of the first extraction is 9MPa, the temperature is 35℃, CO 2 The flow rate is 240L / h, the time is 40min; the pressure of the second extraction is 12MPa, the temperature is 42℃, CO 2 The flow rate is 240L / h, and the time is 20min. Based on camellia oil crude oil, the mass yield of finished camellia oil is 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com