Continuous internal heating double-barrel pyrolysis furnace for solid organic matter

A technology of solid organic matter and cracking furnace, which is applied in coking ovens, direct heating dry distillation, and preparation of liquid hydrocarbon mixtures. It can solve the problems of potential safety hazards, low processing capacity, and high labor intensity, and achieve reasonable energy utilization and high processing capacity. Great effect with low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

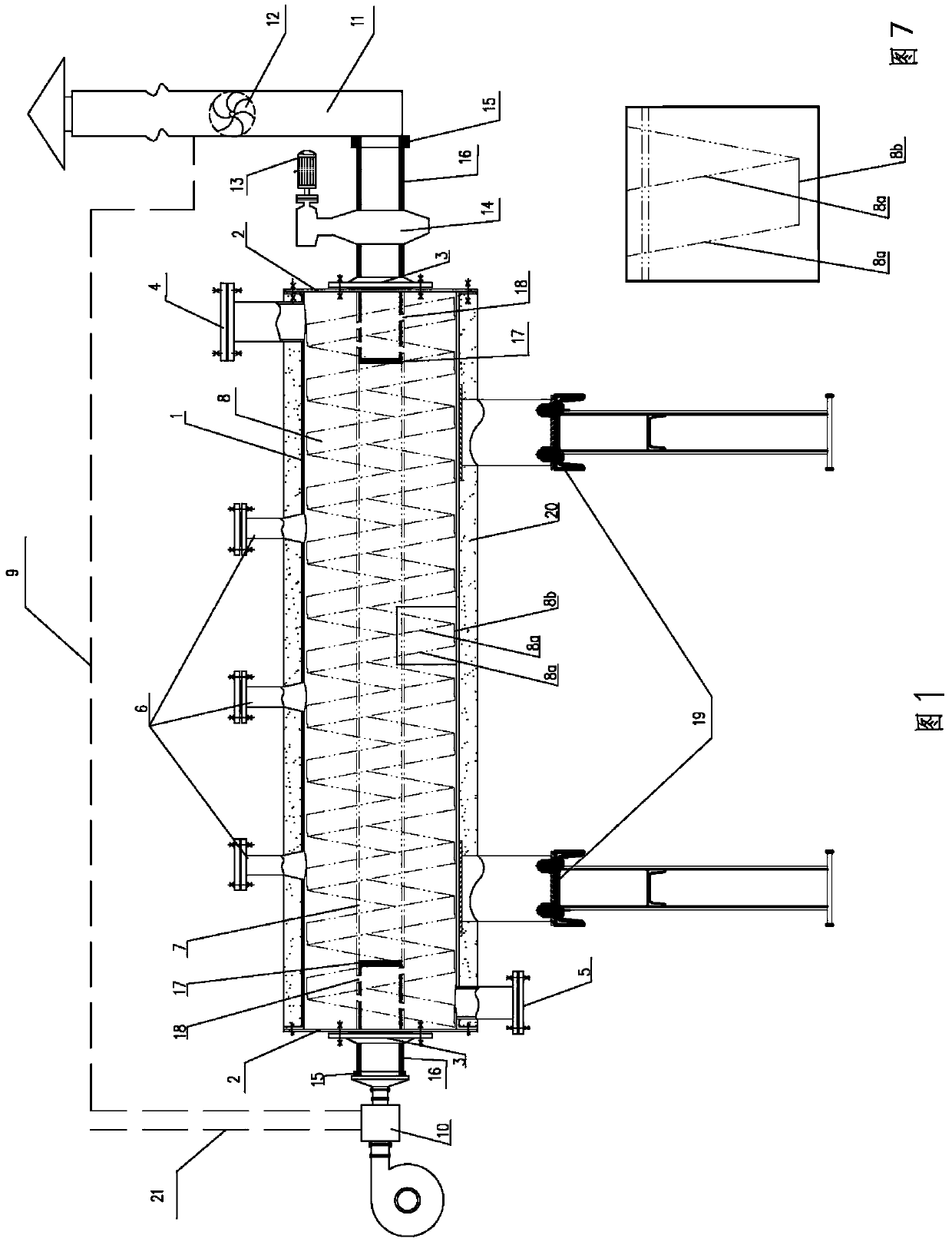

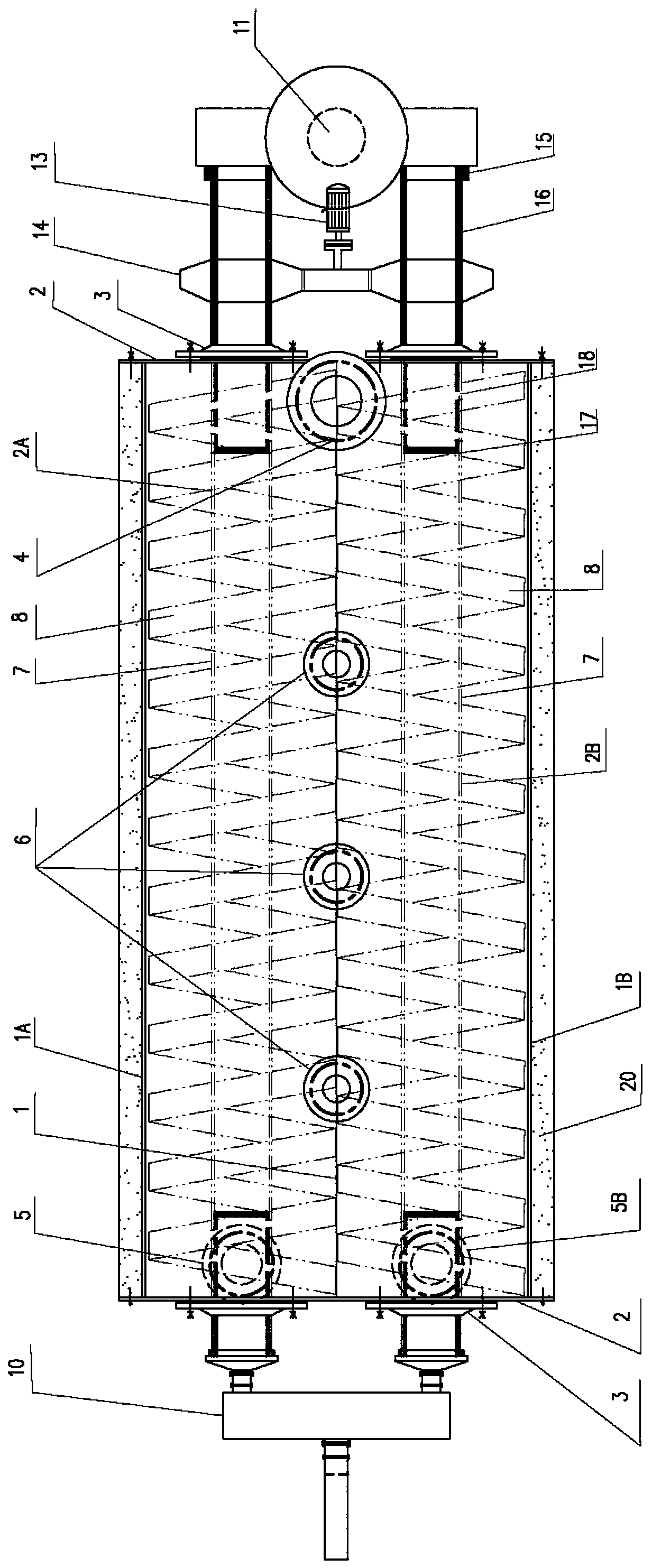

[0016] Such as Figure 1-7 , a continuous internal heat type solid organic double cylinder cracking furnace is characterized in that the cracking furnace includes double cylinders 1 supported by brackets 19 and placed horizontally, and the double cylinders 1 include left and right cylindrical cylinders arranged side by side. The cylinders (1A, 1B), the left and right cylinders (1A, 1B) have the same structure and the axes are parallel to each other, and the left and right cylinders (1A, 1B) are tangent to each other so that the two cylinders (1A, 1B ) are connected to each other, the double cylinder 1 also includes an upper surface 1C located on the upper part of the left and right cylinders (1A, 1B), and the upper surface 1C is located between the left and right cylinders (1A, 1B) , and are respectively tangent to the tops of the left and right cylinders (1A, 1B), the upper surface 1C and the left and right cylinders (1A, 1B) are enclosed to form a space, which contains three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com