High-infrared-radiance insulating heat conduction adhesive and preparing method thereof

A technology of infrared radiation, insulation and heat conduction, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of adhesive insulation, thermal conductivity and thermal radiation, etc., to improve heat dissipation Performance, improved impact resistance, improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

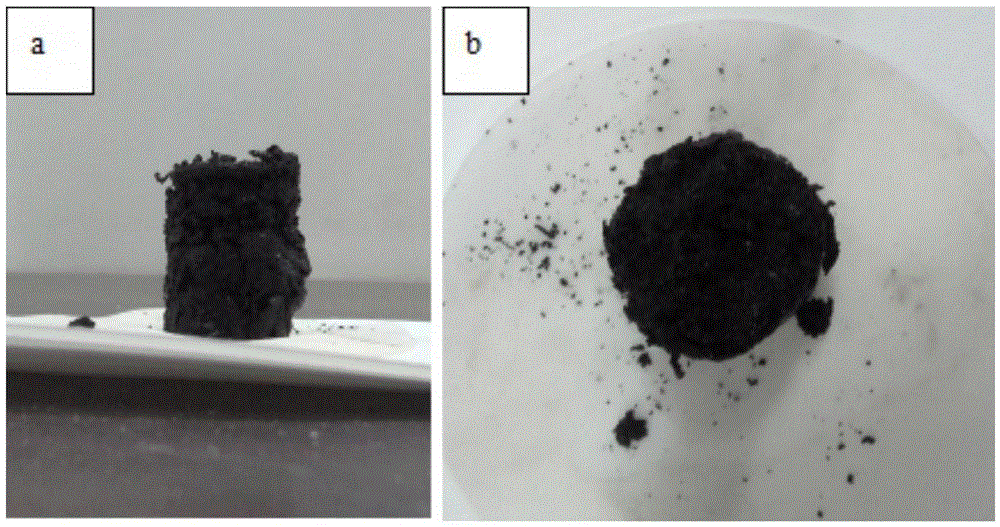

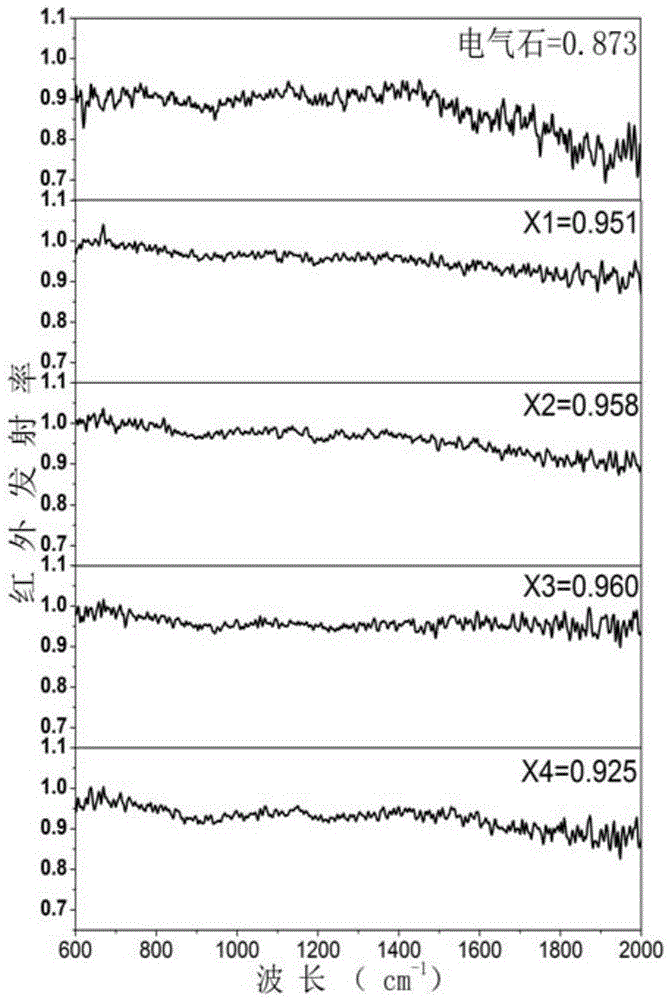

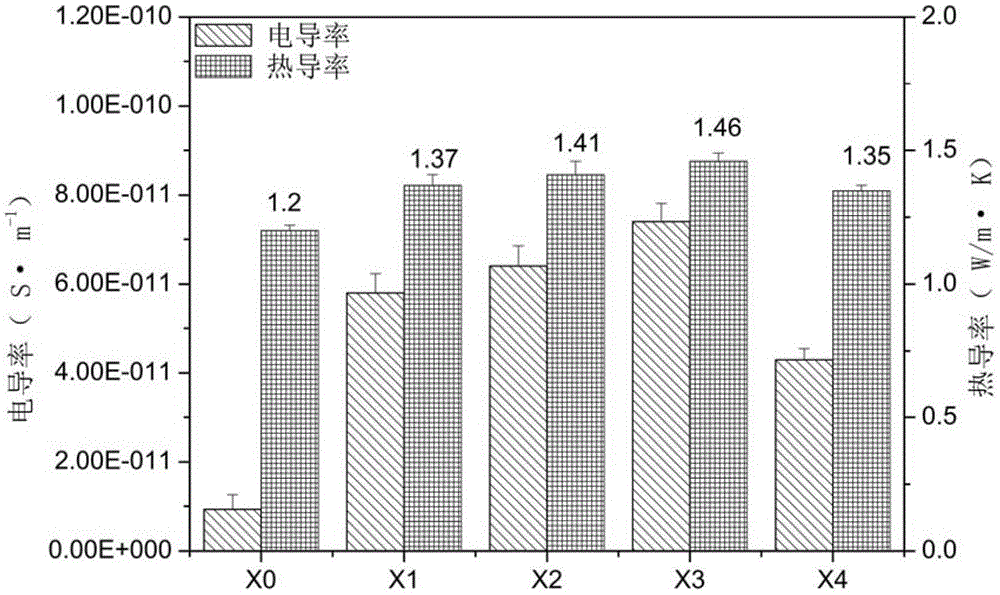

[0049] 1. Weigh 1g of graphene oxide (theoretical hydrothermal reduction can produce 0.833g of graphene), disperse it in 500mL of hydroalcoholic solution (the hydroalcoholic solution is a mixed solution of water and ethanol with a volume ratio of 1:1), and ultrasonically disperse 1h, to obtain a graphene oxide suspension; weigh 20g of tourmaline powder with a particle size of 100nm, add it to the above suspension, continue ultrasonication for 1h, and make it disperse evenly; then add 120g of anhydrous magnesium sulfate to the above mixture (Theoretical complete reaction produces 40g magnesia), while magnetic stirring, add 237mL ammoniacal liquor (28wt%, density is 0.89g / mL) drop by drop, drop time is controlled at 30min (the mole of magnesium ion and hydroxide ion in dropwise The ratio is 1:3.5), and continued to stir for 2h, after standing for 2 days, the layers were separated, 600mL of supernatant was removed, and the remaining mixture was poured into a 200mL cylindrical poly...

Embodiment 2

[0052] 1. Weigh 3g graphene oxide (theoretical hydrothermal reduction can produce 2.499g graphene), disperse it in 1500mL hydroalcoholic solution (the hydroalcoholic solution is a mixed solution of water and ethanol with a volume ratio of 1:1), and ultrasonically disperse 1h to obtain a graphene oxide suspension; weigh 35g of tourmaline powder with a particle size of 80nm, add it to the above suspension, and continue ultrasonication for 1h to make it evenly dispersed; then add 204g of anhydrous zinc chloride to the above mixture (theoretical complete reaction produces 121.5g zinc oxide), while stirring, add dropwise 2600mL sodium hydroxide solution (concentration is 50mg / mL), and the time of dropping is controlled at 60min (the mol ratio of magnesium ion and hydroxide ion in dropping 1:3.25), and continued to stir for 2 hours, separated after 3 days, removed 3970mL of supernatant, poured the remaining mixture into 200mL cylindrical polytetrafluoroethylene into a hydrothermal ke...

Embodiment 3

[0055] 1. Weigh 2g graphene oxide (theoretical hydrothermal reduction can produce 1.666g graphene), disperse it in 1000mL hydroalcoholic solution (the hydroalcoholic solution is a mixed solution of water and ethanol with a volume ratio of 1:1), and ultrasonically disperse 1h, obtain graphene oxide suspension; Take 40g particle diameter and be 90nm tourmaline powder, join in above-mentioned suspension, continue ultrasonication 1h, make it disperse evenly; Add 101.5g magnesium chloride hexahydrate and 68g of anhydrous zinc chloride (theoretical complete reaction produces 40.5g zinc oxide and 20g magnesium oxide), while magnetically stirring, add 2800mL potassium hydroxide solution (concentration is 50mg / mL) dropwise, and the dropping time is controlled at 40min (dropping Add metal ions (magnesium ions, zinc ions) and hydroxide ions in a molar ratio of 1:2.5), and continue to stir for 1h, after standing for 4 days, separate layers, remove 3670mL supernatant; pour the remaining mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com