Method for preparing superhydrophobic coating layer through composite of inorganic nano-particles with different average particle sizes

A technology of inorganic nano-particles and super-hydrophobic coatings, applied in the field of self-cleaning materials and new materials, can solve the problems of reduced application range, high cost, complex process, etc., achieve good application prospects, simplify production industry and production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

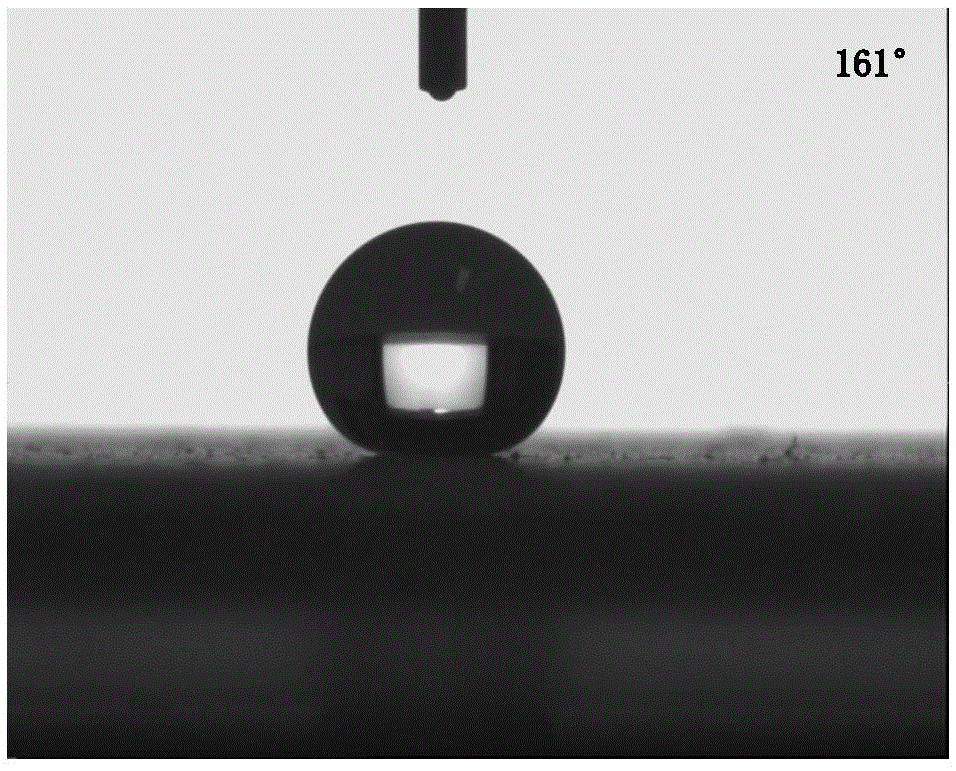

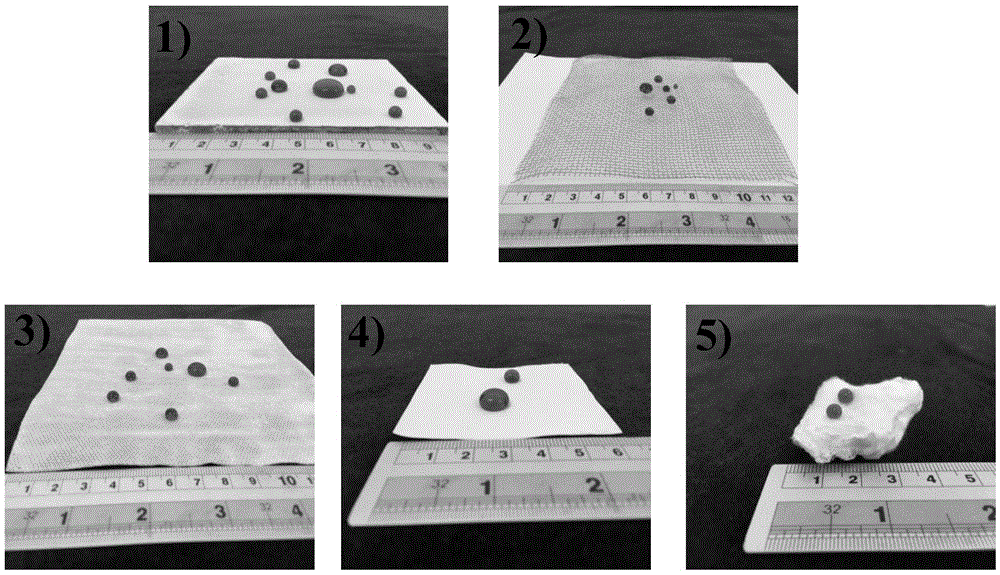

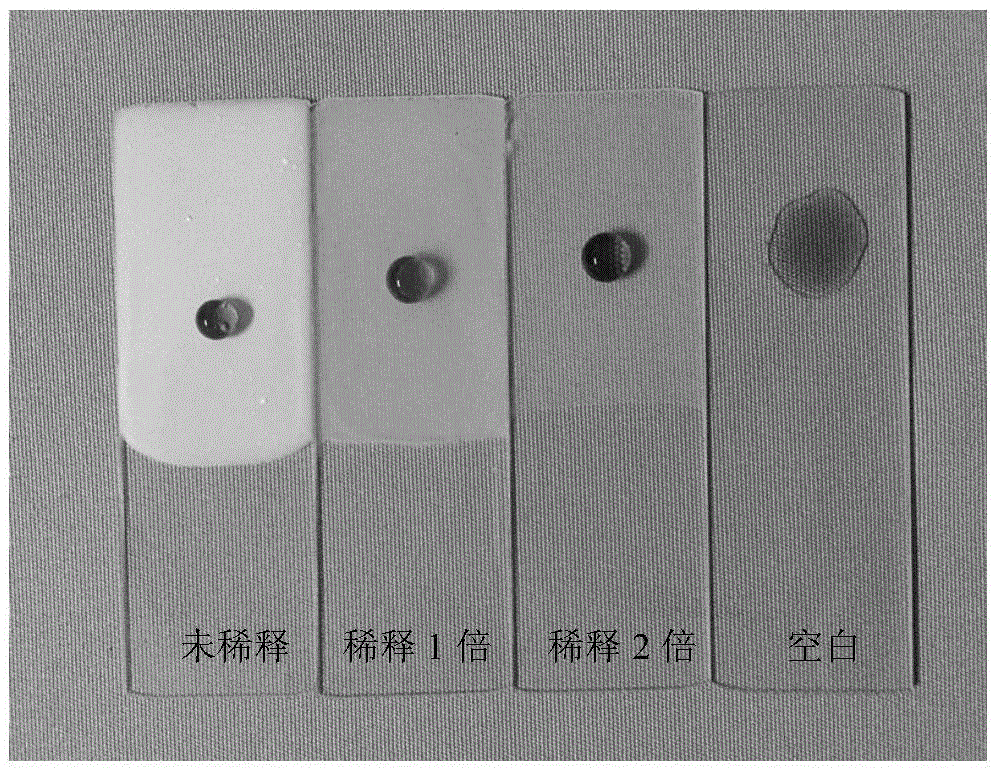

[0031] This embodiment is a method for preparing a superhydrophobic coating by compounding inorganic nanoparticles with different average particle diameters, including the following steps: take 0.5g of SiO with an average particle diameter of 100nm 2 Nanoparticles were dispersed in 50mL of absolute ethanol, ultrasonically dispersed for 30min, taken out, and magnetically stirred at 5000rpm for 30min to obtain SiO with an average particle size of 200nm 2 Uniform dispersion A; take 1.5g of SiO with an average particle size of 20nm 2 Nanoparticles were dispersed in 50mL of absolute ethanol, ultrasonically dispersed for 30min, taken out, and magnetically stirred at 5000rpm for 30min to obtain SiO with a particle size of 30nm 2 Uniform dispersion B; take 0.5g of SiO with an average particle size of 5nm 2 Nanoparticles were dispersed in 50mL of absolute ethanol, ultrasonically dispersed for 30min, taken out, and magnetically stirred at 5000rpm for 30min to obtain SiO with a particle...

Embodiment 2

[0033] This embodiment is a method for preparing a superhydrophobic coating by compounding inorganic nanoparticles with different average particle diameters, comprising the following steps: taking 0.5g of TiO with an average particle diameter of 300nm 2Nanoparticles were dispersed in 50mL of absolute ethanol, ultrasonically dispersed for 30min, taken out, and magnetically stirred at 5000rpm for 30min to obtain TiO with an average particle size of 300nm 2 Uniform dispersion A; take 1.5g of TiO with an average particle size of 50nm 2 Nanoparticles were dispersed in 50mL of absolute ethanol, ultrasonically dispersed for 30min, taken out, and magnetically stirred at 5000rpm for 30min to obtain TiO with a particle size of 50nm 2 Uniform dispersion B; take 0.5g of TiO with an average particle size of 10nm 2 Nanoparticles were dispersed in 50mL of absolute ethanol, ultrasonically dispersed for 30min, taken out, and magnetically stirred at 5000rpm for 30min to obtain TiO with a parti...

Embodiment 3

[0035] This embodiment is a method for preparing a superhydrophobic coating by compounding inorganic nanoparticles with different average particle sizes, including the following steps: take 0.5g of TiO with an average particle size of 200nm 2 Nanoparticles were dispersed in 50mL of absolute ethanol, ultrasonically dispersed for 30min, taken out, and magnetically stirred at 5000rpm for 30min to obtain TiO with an average particle size of 200nm 2 Uniform dispersion A; take 2.5g of TiO with an average particle size of 30nm 2 Nanoparticles were dispersed in 50mL of absolute ethanol, ultrasonically dispersed for 30min, taken out, and magnetically stirred at 5000rpm for 30min to obtain TiO with a particle size of 30nm 2 Uniform dispersion B; take 0.5g of TiO with an average particle size of 10nm 2 Nanoparticles were dispersed in 50mL of absolute ethanol, ultrasonically dispersed for 30min, taken out, and magnetically stirred at 5000rpm for 30min to obtain SiO with a particle size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com