Radiation-resistant ABS (acrylonitrile-butadiene-styrene)-based composite shoe material and preparation method thereof

A radiation-resistant and shoe material technology, which is applied in the field of shoe materials, can solve problems such as unusable and non-radiation-resistant properties, and achieve the effects of improving bonding force, excellent radiation-resistant performance, and good radiation-resistant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

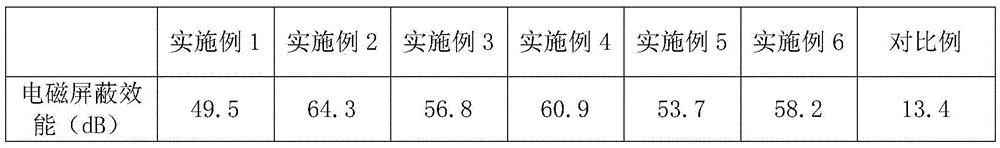

Examples

Embodiment 1

[0027] A radiation-resistant ABS-based composite shoe material, made of the following components in parts by weight: 40 parts of ABS, 0.6 parts of organotin stabilizer, 1.8 parts of polyethylene wax, 2.7 parts of DBP, and phosphite antioxidant 0.7 parts, 15 parts of light calcium carbonate, 5.6 parts of ABS-g-MAH, 10761.2 parts of antioxidant, 3.5 parts of antimony flame retardant, 14.5 parts of stainless steel fiber, and 10 parts of methyl vinyl phenyl silicone rubber.

[0028] The steps of its preparation method are as follows:

[0029] (1) dissolving stearic acid in dehydrated alcohol and dispersing evenly to make mass fraction is 10% stearic acid solution, stainless steel fiber is added in this stearic acid solution and stirred, the weight ratio of stainless steel fiber and stearic acid is 48:1, after 10 minutes, move to a constant temperature water bath at 80°C and continue to stir for 30 minutes, filter after discharge, and then place in an oven to dry to constant weight...

Embodiment 2

[0033] A radiation-resistant ABS-based composite shoe material, made of the following components in parts by weight: 50 parts of ABS, 0.8 parts of organic tin stabilizer, 1.4 parts of polyethylene wax, 2.1 parts of DBP, and phosphite antioxidant 0.5 parts, 14 parts of light calcium carbonate, 5.2 parts of ABS-g-MAH, 10761 parts of antioxidant, 4.5 parts of antimony flame retardant, 13 parts of stainless steel fiber, and 9 parts of methyl vinyl phenyl silicone rubber.

[0034] The steps of its preparation method are as follows:

[0035] (1) dissolving stearic acid in dehydrated alcohol and dispersing evenly to make mass fraction is 10% stearic acid solution, stainless steel fiber is added in this stearic acid solution and stirred, the weight ratio of stainless steel fiber and stearic acid is 48:1, after 10 minutes, move to a constant temperature water bath at 80°C and continue to stir for 30 minutes, filter after discharge, and then place in an oven to dry to constant weight to...

Embodiment 3

[0039] A radiation-resistant ABS-based composite shoe material, made of the following components in parts by weight: 52 parts of ABS, 1 part of organic tin stabilizer, 1.2 parts of polyethylene wax, 2.5 parts of DBP, and phosphite antioxidant 0.8 parts, 17 parts of bamboo charcoal powder, 5.5 parts of ABS-g-MAH, 10761.5 parts of antioxidant, 3 parts of antimony flame retardant, 15 parts of stainless steel fiber, 9.5 parts of methyl vinyl phenyl silicone rubber.

[0040] The steps of its preparation method are as follows:

[0041] (1) dissolving stearic acid in dehydrated alcohol and dispersing evenly to make mass fraction is 10% stearic acid solution, stainless steel fiber is added in this stearic acid solution and stirred, the weight ratio of stainless steel fiber and stearic acid is 48:1, after 10 minutes, move to a constant temperature water bath at 80°C and continue to stir for 30 minutes, filter after discharge, and then place in an oven to dry to constant weight to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com