Preparing method of polyadipic acid butanediol ester-terminal hydroxyl multiwalled carbon nanotube composite film

A technology of polybutylene adipate and multi-walled carbon nanotubes, which is applied in the field of preparation of polybutylene adipate-hydroxyl-terminated multi-walled carbon nanotubes composite films, can solve the problem of slow crystallization speed, poor It can effectively realize the control of PBA crystal form and the poor hardness of PBA.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

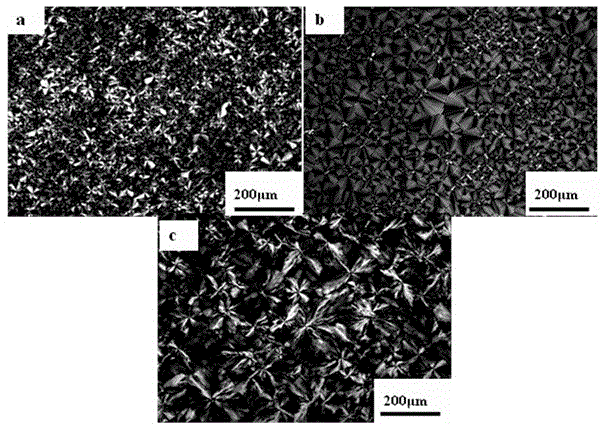

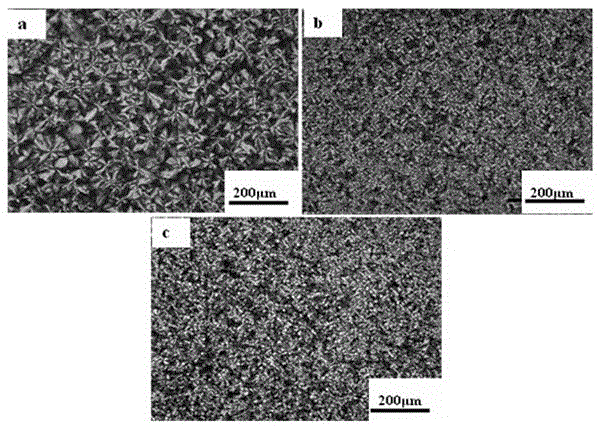

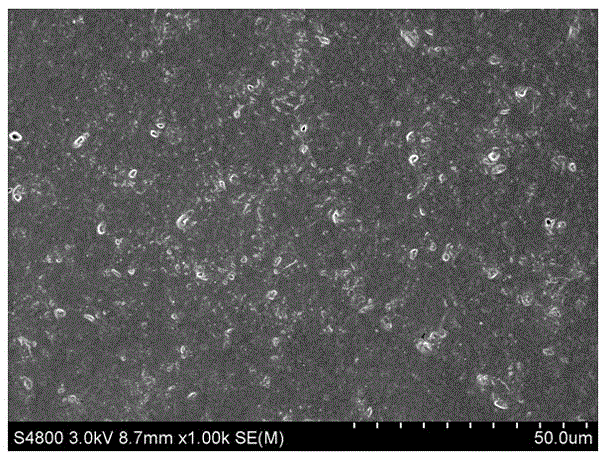

Embodiment 1

[0024] A preparation method of degradable polybutylene adipate-terminated hydroxyl multi-walled carbon nanotube composite film, comprising the following steps:

[0025] 1) Weigh PBA=0.5g, put it in a clean 10ml volumetric flask, and add in duplicate, chloroform, a good solvent for PBA, to 10ml, and place it on a magnetic stirrer at room temperature for 2 hours to fully dissolve the PBA. ;

[0026] 2) Weigh 0.0005g and 0.001g of vacuum-dried MWCNTs-OH respectively, put them in two 10ml volumetric flasks, and dilute to 10ml with chloroform, and stir the obtained MWCNTs-OH chloroform solution on a constant temperature magnetic stirrer 30min, and then ultrasonically disperse in an ultrasonic instrument at room temperature for 1h to obtain a uniformly dispersed MWCNTs-OH trichloromethane suspension;

[0027] 3) Blend the prepared PBA solution and MWCNTs-OH solution, stir on a magnetic stirrer at room temperature for 30 minutes, and then ultrasonically disperse at room temperature ...

Embodiment 2

[0030] A preparation method of degradable polybutylene adipate-terminated hydroxyl multi-walled carbon nanotube functional composite film material, comprising the following steps:

[0031] 1) Weigh PBA=0.5g, put it in a clean 10ml volumetric flask, and add in duplicate, chloroform, a good solvent for PBA, to 10ml, and place it on a magnetic stirrer at room temperature for 3 hours to fully dissolve the PBA. ;

[0032] 2) Weigh 0.0005g and 0.001g of vacuum-dried MWCNTs-OH respectively, put them in two 10ml volumetric flasks, and dilute to 10ml with chloroform, and stir the obtained MWCNTs-OH chloroform solution on a constant temperature magnetic stirrer 30min, and then ultrasonically disperse in an ultrasonic instrument at room temperature for 1h to obtain a uniformly dispersed MWCNTs-OH trichloromethane suspension;

[0033] 3) Blend the prepared PBA solution and MWCNTs-OH solution, stir on a magnetic stirrer at room temperature for 30 minutes, and then ultrasonically disperse ...

Embodiment 3

[0036] A preparation method of degradable polybutylene adipate-terminated hydroxyl multi-walled carbon nanotube functional composite film material, comprising the following steps:

[0037] 1) Weigh PBA=0.5g, put it in a clean 10ml volumetric flask, and add the good solvent chloroform of PBA in duplicate, set the volume to 10ml, put it on a magnetic stirrer at room temperature and magnetically stir for 2.5h, so that the PBA is fully dissolve;

[0038] 2) Weigh 0.0005g and 0.001g of vacuum-dried MWCNTs-OH respectively, put them in two 10ml volumetric flasks, and dilute to 10ml with chloroform, and stir the obtained MWCNTs-OH chloroform solution on a constant temperature magnetic stirrer 30min, and then ultrasonically disperse in an ultrasonic instrument at room temperature for 1h to obtain a uniformly dispersed MWCNTs-OH trichloromethane suspension.

[0039] 3) Blend the prepared PBA solution and MWCNTs-OH solution, stir on a magnetic stirrer at room temperature for 30 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com