Preparation method of rigid structure reinforced phenolic aerogel heat shielding material

A rigid structure, aerogel technology, applied in the field of composite materials, can solve the problems of low mechanical properties of phenolic aerogel, and achieve the effect of meeting design requirements, low operating site requirements, and strong dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

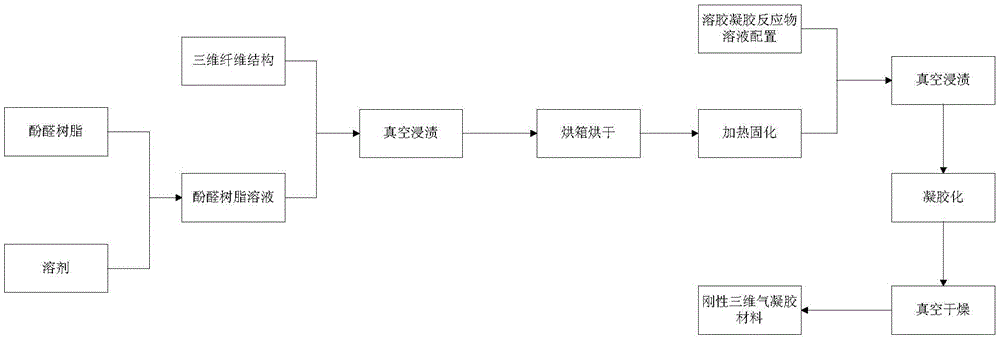

Method used

Image

Examples

Embodiment 1

[0055] First, dissolve the phenolic solution in ethanol in a vacuum impregnation vessel to form a phenolic solution with a phenolic mass content of 20%, then press the three-dimensional needle-punched glass fiber mat into the phenolic solution, and the solution completely submerges the three-dimensional needle-punched glass fiber, and the vacuum After the impregnation sealing cover is fixed with the vacuum impregnation container, vacuum impregnation is carried out, the vacuum pressure is 10kPa, after 10 minutes of immersion, the vacuum impregnation sealing cover is opened, and then left to stand for 10 minutes.

[0056] Next, take the three-dimensional needle-punched glass fiber mat out of the solution, dry it in the air without solution flow out, put it in an oven to dry at 60°C for 2 hours, and then cure it at 175°C for 2 hours to form a rigid three-dimensional needle-punched glass fiber structure.

[0057] Then, resorcinol, furfural and sodium hydroxide were dissolved in eth...

Embodiment 2

[0061] First, dissolve the phenolic solution in isopropanol in a vacuum impregnation vessel to form a phenolic solution with a phenolic mass content of 30%, then press the three-dimensional needle-punched carbon fiber felt into the phenolic solution, and the solution completely submerges the three-dimensional needle-punched carbon fiber felt, and Vacuum impregnation is carried out after the vacuum impregnation sealing cover is fixed with the vacuum impregnation container, the vacuum pressure is 8kPa, the vacuum impregnation sealing cover is opened after immersion for 5 minutes, and then left to stand for 5 minutes.

[0062] Then, the three-dimensional needle-punched carbon fiber mat was taken out of the solution, dried in the air without solution outflow, put into an oven for 1 hour at 80°C, and then cured at 200°C for 2 hours to form a rigid three-dimensional needle-punched carbon fiber structure.

[0063] Then, resorcinol, furfural and sodium hydroxide were dissolved in ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com