Preparation method for milk protein composite fiber, milk protein composite fiber and application

A milk protein and composite fiber technology is applied in the preparation of milk protein composite fibers, milk protein composite fibers and application fields, which can solve the problems of high cost of chemical fibers and insufficient comfort, and achieves strong process operability and repeatability. Strong and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

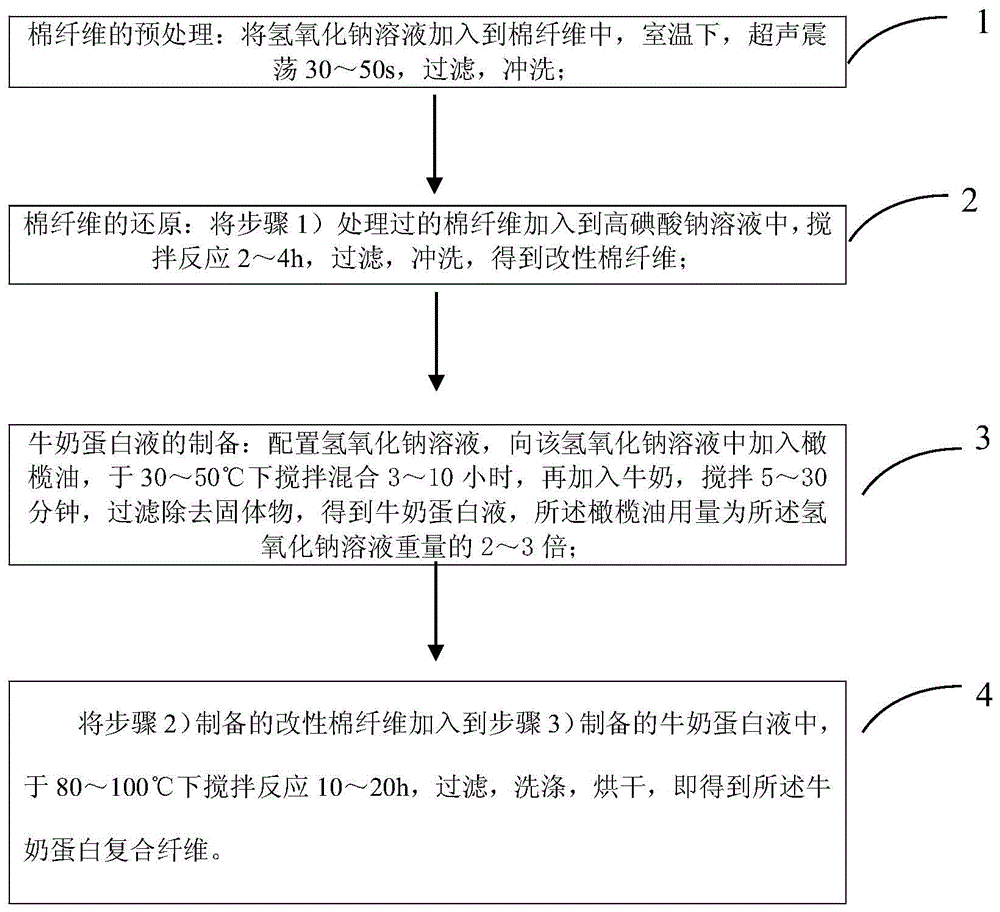

[0024] see figure 1 , shows the flow chart of the milk protein composite fiber preparation method of the embodiment of the present invention, the method includes the following steps:

[0025] 1) Pretreatment of cotton fiber: add sodium hydroxide solution to cotton fiber, at room temperature, ultrasonically vibrate for 30-50s, filter and rinse;

[0026] 2) Reduction of cotton fibers: adding the cotton fibers treated in step 1) into the sodium periodate solution, stirring for 2-4 hours, filtering, and rinsing to obtain modified cotton fibers;

[0027] 3) Preparation of milk protein liquid: prepare sodium hydroxide solution, add olive oil to the sodium hydroxide solution, stir and mix at 30-50°C for 3-10 hours, then add milk, stir for 5-30 minutes, filter to remove solid matter to obtain milk protein liquid, and the amount of olive oil is 2 to 3 times of the weight of the sodium hydroxide solution;

[0028] 4) Add the modified cotton fiber prepared in step 2) to the milk protei...

Embodiment 2

[0040] The milk protein composite fiber preparation method, fiber and application provided in this example are basically the same as those in Example 1, except that:

[0041] 1) Pretreatment of cotton fibers: adding a sodium hydroxide solution with a concentration of 15% by weight into the cotton fibers, the sodium hydroxide solution will completely immerse the cotton fibers, at room temperature, ultrasonically vibrate for 30s, filter, and rinse with deionized water 3 times;

[0042] 2) Reduction of cotton fiber: immerse the cotton fiber treated in step 1) into a sodium periodate solution with a concentration of 0.05% by weight, under dark conditions, stir and react for 2h, filter, and rinse with deionized water for 5 times , to obtain modified cotton fiber;

[0043] 3) Preparation of milk protein liquid: prepare sodium hydroxide solution, add olive oil to the sodium hydroxide solution, stir and mix at 30°C for 3 hours, then add milk, stir for 5 minutes, filter to remove solids...

Embodiment 3

[0047] The milk protein composite fiber preparation method, fiber and application provided in this example are basically the same as those in Example 1 or 2, except that:

[0048] 1) Pretreatment of cotton fiber: adding a sodium hydroxide solution with a weight percentage concentration of 20% to the cotton fiber, the sodium hydroxide solution will completely immerse the cotton fiber, at room temperature, ultrasonically vibrate for 40s, filter, and rinse with deionized water 3 times;

[0049] 2) Reduction of cotton fiber: immerse the cotton fiber treated in step 1) into a sodium periodate solution with a concentration of 0.12% by weight, under dark conditions, stir and react for 3h, filter, and rinse with deionized water for 5 times , to obtain modified cotton fiber;

[0050] 3) Preparation of milk protein liquid: configure sodium hydroxide solution, add olive oil to the sodium hydroxide solution, stir and mix at 40°C for 8 hours, then add milk, stir for 20 minutes, filter to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com