Sewage treatment method with enhanced denitrification and dephosphorization functions

A sewage treatment method and technology for denitrification and phosphorus removal, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. Phosphorus requirements, mud age contradictions and other issues, to achieve the effect of significant sludge reduction, strong shock load resistance, and carbon source reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

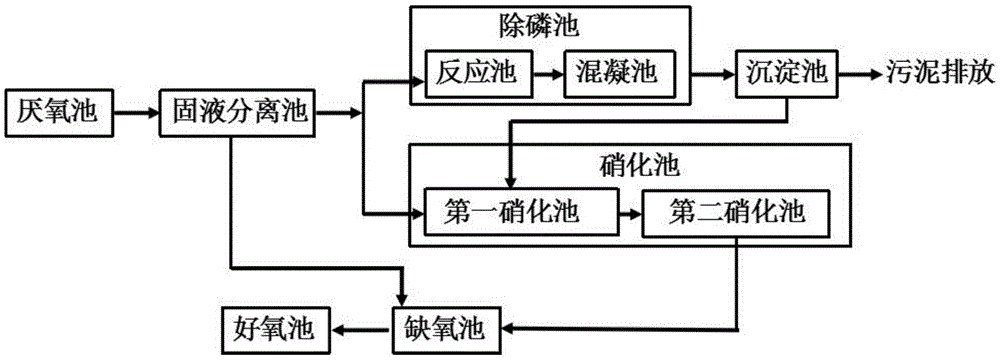

Image

Examples

Embodiment 1

[0029] The phosphorus removal tank in the step S2 is composed of a reaction tank and a coagulation tank, and 10% of the supernatant produced by the solid-liquid separation tank is introduced into the reaction tank for treatment and then into the coagulation tank for processing. During the process, the reaction tank and the coagulation tank need to be aerated.

[0030] The dephosphorization agent added in the reaction tank is ferric chloride, and it needs to be fully stirred during the dosing process, so that the phosphate substance in the reaction tank is precipitated in the form of iron phosphate; the coagulation tank is added The coagulant used is polyacrylamide, and the polyacrylamide can absorb the ferric phosphate precipitate that enters the coagulation tank, so that it can be precipitated as flocculent particles with larger particles, and the ferric phosphate precipitate that is beneficial to be formed can be The settling tank is completely settled, so that the ferric ph...

Embodiment 2

[0034] As the sewage treatment method for efficient denitrification and phosphorus removal described in Example 1, the difference of this embodiment is that the phosphorus removal tank in the step S2 is composed of a reaction tank and a coagulation tank, and the solid-liquid separation tank 12% of the supernatant produced is introduced into the reaction tank for treatment and then into the coagulation tank for treatment. During the treatment, the reaction tank and the coagulation tank need to be aerated.

[0035] The dephosphorization agent added in the reaction tank is ferric sulfate, and it needs to be fully stirred during the dosing process, so that the phosphate substance in the reaction tank is precipitated in the form of iron phosphate; the mixing tank added in the coagulation tank The coagulant is polyaluminum chloride, and the polyaluminum chloride can absorb the ferric phosphate precipitation entering the coagulation tank, so that it can be precipitated in flocculent f...

Embodiment 3

[0037] As the sewage treatment method for efficient denitrification and phosphorus removal described in Example 2, the difference of this embodiment is that the phosphorus removal tank in the step S2 is composed of a reaction tank and a coagulation tank, and the solid-liquid separation tank 15% of the generated supernatant is introduced into the reaction tank for treatment and then into the coagulation tank for treatment. During the treatment, the reaction tank and the coagulation tank need to be aerated.

[0038] The dephosphorization agent added in the reaction tank is lime, and it needs to be fully stirred during the dosing process, so that the phosphate substance in the reaction tank is precipitated in the form of calcium phosphate; the coagulation added in the coagulation tank The agent is polyferric sulfate, and the polyferric sulfate can be adsorbed into the calcium phosphate precipitate in the coagulation tank, so that it is precipitated with larger particles of floccul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com