Full-automatic liquid-liquid douche bag making filling-sealing machine

A fully automatic, flushing bag technology, applied in the direction of liquid materials, packaging, packaging items, etc., can solve the problems of undesigned, unable to make bags with flushing function, and not equipped with flushing function in production, so as to achieve high production efficiency , Reasonable equipment layout and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

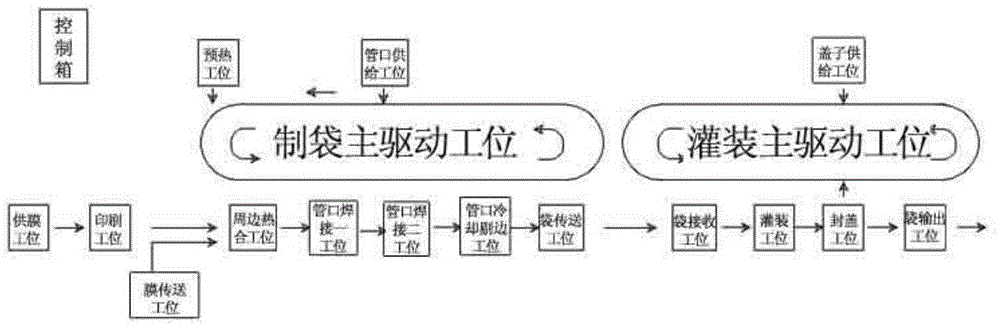

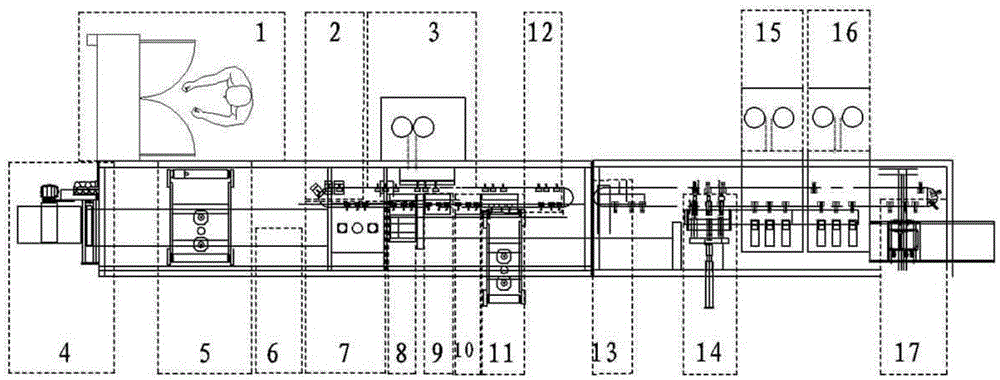

[0041] Such as image 3 A fully automatic liquid-liquid flushing bag making and filling machine is shown, which includes a control part 1 and an execution part. The control part 1 is composed of a man-machine interface, a programmable controller with storage conditions, a temperature control device, a medicine It is composed of a liquid filling control device, a servo control device and a signal input and output bus device; the execution parts include the film supply station 4, the bag body printing station 5, the film transfer station 6, the main driving station for bag making and the filling station. Bag main driving station, the bag making main driving station is related to the bag filling main driving station in a linear manner; the bag making main driving station includes nozzle supply station 3, nozzle pre-welding station in turn Position 2, bag body contour welding station 7, nozzle welding station, bag body shaping waste edge removal station 10, chamber isolation bar w...

Embodiment 2

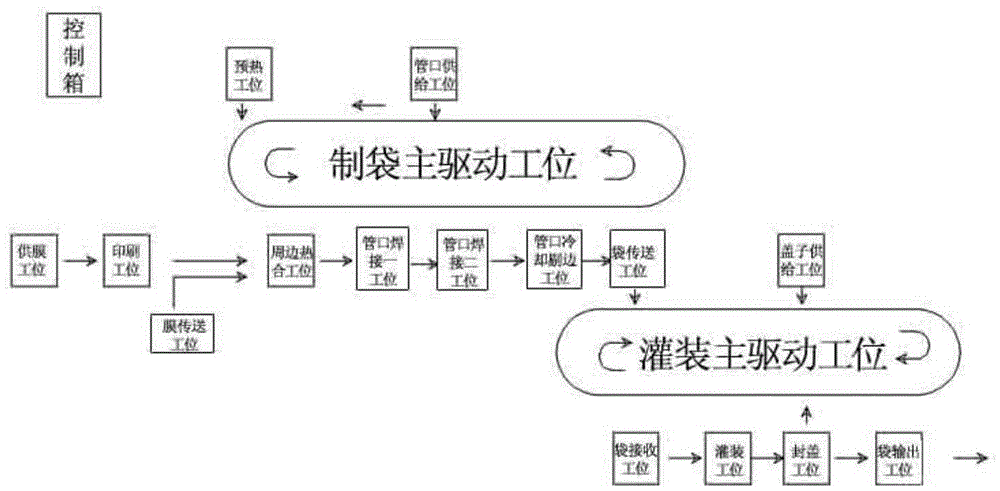

[0068] The difference between the fully automatic liquid-liquid flushing bag making and filling machine of this embodiment and that of Embodiment 1 is that the main driving station of bag making and the main driving station of bag filling are related in a dislocation manner;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com